Oil displacement profile control agent, displacement of reservoir oil system and displacement of reservoir oil method

A technology for adjusting flooding agent and foam, which is applied in chemical instruments and methods, production fluids, and earthwork drilling, etc. It can solve the problem that the recovery rate of the interfacial tension between crude oil and water is not high enough, the polymer flooding cannot be greatly reduced, and the impact of problems such as normal production of oil wells, to achieve the effects of improving crude oil recovery, reducing oil production costs, and increasing sweeping coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

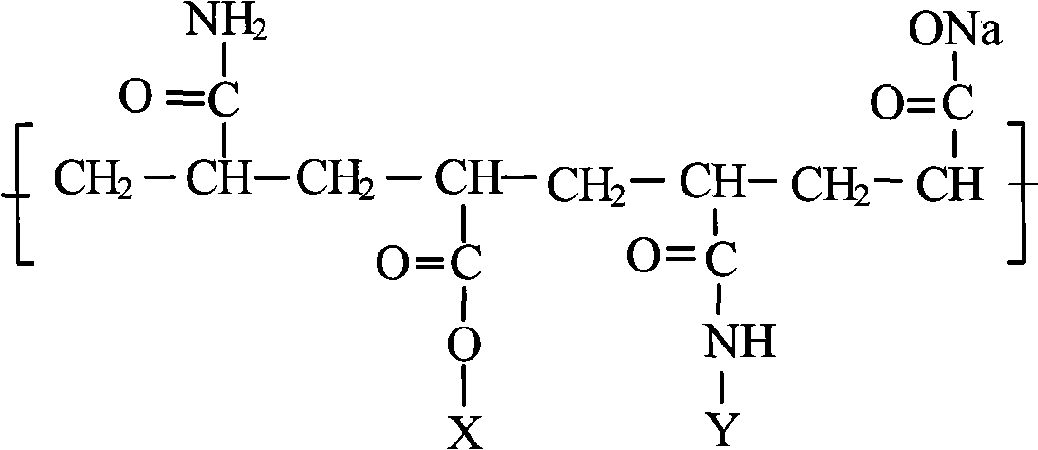

[0038] Embodiment one, the preparation of foam regulating and displacing agent

[0039]1. Displacing agent 1: polymer 1-alkylbenzene sulfonate sodium 0.1wt% foam displacing agent. Take 500 mg of polymer 1 (purchased from Shanghai Haibo Co., Ltd. functional polymer type I, viscosity greater than 100 mPa.s), 1 mg of sodium alkylbenzene sulfonate, mix and add 1 L of water to dissolve, and obtain 1 L of foam control agent solution, which is A polymer 1-alkylbenzenesulfonate sodium foam control agent solution with a blowing agent concentration of 0.1 wt%.

[0040] 2. Flooding agent 2: polymer 2-alkyl sulfonate sodium 0.2wt% foam regulating agent. Take 500mg of polymer 2 (purchased from Shanghai Haibo Co., Ltd. functional polymer type II, with a viscosity greater than 50mPa.s), 2mg of sodium alkylsulfonate, mix them and add 1L of water to dissolve them to obtain 1L of foam control agent solution. Foaming agent adding amount (concentration) is 0.2wt% polymer 2-alkylbenzenesulfonate...

