Copper tube connection device and method

A connection device, copper pipe technology, applied in non-detachable pipe connections, pipes/pipe joints/fittings, piping systems, etc., can solve problems such as capillary blockage, refrigerant leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

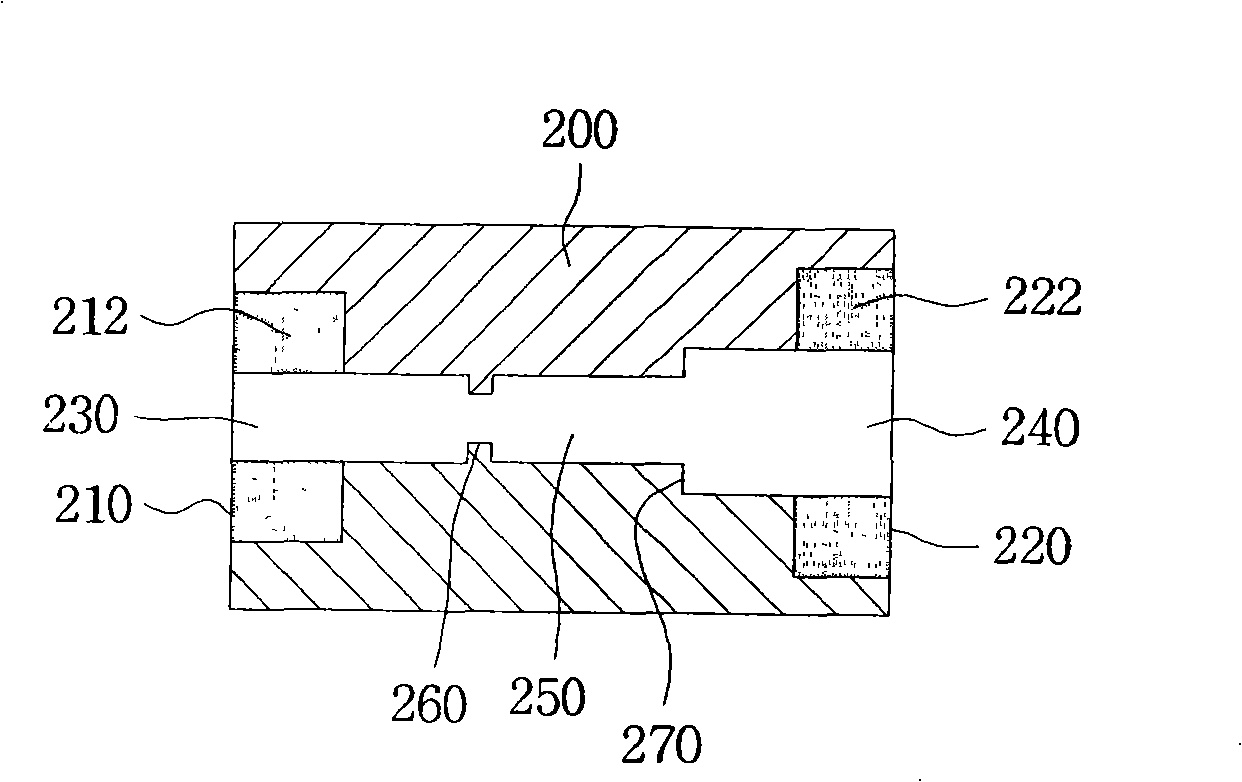

[0033] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings. In the following description and drawings, the same symbols are used to indicate the same or similar components, so repeated descriptions about the same or similar components will not be repeated here.

