Probe unit and detection apparatus

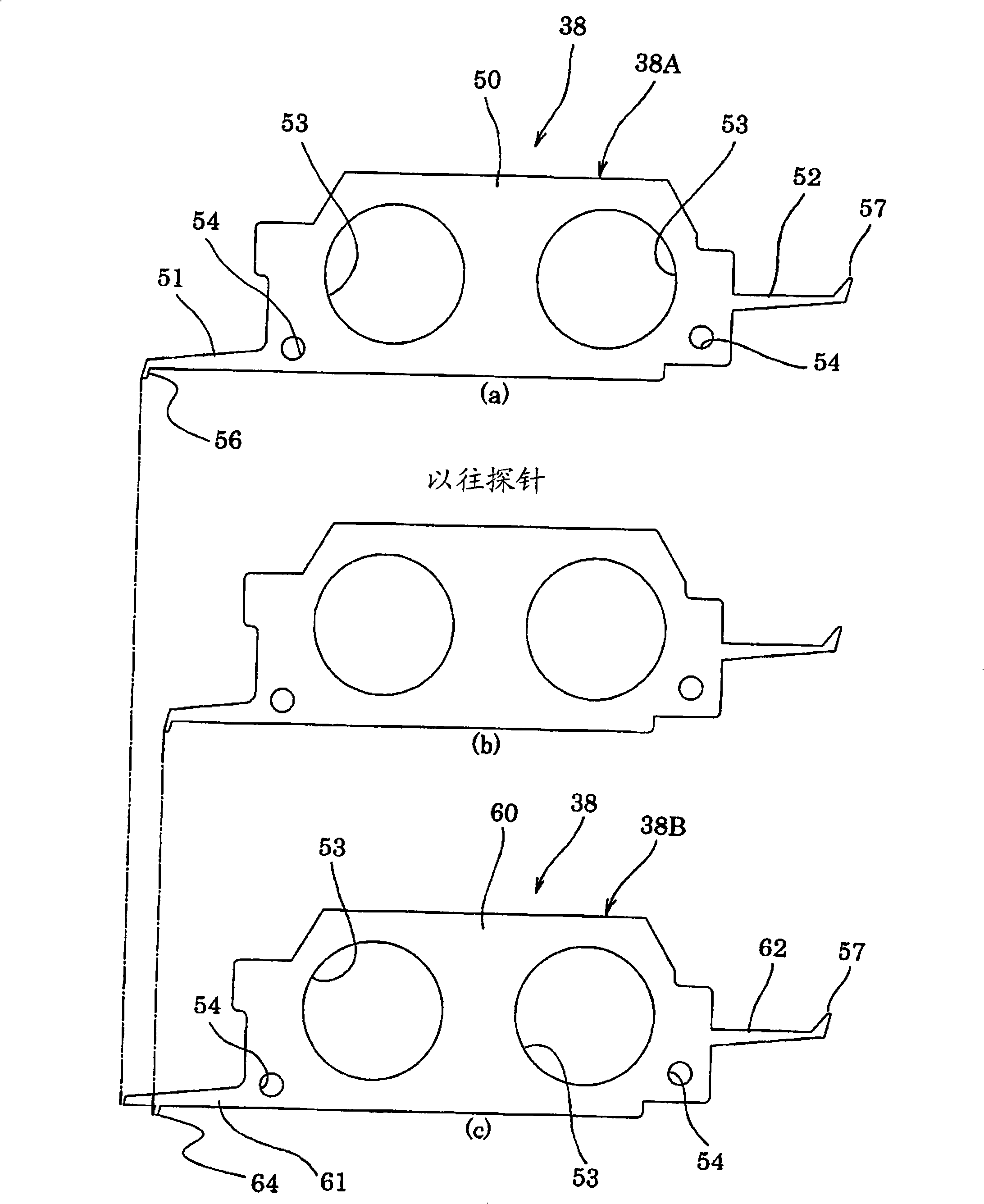

A technology of probe unit and inspection device, applied in the direction of measuring device, thin plate connection, manufacturing measuring instrument, etc., can solve the problems of not easy, twisted and damaged blade-type probes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

