Absorption type ice making machine using marine vehicle diesel residual heat

A technology for marine diesel engines and diesel engines, which is applied in the directions of ice making, ice making, and application, can solve the problems of increased operating costs, large ice demand, waste of energy, etc., and achieves the effect of reducing ice making costs and improving energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

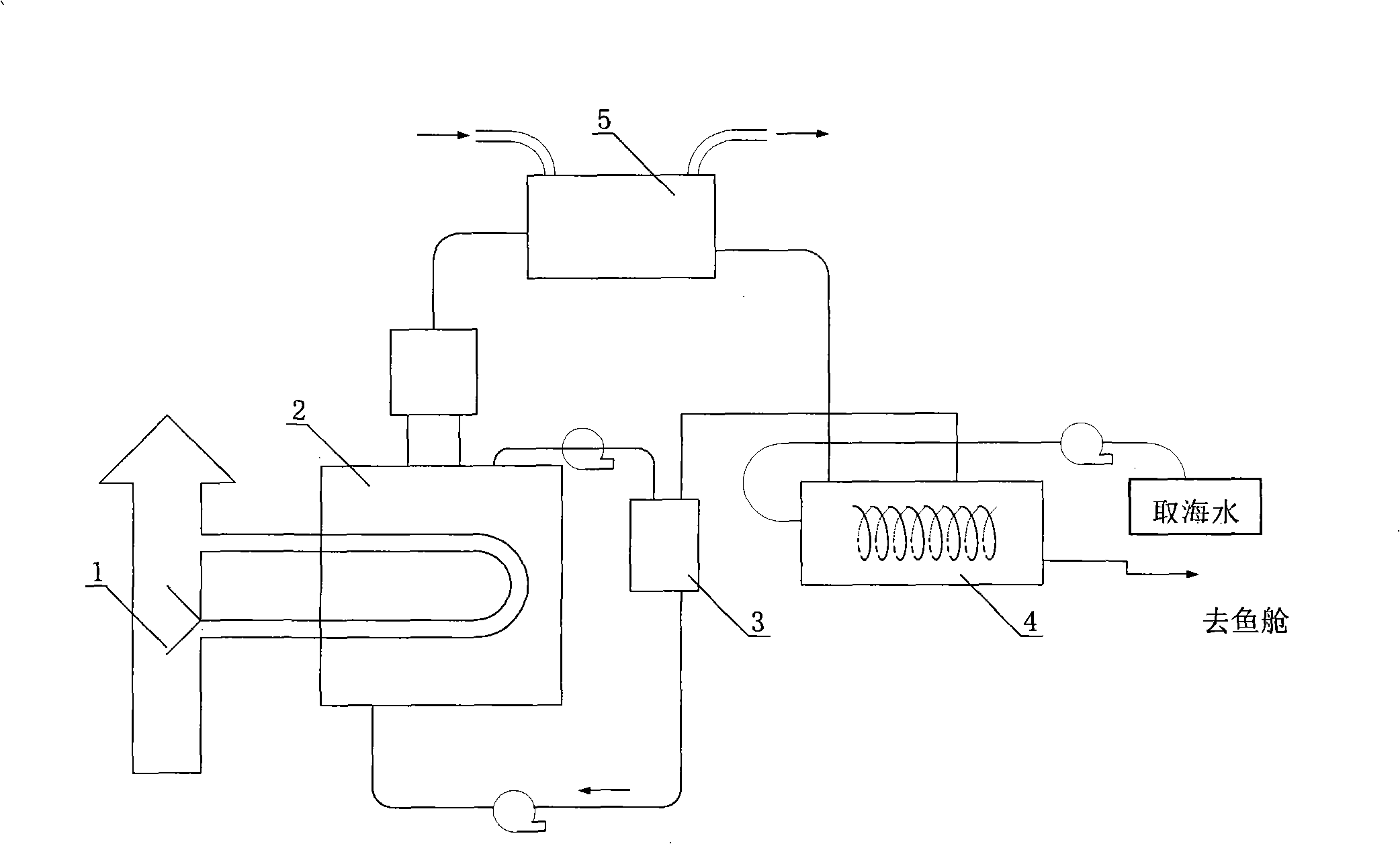

[0009] Referring to the accompanying drawings, the present invention uses the exhaust gas of a marine diesel engine as a driving heat source and uses TFE / NMP as a pair of working fluids for an ice maker. It is mainly composed of a diesel engine exhaust converter 1, a flue gas regenerator 2, an absorber 3, an evaporator with an ice maker 4, and a condenser 5. The flue gas regenerator 2 is connected to the absorber 3 and the condenser 5 respectively, the absorber 3 is connected to the evaporator 4 with an ice maker, and the diesel engine smoke exhaust converter 1 is connected to the marine diesel engine chimney or exhaust pipe, The trifluoroethanol / N-methylpyrrolidone working medium pair is used, which has low working pressure, high COP value and good thermochemical stability. Seawater is used as the ice source, and the internal ice maker is in a spiral motion. While making ice, the binary ice is sent out of the fish cabin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com