Embodiment 2

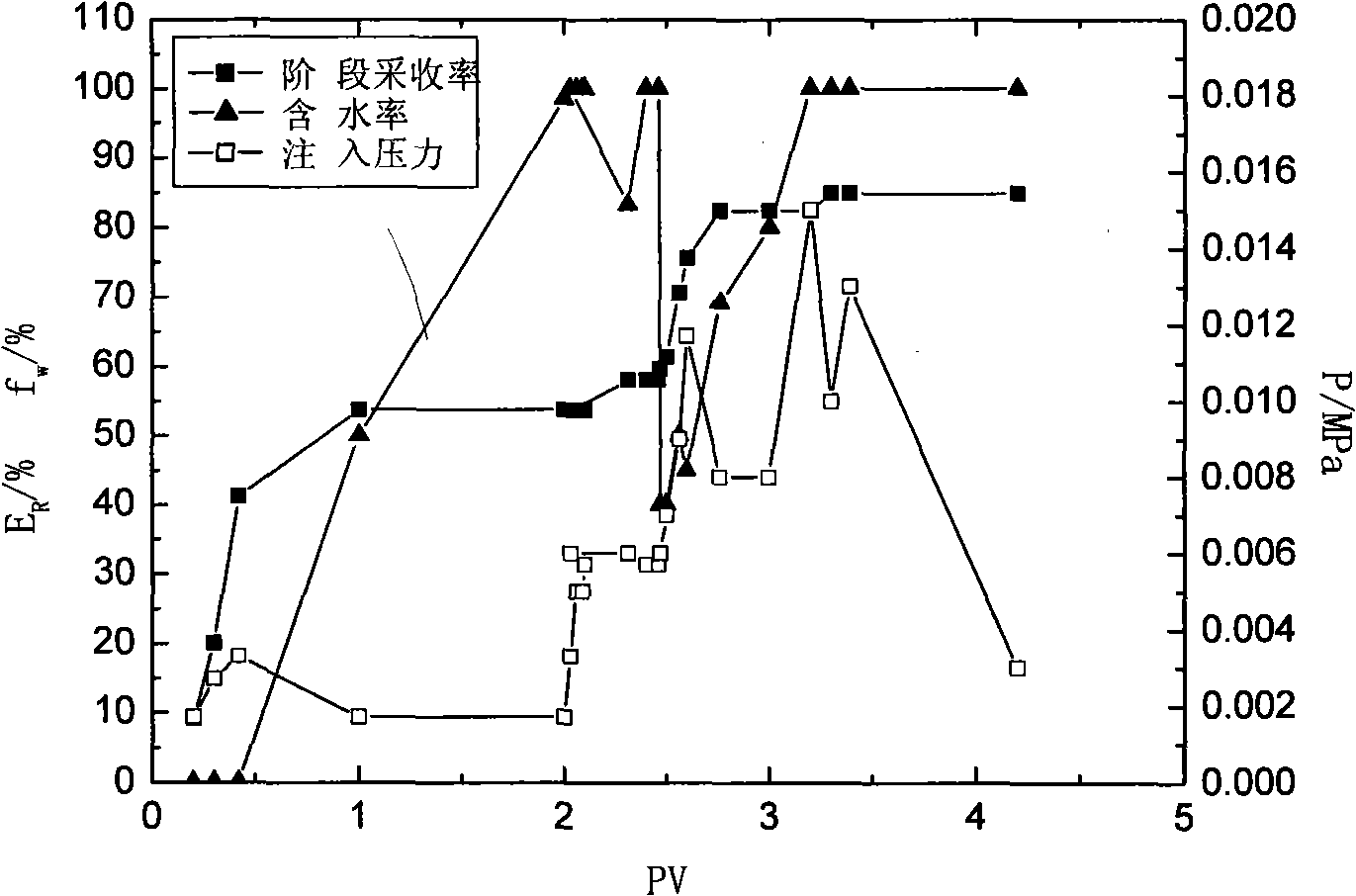

[0044] Example 2. Oil displacement experiment of heterogeneous core polymer-foam displacement system

[0045] Indoor physical simulation experiments are adopted.

[0046] Experimental conditions:

[0047] Heterogeneous core: 4.5×4.5×30cm, gas permeability of three layers are 100md, 1000md, 3000md respectively.

[0048] Oil: simulated crude oil, the viscosity is 10mPa·s at 45°C;

[0049] Water: Oilfield sewage;

[0050] Adjusting and displacing agent: according to embodiment 1 preparation;

[0051] Experimental temperature: 45°C;

[0052] Foam: The volume ratio of foam control agent and compressed air is 1:1;

[0053] Polymer: the functional polymer in Example 1.

[0054] experimental method:

[0055] Water drives the core to a moisture content of over 98%. After the 2PV of water flooding in the early stage, the combination slug is injected, followed by: 0.07PV polymer (viscosity 1500mPa.s), 0.01PV polymer (viscosity 560mPa.s), 0.15PV polymer (51mPa.s), and then injecte...