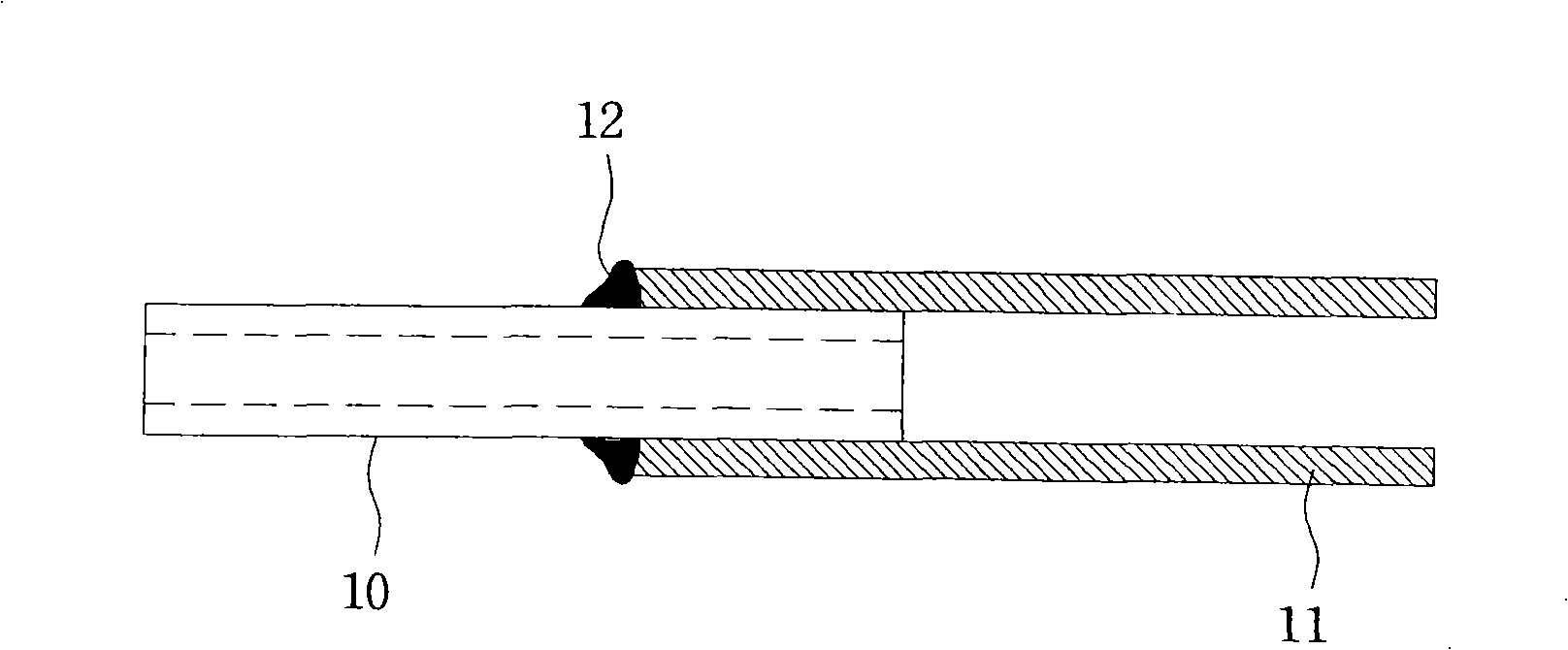

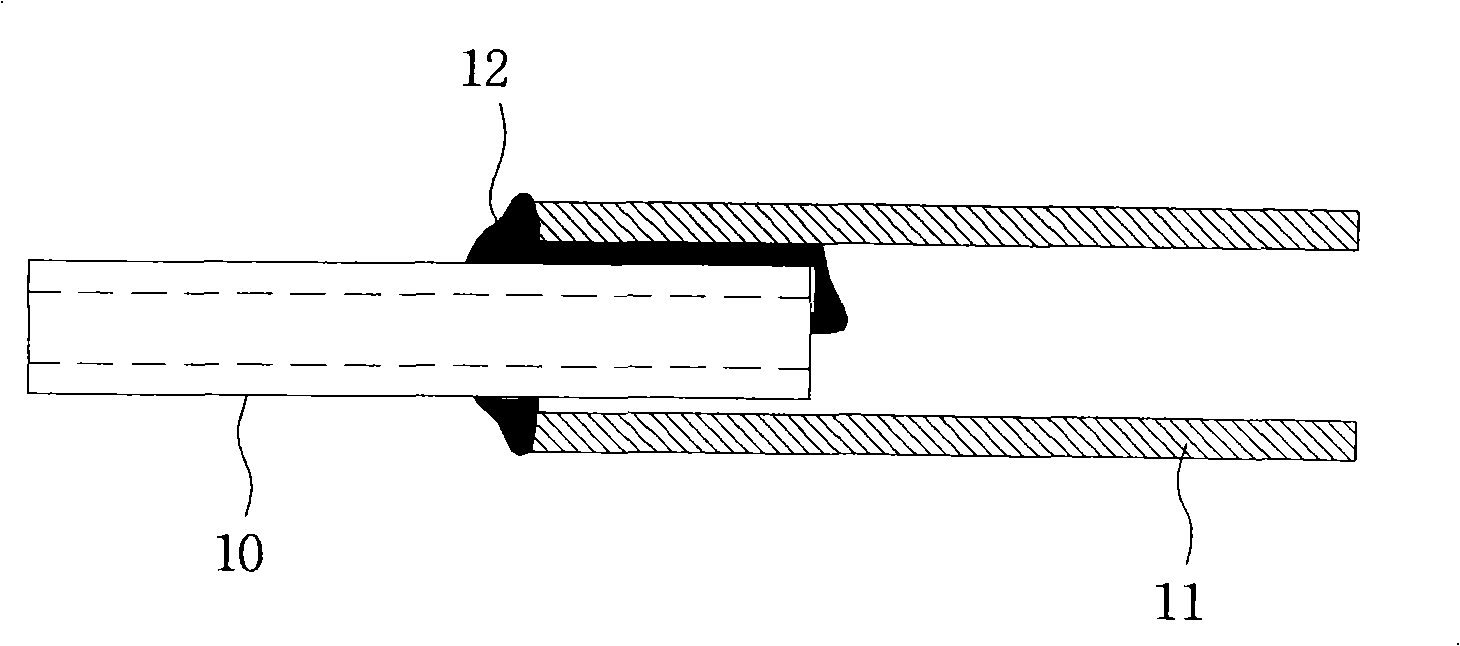

[0034] figure 2 is a schematic structural view of the copper pipe connection device according to the first embodiment of the present invention; image 3 is a schematic diagram of the principle of use of the copper pipe connecting device according to the first embodiment of the present invention.

[0035] refer to figure 2 , the copper tube connection device comprises a hollow body 200 with a hollow portion, so that the copper tube can be inserted into the hollow body; a copper tube insertion hole 230 processed on the first end of the body 200, the first diameter of which corresponds to the copper tube The diameter of the pipe 100; a second pipe inserti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com