Method for producing cleaning blade for use in image-forming apparatus and cleaning blade

A technology for cleaning blades and imaging devices, which is applied in the field of cleaning blades and can solve problems such as the impossibility of obtaining cleaning blades with suitable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0140] After weighing the rubber component (1) in the amount shown in Table 1, the rubber component (1) was added to a rubber kneading device, which was then heated to 60 to 110°C and kneaded for 0.5 to 6 minutes.

[0141] After weighing the filler (2) and the crosslinking agent (3) in the amounts shown in Table 1, the filler (2) and the crosslinking agent (3) were added to the rubber kneading device. Then, the filler (2), the crosslinking agent (3), and the rubber component (1) are heated to 60 to 110°C and kneaded for 0.5 to 10 minutes.

[0142] After the obtained thermosetting elastomer composition is placed in a hard mold, it is press-vulcanized at a temperature of 160-170° C. for 30 minutes to produce a thin plate with a thickness of 2 mm.

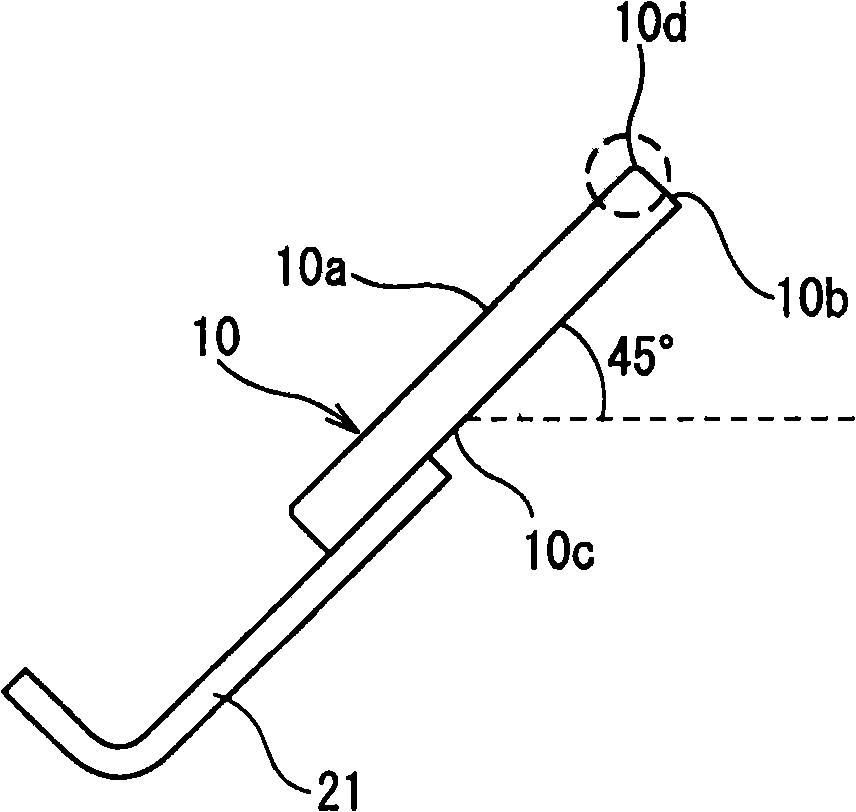

[0143] After cutting out a cleaning blade with a width of 27 mm and a length of 320 mm from a thin plate with a thickness of 2 mm, the cleaning blade and a support member made of chromium-free SECC were bonded together by a thermal fusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com