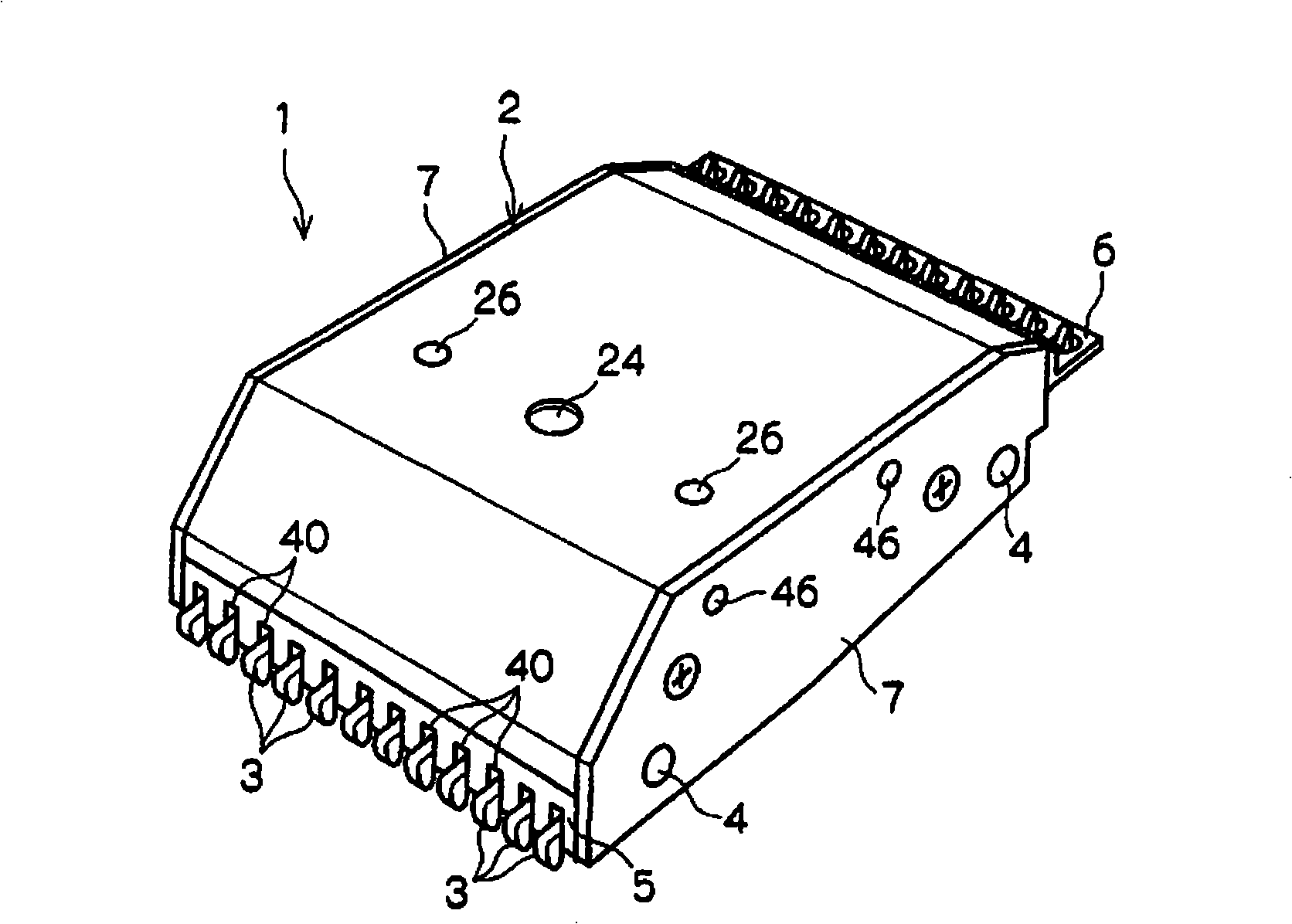

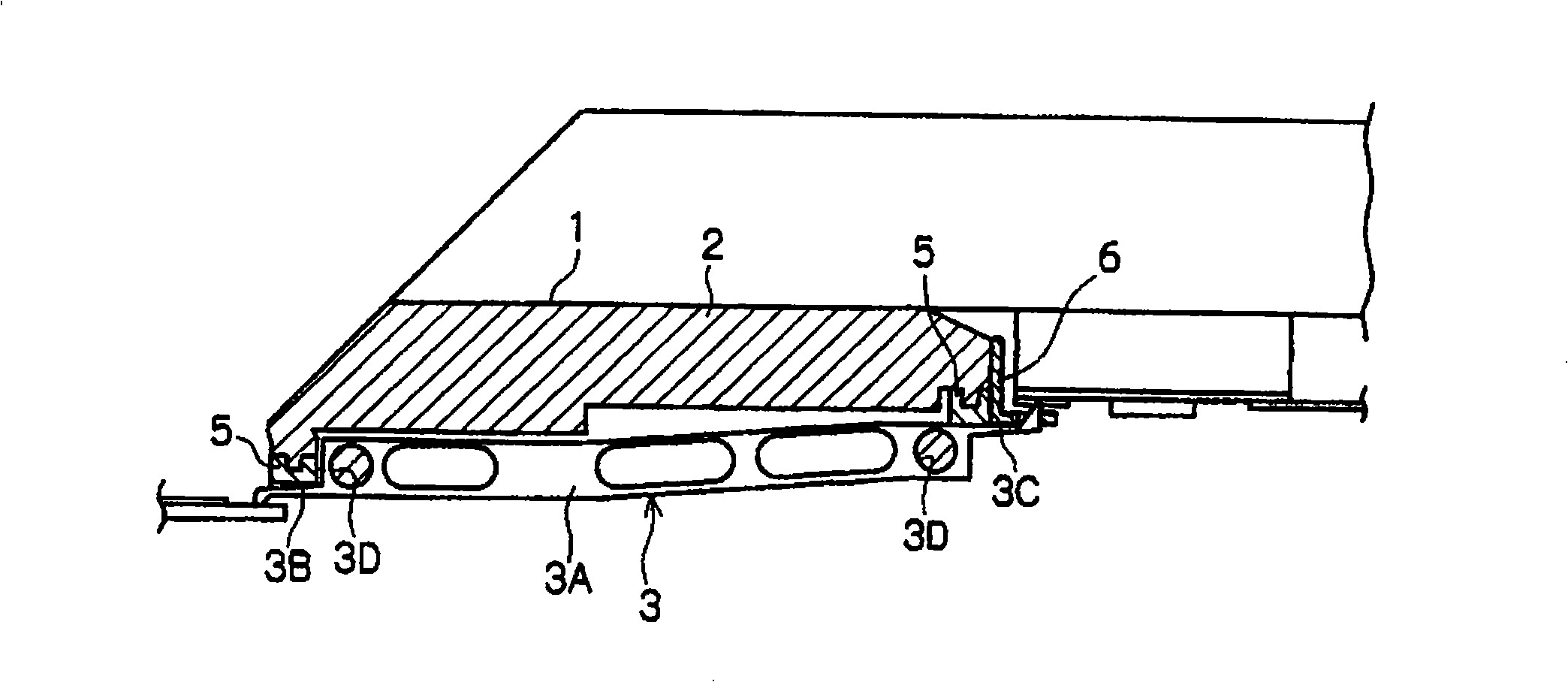

[0025] Hereinafter, a probe unit and an inspection device according to an embodiment of the present invention will be described with reference to the drawings. The inspection device of this embodiment is used to inspect the object to be inspected, and has a set part for carrying the object to be inspected from the outside and carrying the object to be inspected outside after the inspection is completed, and a set for supporting the object to be inspected from the setting part. Assay department that examines bodies and performs tests on them. The probe unit of the present embodiment is used for the probe unit of the measurement unit of the inspection device. In addition, since the inspection apparatus of this embodiment is substantially the same as the above-mentioned conventional inspection apparatus, the probe unit is mainly demonstrated here. In addition, the inspection device of the present invention can be applied to all devices that can use the probe unit of this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com