Screw preparation machine

A preparation machine and screw technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of wasting manpower, shaking for a long time, and low efficiency, and achieve the effect of saving manpower, improving efficiency, and simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

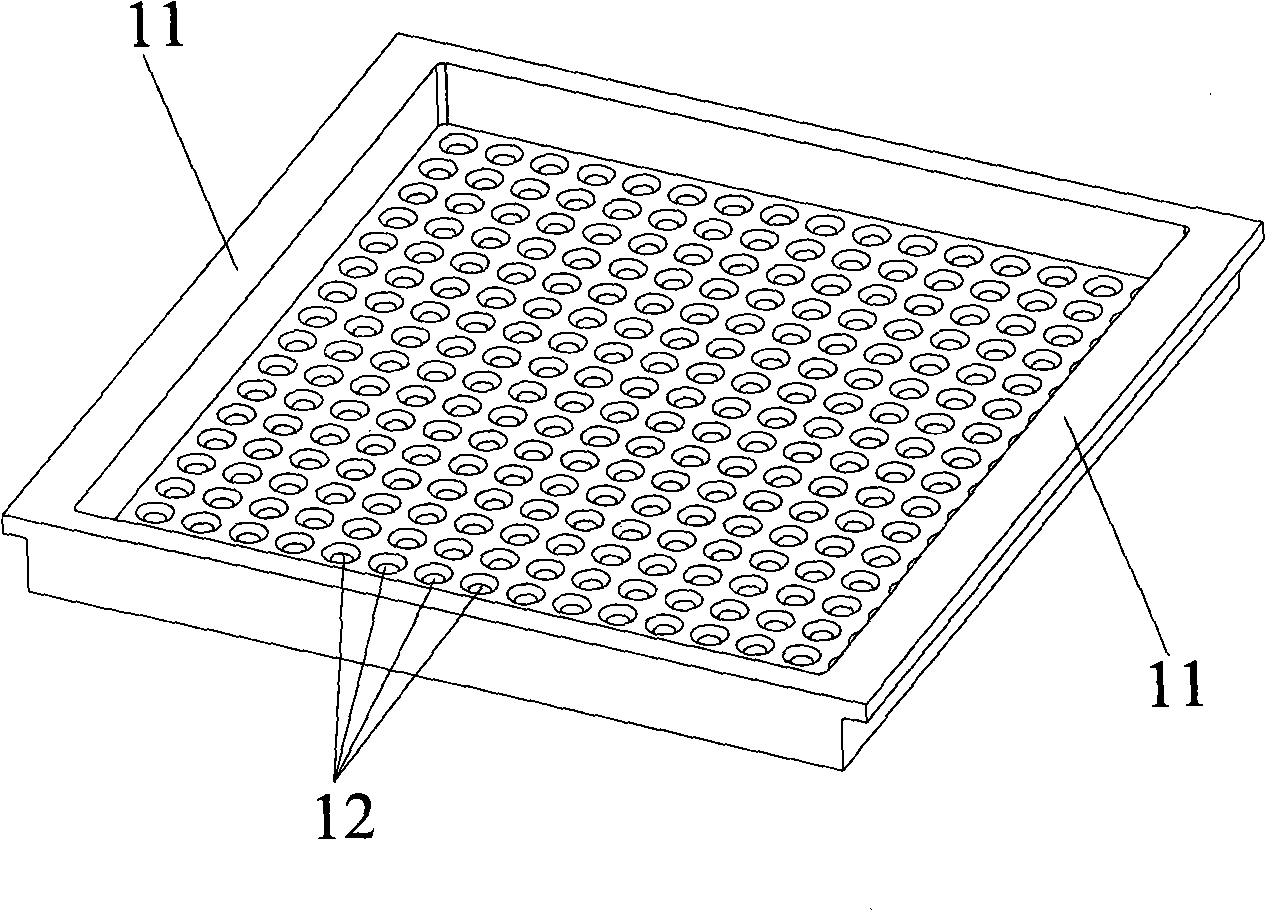

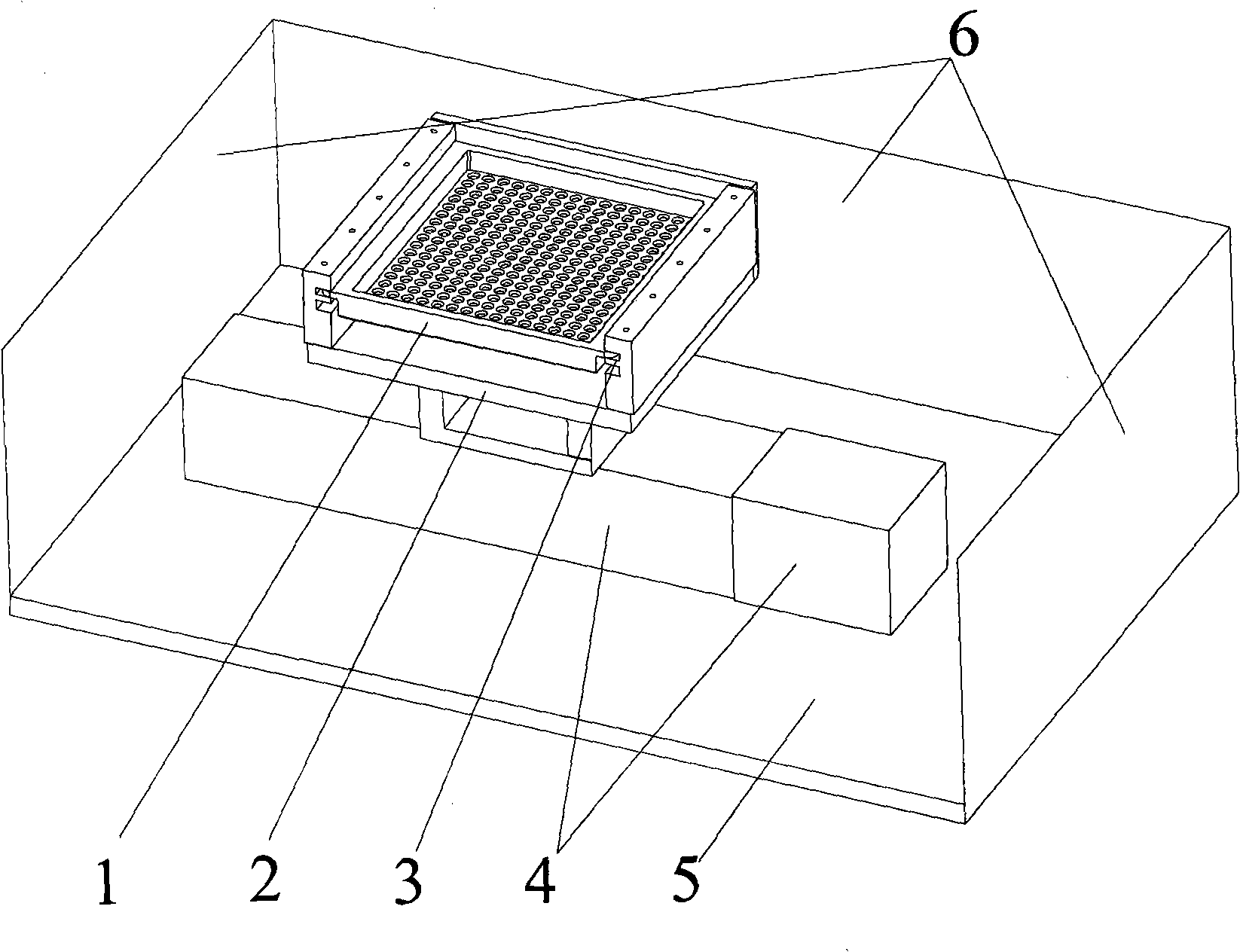

[0022] The screw preparation machine is to mechanically shake the screw tray, so that the screws in the screw tray are shaken into some screw preparation holes 12 on the screw tray 1, so as to improve the work efficiency in the subsequent screwing process. The screw preparation machine of the specific embodiment of the present invention, as figure 2 As shown, it includes a bottom plate 5 and a shaking device 4; the bottom plate 5 is used to fix the fixed part of the shaking device 4, and the movable part of the shaking device 4 drives the screw tray 1 to shake.

[0023] There are many kinds of devices for shaking, and in a preferred technical solution, the shaking device is a reciprocating device. Pneumatic, hydraulic or electric can be used. In principle, as long as reciprocating motion can be generated, in a further preferred technical solution, the reciprocating device is a reciprocating oil cylinder, a reciprocating air cylinder, or a servo shaft. This specific embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com