Lighting device and method for directing light

A lighting device and device technology, applied in lighting and heating equipment, components of lighting devices, lighting devices, etc., can solve problems such as complex cost and high manufacturing process, and achieve the effect of fewer parts and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

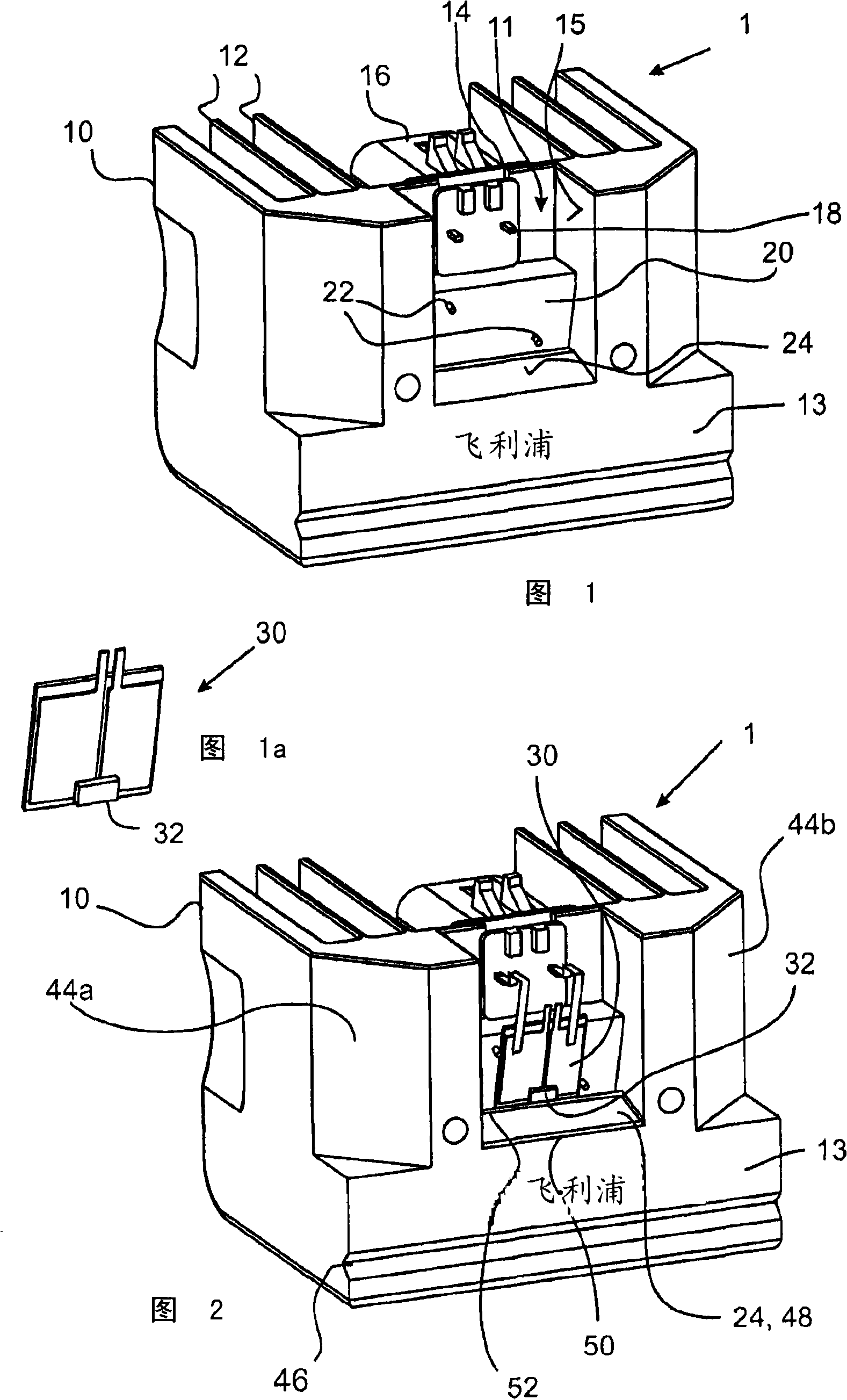

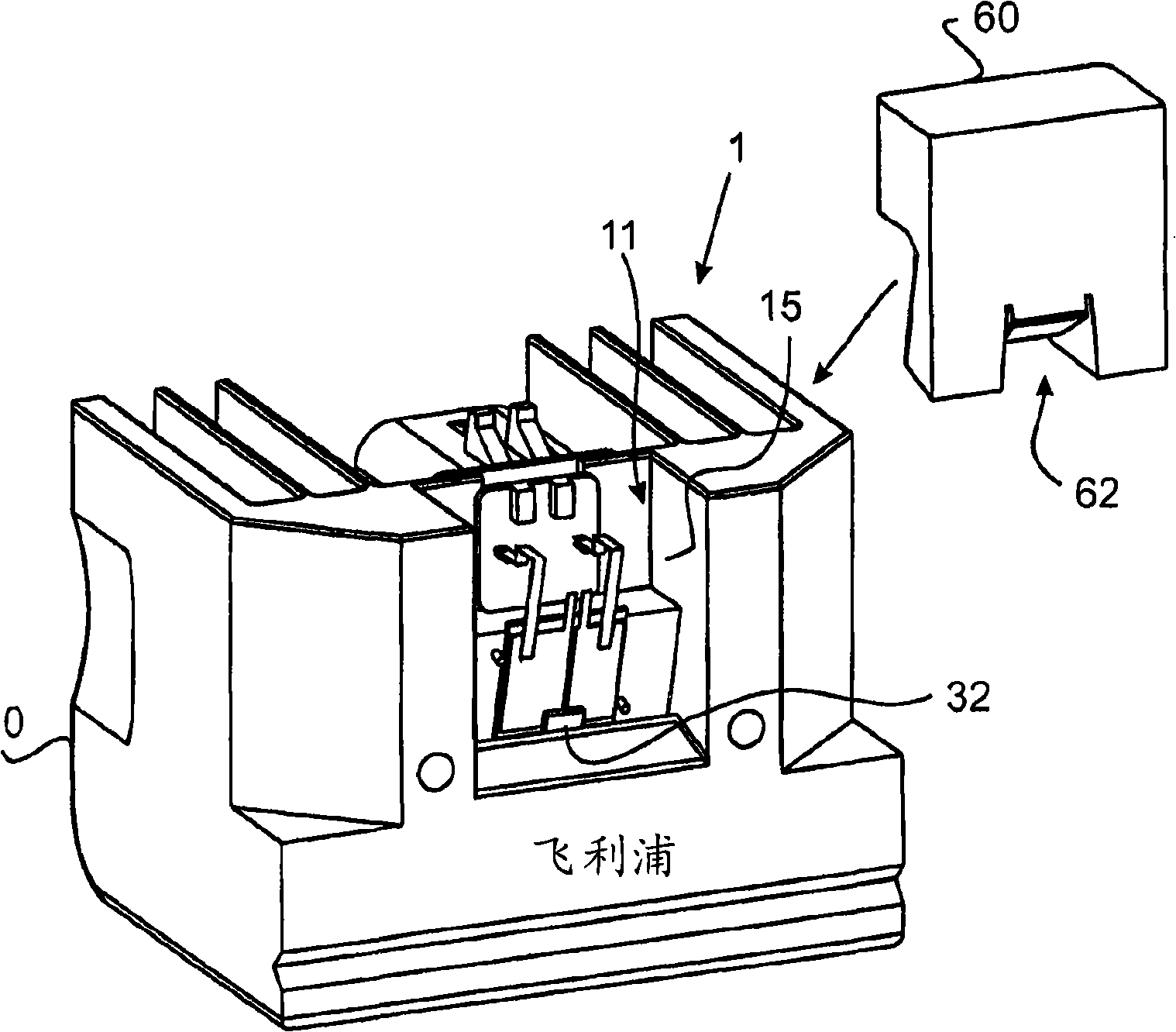

[0035]FIG. 1 shows a base portion 10 of a lighting device 1 , which is also referred to as an LED module 1 in this specification. The base portion 10 is made of aluminum. The base has the function of a heat sink. The base is equipped with a heat dissipation structure, which includes cooling fins 12 . A light-dark dividing line 14 is formed on the top portion of the base 10 in which the connector portion 16 is accommodated. The connector 16 is a plastic part comprising a plug (on the back side of the connector 16 , not shown in FIG. 1 ) and two contacts 18 which are electrically connected to the plug.

