Process for synthesizing triformol using ionic liquid

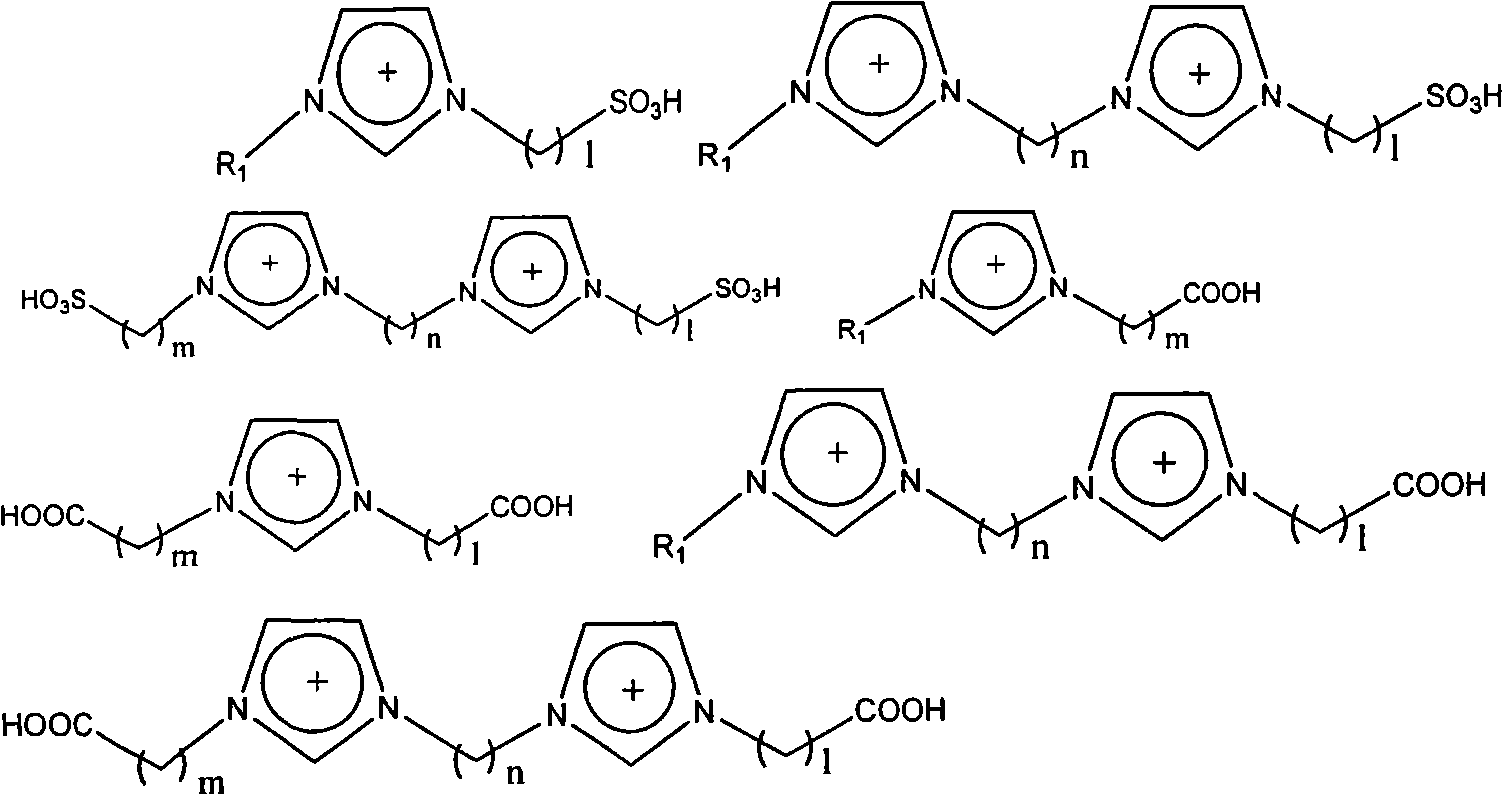

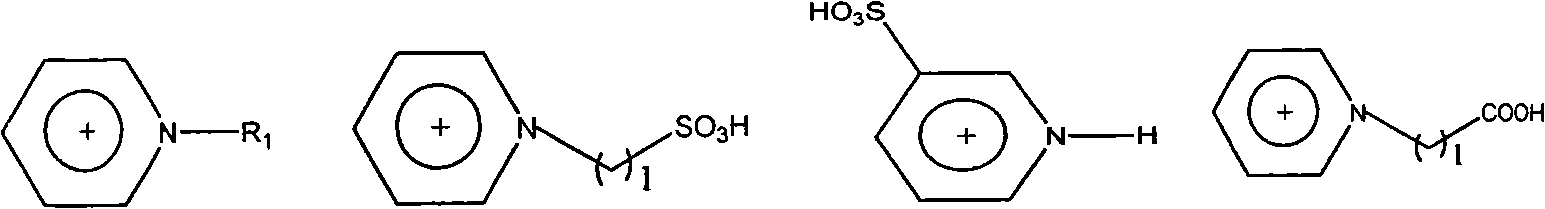

An acidic ionic liquid, cation technology, applied in chemical instruments and methods, preparation of organic compounds, organic compounds/hydrides/coordination complex catalysts, etc. Low, easy-to-prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In a 250ml reactor, 100g of 60.1% formaldehyde solution (containing methanol 1.2%) and 4.1g of catalyst a were added successively. Heat to reflux for 4 hours, adjust the reflux ratio R=2, formaldehyde, product paraformaldehyde and water azeotrope are distilled from the top of the tower, and at the same time add 50g of 60.1% formaldehyde solution (feed rate: 0.5mL / min). The temperature at the bottom of the rectification tank was 96-97°C, the temperature at the top of the tower was 92-93°C, and the material was discharged for 3 hours. According to chromatographic analysis, the content of paraformaldehyde in the distillate was 17.8%, the content of methanol was 0.9%, and the content of methylal was 0.2%.

Embodiment 2

[0042] With embodiment 1, use 2.0g catalyst b, add in the formaldehyde solution (containing methanol 1.5%) of 200g 50.3%, bottom temperature 96-97 ℃, tower top temperature 92-93 ℃, paraformaldehyde in the distillate The content of methanol is 18.2%, the content of methanol is 1.7%, and the content of methylal is 0.8%.

Embodiment 3

[0044] Same as in Example 1, using 2.5g of catalyst c, added to 110g of 50.3% formaldehyde solution (containing 1.5% methanol), the temperature at the bottom of the tank was 96-97°C, the temperature at the top of the tower was 91-92°C, and the paraformaldehyde in the distillate was The content of methanol is 26.1%, the content of methanol is 1.1%, and the content of methylal is 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com