Refrigeration cycle apparatus

A refrigeration cycle and control device technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reduced exhaust gas refrigerant, poor exhaust bypass effect, long defrosting time, etc. Road resistance, small flow resistance, and effect of reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, referring to the drawings, an embodiment of the refrigeration cycle apparatus of the present invention will be described by taking the case of being installed in an air conditioner as an example. The present invention is not limited to this embodiment.

[0032] (Embodiment 1)

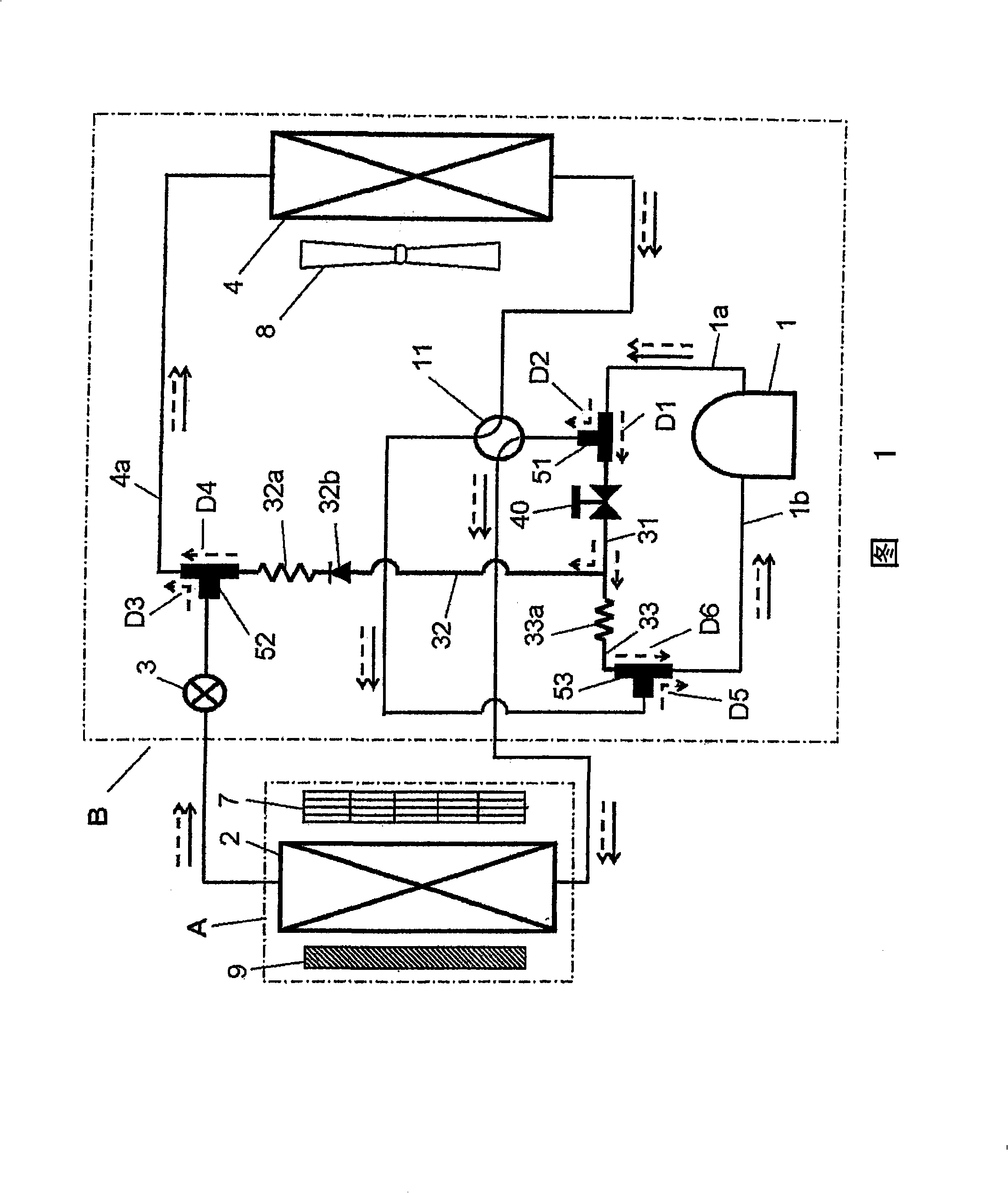

[0033] Fig. 1 is a refrigerant system diagram of a refrigeration cycle device according to Embodiment 1 of the present invention, showing the refrigerant flow of an air conditioner (in the direction of solid arrows during heating operation, and in the direction of dotted arrows in defrosting operation). In Fig. 1, compressor 1 for compressing refrigerant, four-way valve 11 for changing refrigerant flow, condenser 2 for condensing high-pressure and high-temperature refrigerant, throttling device 3 for decompressing condensed refrigerant, The evaporators 4 for evaporating the depressurized refrigerant are connected sequentially through piping to constitute a normal refrigeration cycle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com