[0036] The base 10 comprises a cavity 11 provided in a front surface 13 of the base 10 , the cavity 11 being bounded by a side wall 15 . At the bottom of cavity 11 is a mounting surface 20 with two alignment pins 22 . A surface 24 for a reflective surface is arranged behind the mounting surface 20 .

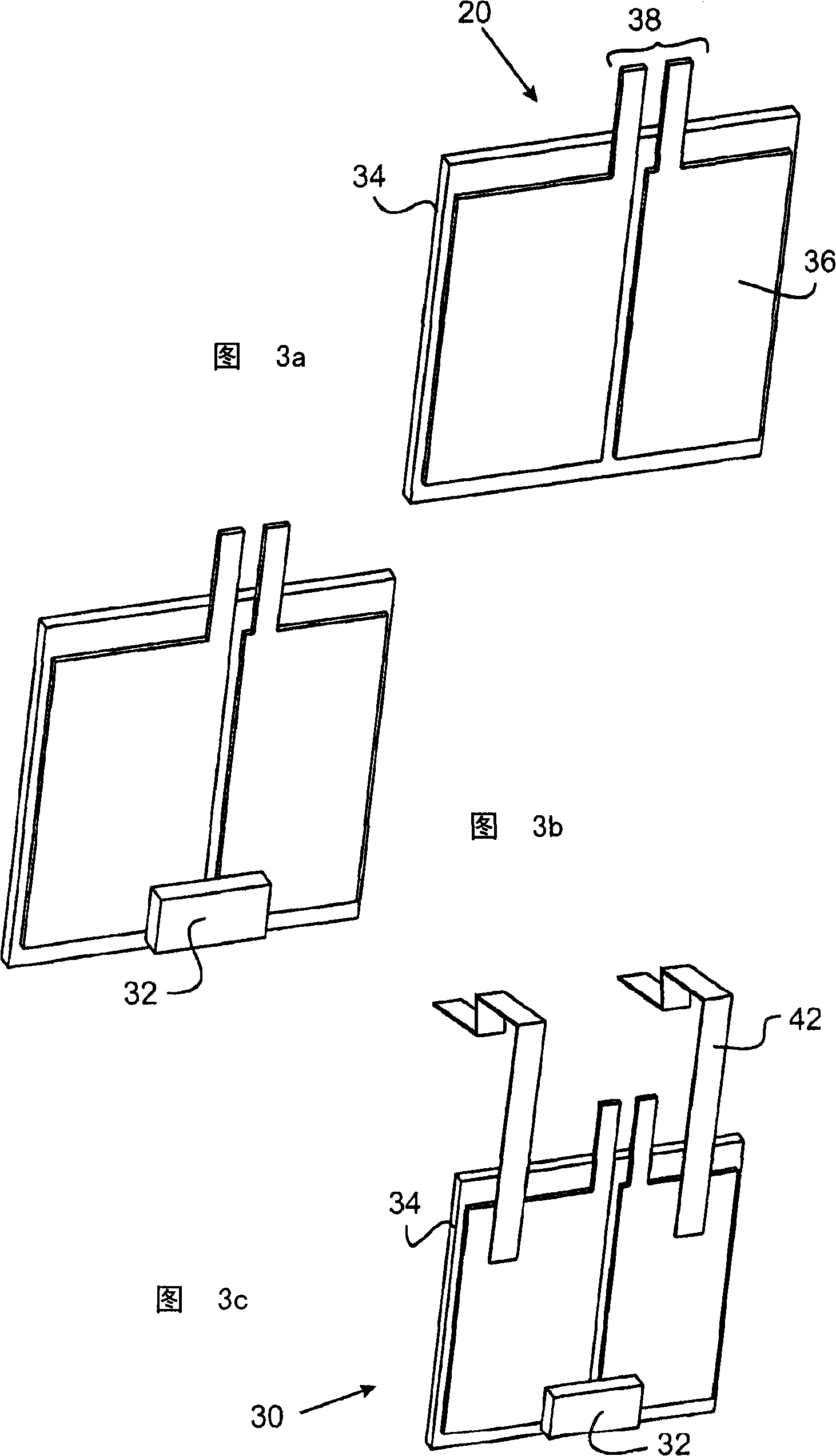

[0037] FIG. 1 a shows an LED lighting element 30 comprising an LED 32 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com