Vehicle bottom board of composite material

A composite material and vehicle technology, which is applied to vehicle components, superstructures, superstructure subassemblies, etc., can solve the problems of unsatisfactory thermal insulation performance, poor sound insulation, noise insulation, vibration isolation performance, heavy weight, etc. problem, to achieve the effect of light weight, increased load capacity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A floor plate for cars is one of the composite material vehicle floor plates involved in this paper. The panel 1 is formed by curing epoxy resin and carbon fiber, and the core material 2 is PVC foam. Process the corresponding mold according to the need, and treat the surface of the mold accordingly. Lay the bottom layer of carbon fiber, PVC foam, and top layer of carbon fiber on the surface of the mold, seal the mold, and fill the mold with epoxy resin. After the resin is completely cured, the composite bottom plate can be taken out, and it can meet the requirements after a little modification.

Embodiment 2

[0024] A passenger car bottom plate is one of the composite material vehicle bottom plates involved in this paper. The panel 1 is formed by curing vinyl resin and glass fiber, and the core material 2 is Balsa balsa wood. The bottom plate for passenger cars is generally a flat plate, and a platform is selected as a mold according to its needs, and the corresponding surface treatment is carried out on the mold. Lay vinyl-impregnated fiberglass on the countertop, top with balsa wood, and then resin-impregnated fiberglass. After the laying is completed, the test piece is sealed, and the excess resin is extracted. After the resin is completely cured, the required vehicle floor can be formed.

Embodiment 3

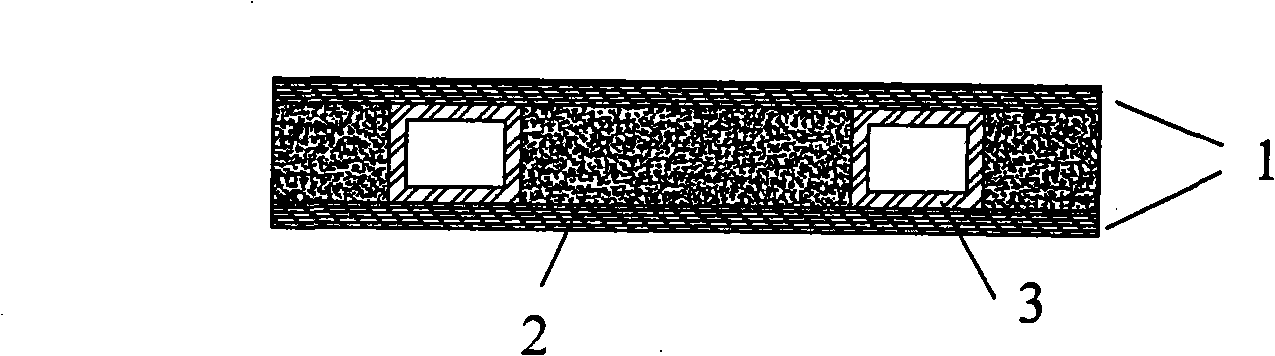

[0026] A compartment floor for trucks, which is one of the composite material vehicle floors involved in this paper, its panel 1 is made of vinyl resin and glass fiber solidified, the core material 2 is foam wood, and the core material 2 is placed at intervals There are FRP square tubes 3. The bottom plate of the truck compartment is generally a large-area flat plate, which needs to be spliced by multiple flat plates. Select a platform as the mold according to its needs, and carry out corresponding surface treatment on the mold. Spread the glass fiber impregnated with vinyl resin on the table top, pave paulownia wood on the surface, arrange the glass fiber reinforced plastic square tubes 3 at intervals, and spread the glass fiber impregnated with resin again. After the laying is completed, an appropriate amount of pressure is applied to the surface of the specimen to ensure its molding quality. After the resin in the test piece is completely cured, the required vehicle flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com