Positioning method for trunnion shaft assembly phase point

A positioning method and technology for balancing shafts, which are used in static/dynamic balance testing, measuring devices, and machine/structural component testing. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

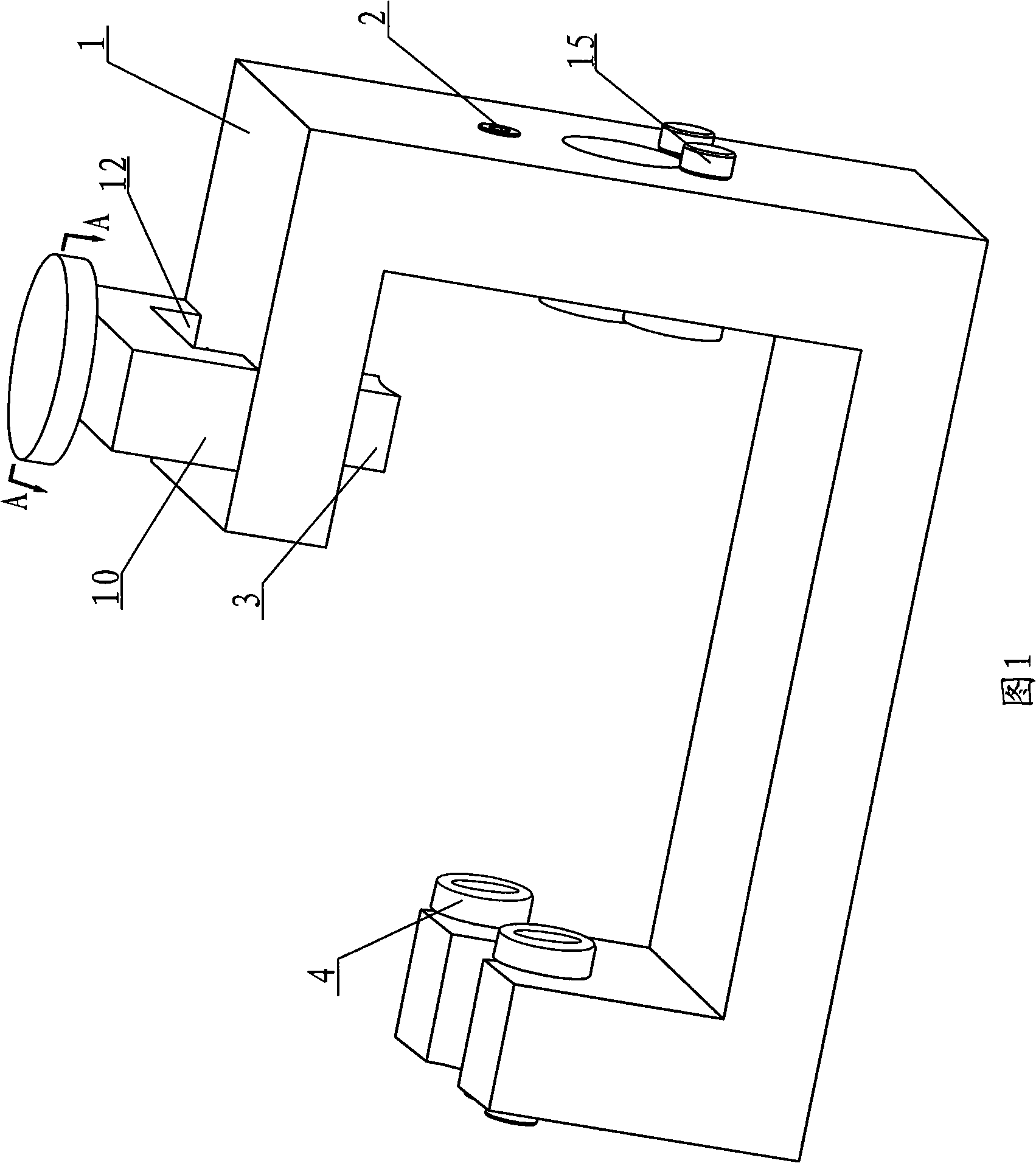

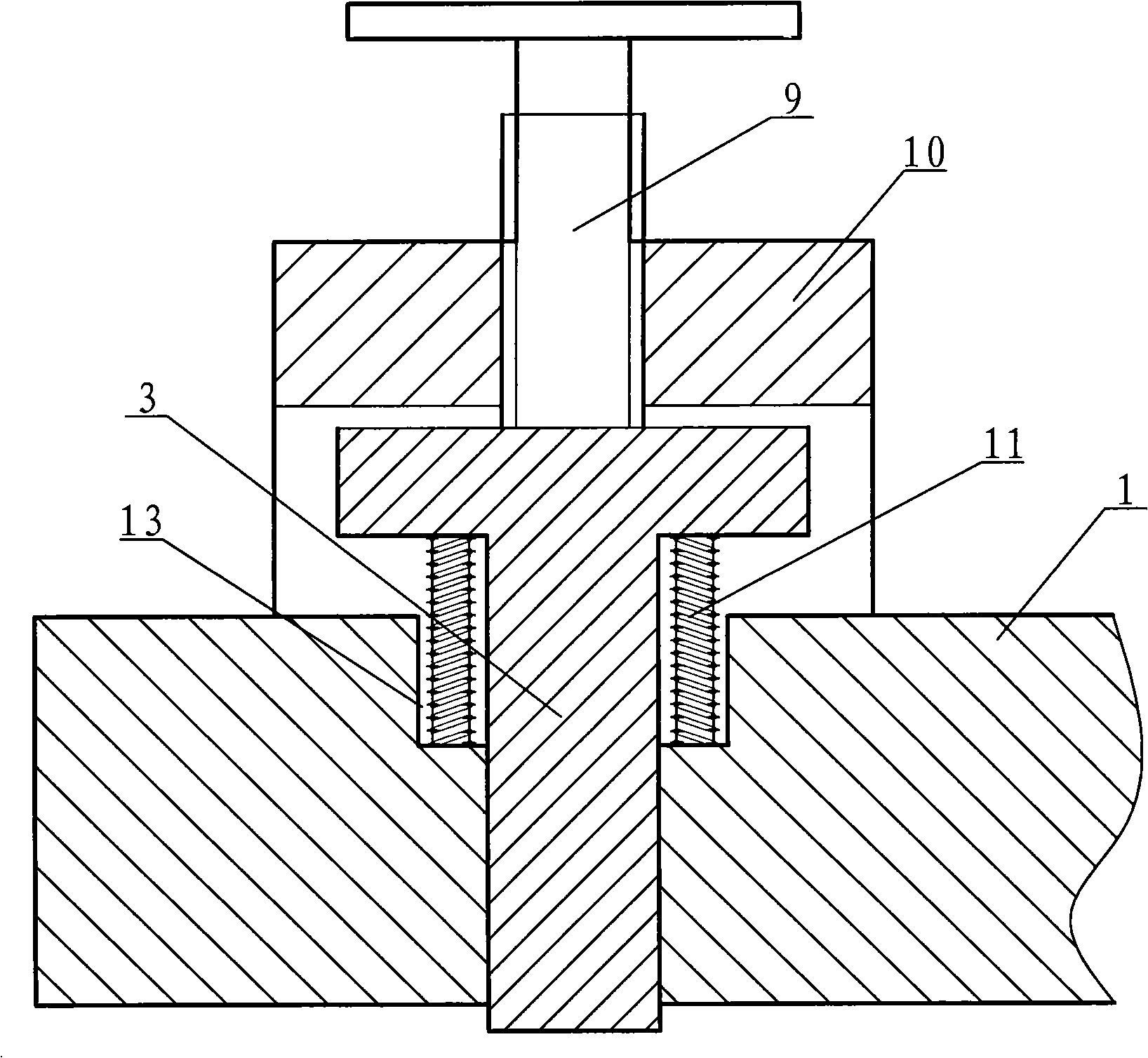

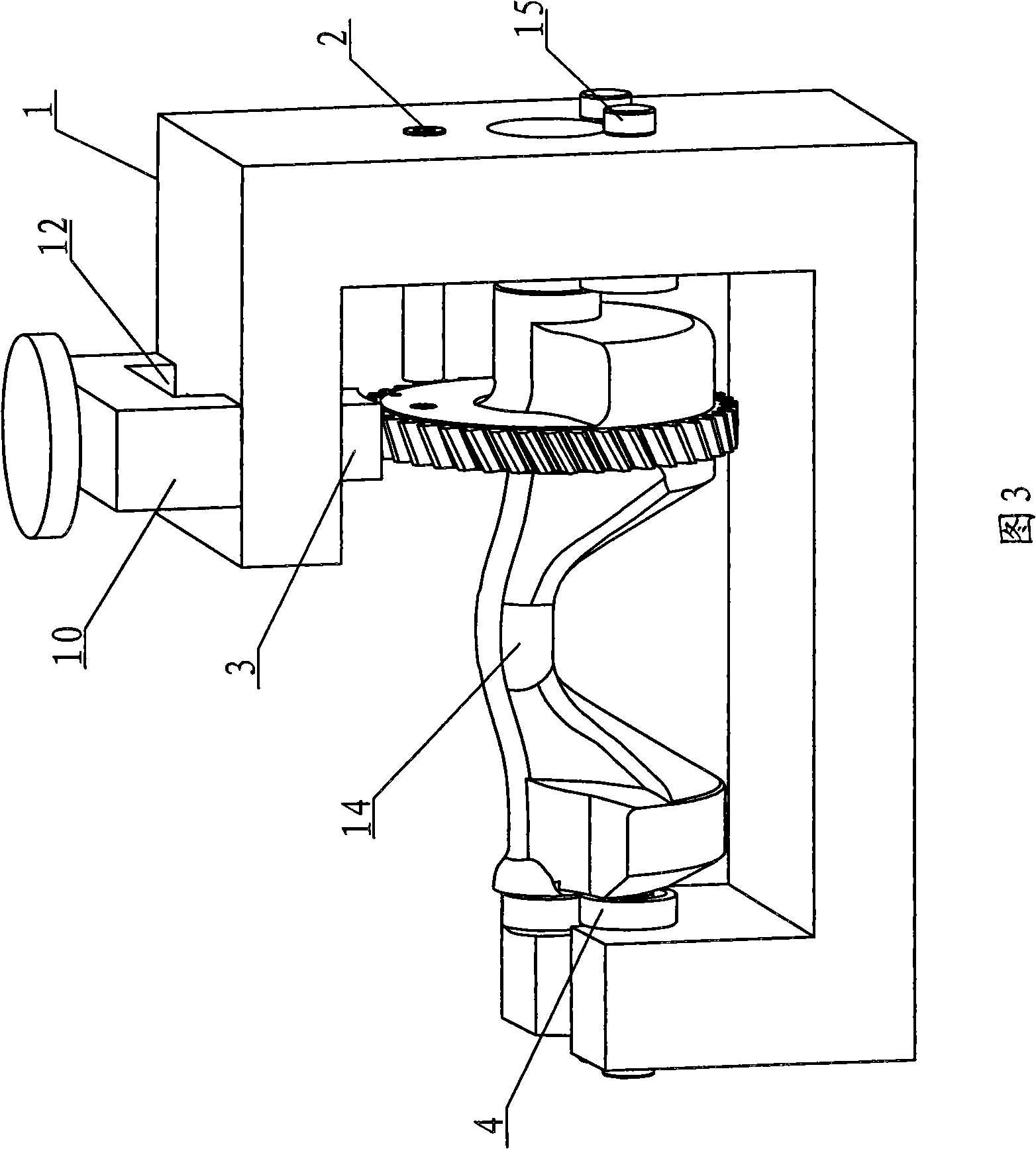

[0030] Embodiment 1, as shown in Figures 1 and 3, the supporting mechanism is two rolling bearings 4 arranged in parallel, and the two rolling bearings 4 are installed on the frame 1 through the shaft 15, and the distance between the two rolling bearings 4 is smaller than that of the journal end of the balance shaft 14. diameter. The journal ends of the balance shaft 14 are placed on the two rolling bearings 4 . The friction between the rolling bearing and the balance shaft 14 is relatively small, almost zero, and the counterweight on the balance shaft 14 is in a freely hanging state.

Embodiment 2

[0031] Embodiment 2, as shown in Figure 4, the support mechanism is a thimble structure, the thimble 7 is inserted in the thimble holes at both ends of the balance shaft 14 from the axial direction, the contact surface between the balance shaft 14 and the thimble is small, and the balance shaft 14 is supported on Free swing can be realized on the thimble, and the counterweight on the balance shaft 14 is in a freely hanging state during static balance.

Embodiment 3

[0032] Embodiment 3, as shown in FIG. 5 , the supporting mechanism is a V-shaped groove structure. Place the two ends of the balance shaft 14 in the V-shaped groove respectively. The two sides of the V-shaped groove 8 should be as smooth as possible. When the two ends of the balance shaft 14 are supported in the V-shaped groove 8, they can swing freely. The counterweight on the 14 is in free-hanging state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com