Gas valve of tubular solenoid

A solenoid and gas technology, applied in the direction of electromagnets, valve details, valve devices, etc., can solve the problem of increasing the solenoid group and achieve the effect of avoiding missing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

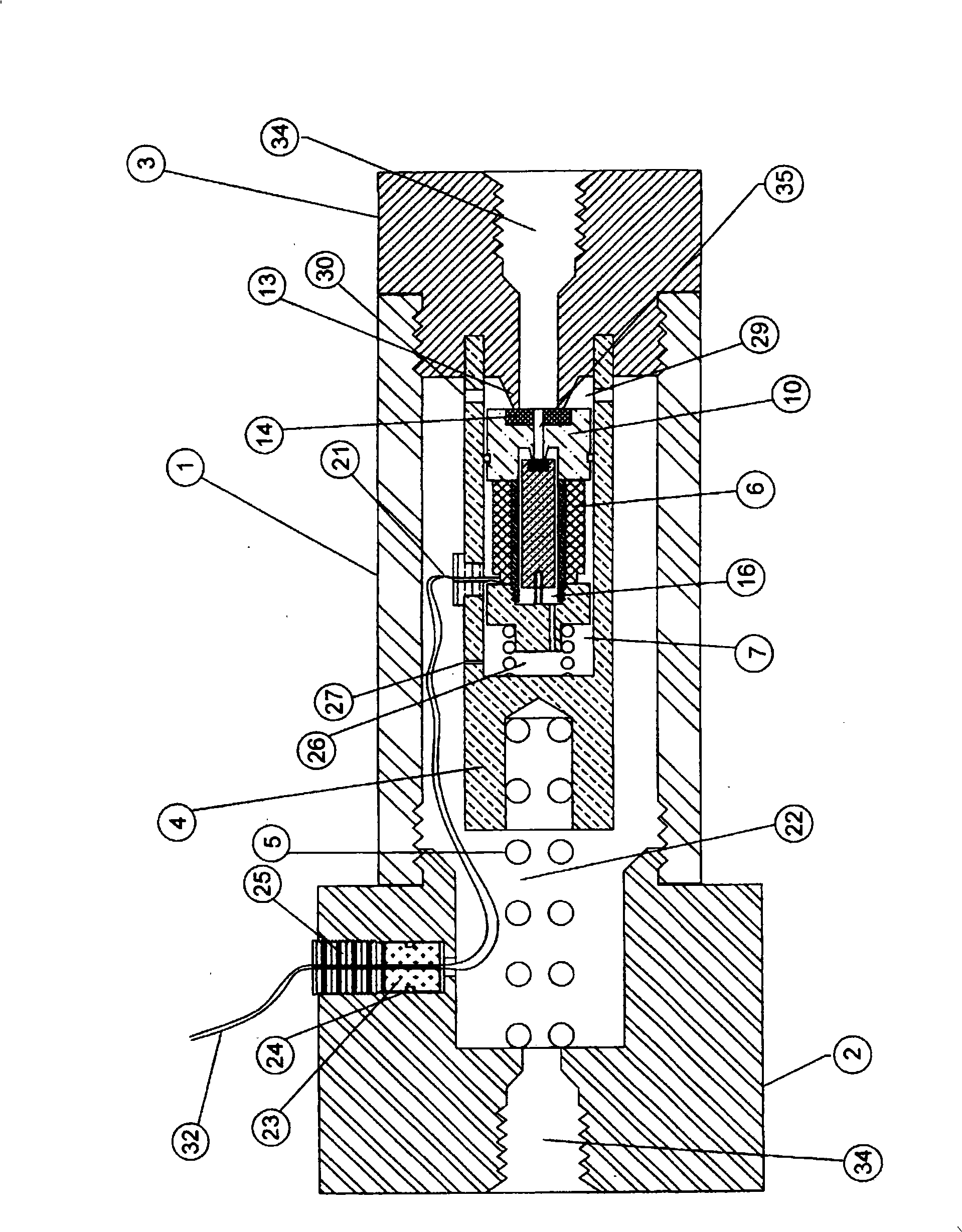

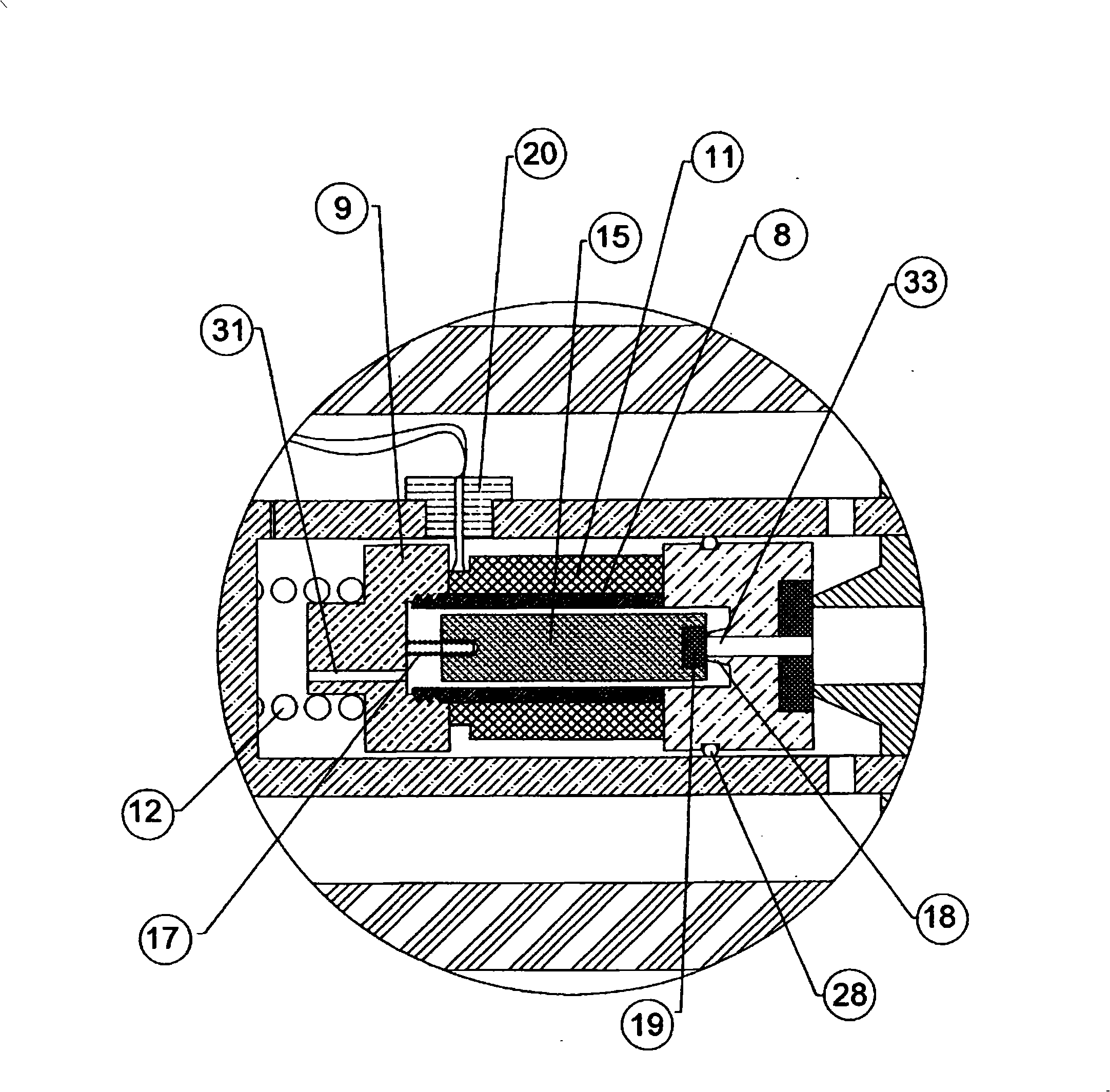

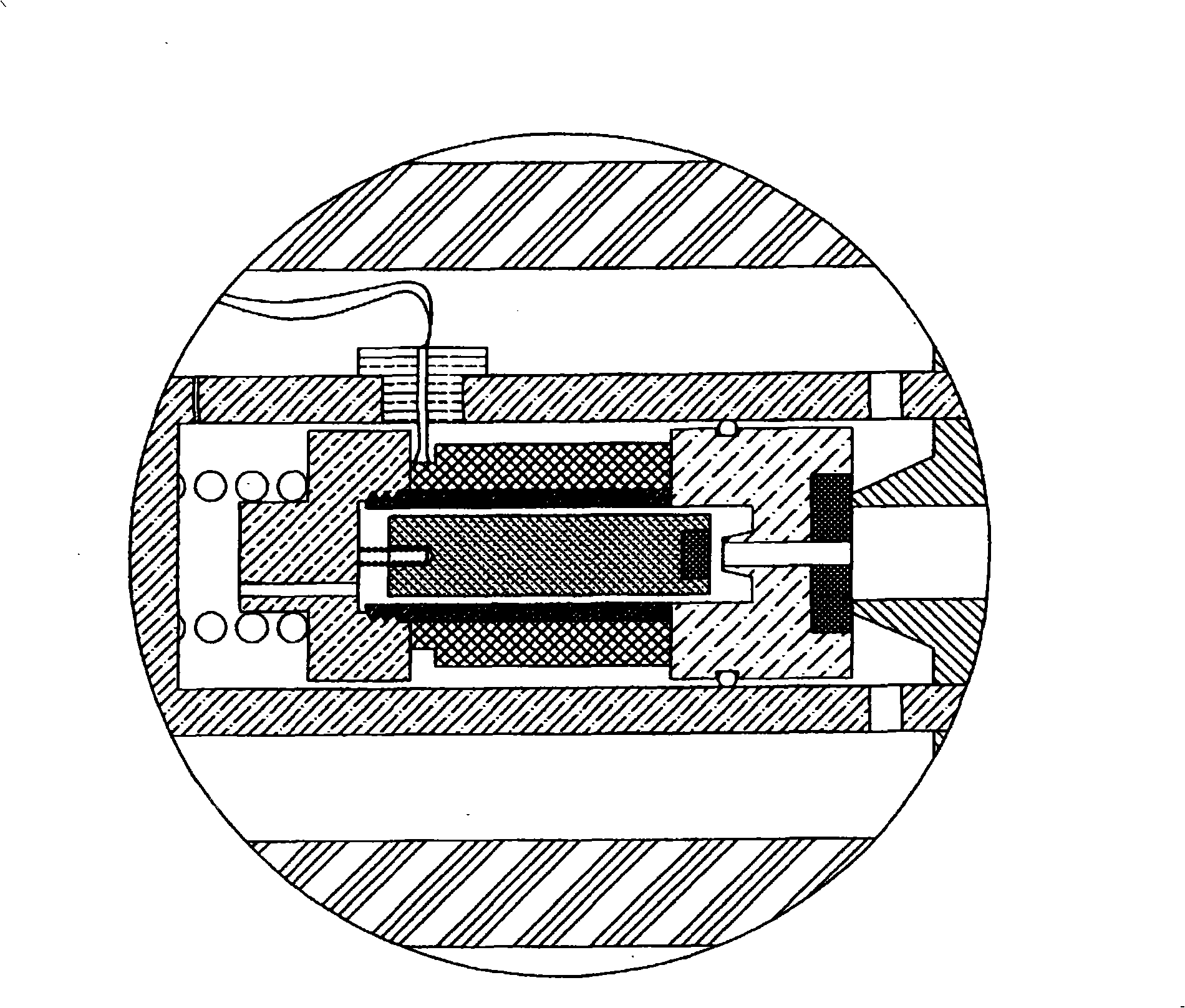

[0023] focus first on figure 1 with figure 2 , which shows a cross-section of a solenoid-in-tube gas valve. The valve tube 1 has a hollow hole with leads at both ends, which can be connected to the inlet configuration 2 and the outlet configuration 3 . Both configurations have corresponding configurations of the central bore 34 with internal leads for connection to the piping system. A supporting cylindrical body 4, pushed towards the aforementioned outlet arrangement 3 by a compression spring 5, has a cavity 7, providing space for the solenoid assembly 6 to move, which includes a hollow bush 8, a baffle 9, a flange 10 and an electrical turn 11.

[0024] In the "sealed" state, a compression spring 12 pushes the aforementioned solenoid assembly 6 towards the sealing seat 13 of the aforementioned outlet arrangement 3 . A plastic insert 14 is molded onto the aforementioned flange 10 to provide a sealing point. When a compression spring 17 pushes the electromagnetic rod 15 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com