Embodiment 3

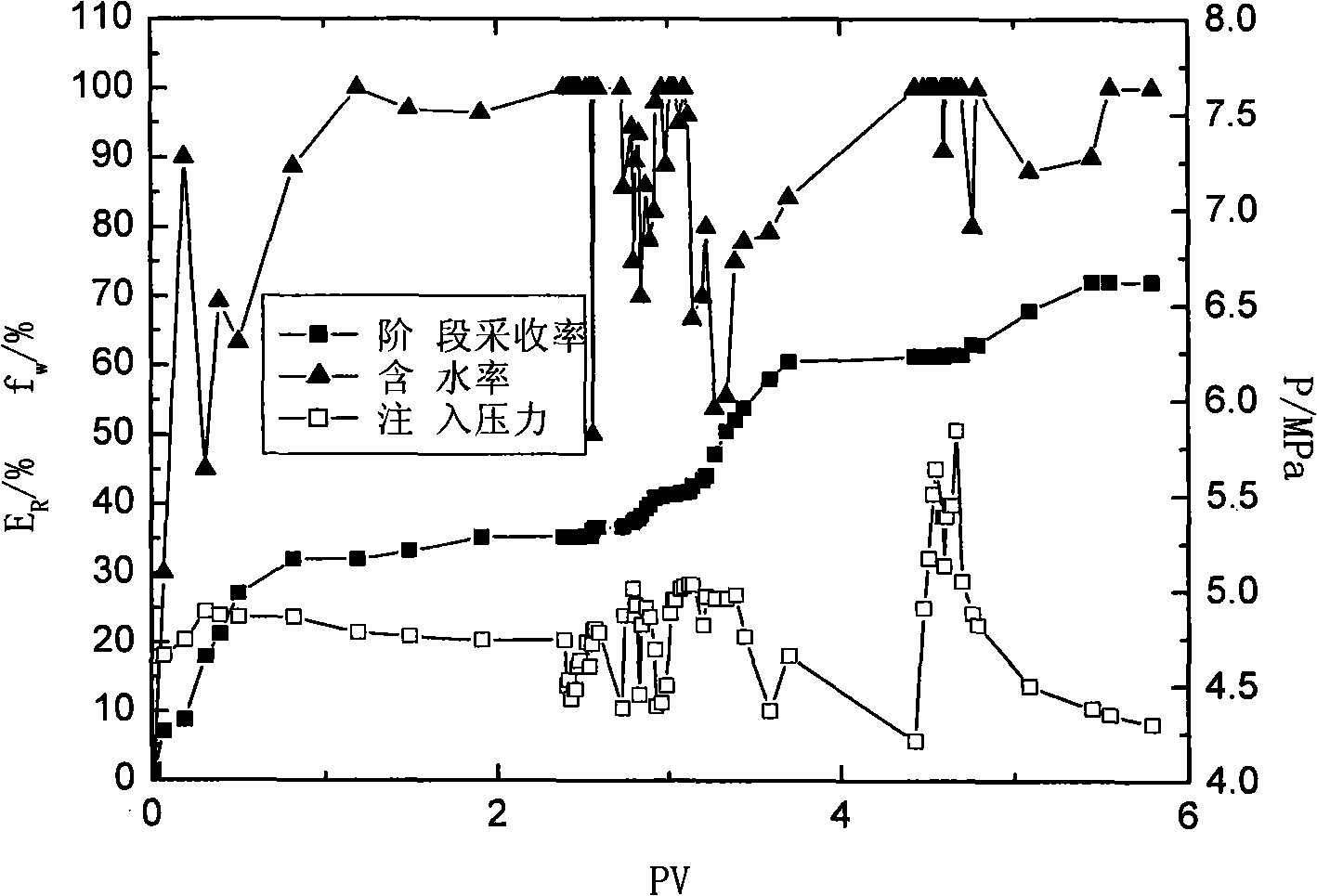

[0058] Example three: the same experimental conditions and methods as in Example two, the combined slugs are as follows: water flooding 1.41PV, injection of 0.07PV, 1500mg / L type I functional polymer (viscosity 1500mPa.s); 0.01PV, 1500mg / LIII type functional polymer (viscosity 560mPa.s); 0.15PV, 1000mg / LIII type functional polymer (51mPa.s); Note 0.1PV, 1500mg / L type II functional polymer (viscosity 1400mPa.s); 0.01 PV, 1500mg / L III functional polymer (viscosity 560mPa.s); 0.10PV, 1000mg / L III functional polymer (51mPa.s); 0.3PV foam (0.3% blowing agent + 500mg / L III functional polymer material); the follow-up water flooding was 1.20PV, and the injected foam control and flooding agent solution was 0.3PV polymer 1-alkylbenzene sulfonate sodium 0.1wt% foam control and flooding agent.

[0059] The oil displacement results show that the use of functional polymer foam flooding can increase the recovery rate by more than 38% on the basis of water flooding, and the total recovery ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com