Double monocular white light three-dimensional measuring systems calibration method

A calibration method and three-dimensional measurement technology, applied in the direction of measuring device, diagnostic recording/measurement, optical device, etc., can solve the problems of increasing appearance volume and production cost, inconvenient calibration, and unsuitable dual-monocular three-dimensional measurement system

Inactive Publication Date: 2008-11-19

三的部落(上海)科技股份有限公司

View PDF0 Cites 37 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, this method requires the projector to project an additional calibration pattern, which will increase its overall size and production cost for a slide projector

In the paper Accurate calibration for a camera-projector measurement system based on structured light projection (Optics and Lasers in Engineering, 2008, doi: 10.1016 / j. optlaseng. 2007.12. 001), Xiaobo Chen proposed a parameter calibration method for a monocular measuring head using a digital projector, but this method is not suitable for use The dual-monocular three-dimensional measurement system of the slide projector, and this method has high requirements for reference calibration objects, which brings inconvenience to calibration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

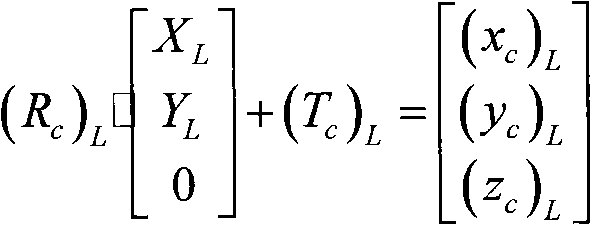

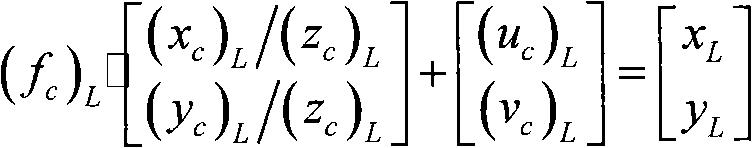

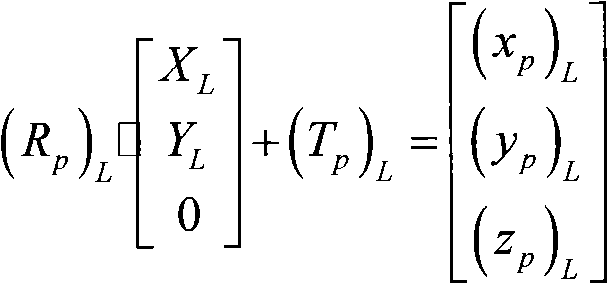

Disclosed is a calibration method for parameters of a double monocular white light three-dimensional measurement system, which belongs to the field of optical measurement and mechanical engineering. The method adopts a plane calibration board as a known calibration object positioned in the measuring range of the system, and obtains the corresponding projection pixel point of a calibration spot in a left camera and the absolute phase value through processing a structured light fringe image on the calibration board projected by a left slide projector and taken by the left camera, and the corresponding projection pixel point of a calibration spot in a right camera and the absolute phase value through processing the structured light fringe image on the calibration board projected by a right slide projector and taken by the right camera. The method goes on linear calibration to a left and a right single measuring head according to the basic data calibrated by the system to obtain as much initial value of parameters of the measurement system as possible and overall nonlinear optimized calibration to the measurement system based on the linear calibration to obtain the optimized value of all the parameters of the measurement system, thereby realizing the precise calibration of parameters of the double monocular white light three-dimensional measurement system.

Description

Calibration method of dual-monocular white light three-dimensional measurement system Technical field: The invention relates to a calibration method for a three-dimensional measurement system, in particular to a calibration method for parameters of a dual-monocular white light three-dimensional measurement system using a slide projector. It belongs to the technical fields of optical measurement and mechanical engineering. Background technique: The traditional camera calibration method is to obtain the calibration basic data by taking a calibration reference object of known size and processing the captured image, so as to realize the calibration of the camera parameters. The basic data of camera calibration establishes the correspondence between the measured coordinate system coordinates of known calibration points and the projected pixel coordinates of calibration points acquired by camera image processing; the traditional calibration method of projectors is to project a c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B11/00G01B11/03G01B11/24A61B5/107

Inventor 习俊通陈晓波熊耀阳张富强

Owner 三的部落(上海)科技股份有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com