Process for producing fuel ethanol by stalk beating method

A technology of fuel ethanol and straw, applied in the direction of biofuels, microorganisms, methods based on microorganisms, etc., can solve the problems of raw material freshness preservation, difficulty in handling large-scale production tasks, difficult problems, etc., to achieve uniform mixing, Effect of shortening fermentation time and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

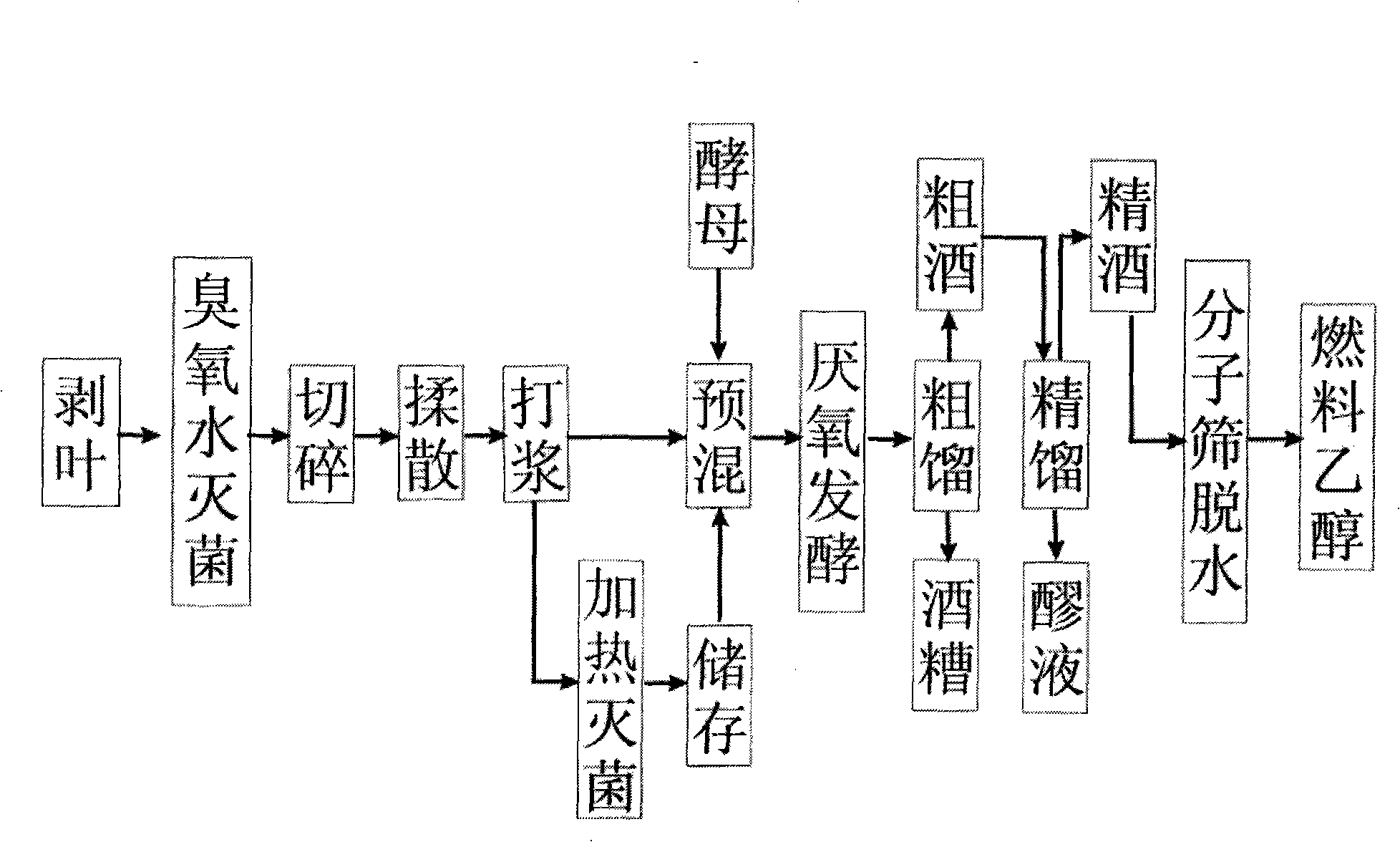

[0048] Using straw as raw material figure 1 The production process of fuel ethanol by beating method is shown for the production of fuel ethanol: fresh straw cleaning—cleaning—ozone sterilization—chopping—kneading—beating—(preservation)—adding yeast—preparation Mixing - anaerobic fermentation - rough distillation - rectification - dehydration and other links. The process includes the following ten procedures:

[0049] ①Clean the straw and remove the leaves. The leaves of sweet sorghum are removed by a leaf stripper, and then the straw is stacked neatly.

[0050] ②Use a crane to load the straw into the drum washing machine and wash it for 20 minutes.

[0051] ③ Pour the cleaned straw into the disinfection tank, and sterilize it by soaking in ozone water with a concentration of 100 mg / ton for 20 minutes.

[0052] ④ Use a four-roller knife grass cutter to cut the straw into 8 to 12mm pieces.

[0053] ⑤The broken pieces of straw are sent to the kneading machine to be kneaded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com