DC giant wheel hydroturbine

A Ferris wheel and water turbine technology, applied in water wheel, tidal flow/damless hydropower, mechanical equipment, etc., can solve problems such as low power generation head, not reaching the stage of large-scale commercial development, and deep excavation of machine pits. The effect of cost reduction in kilowatts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

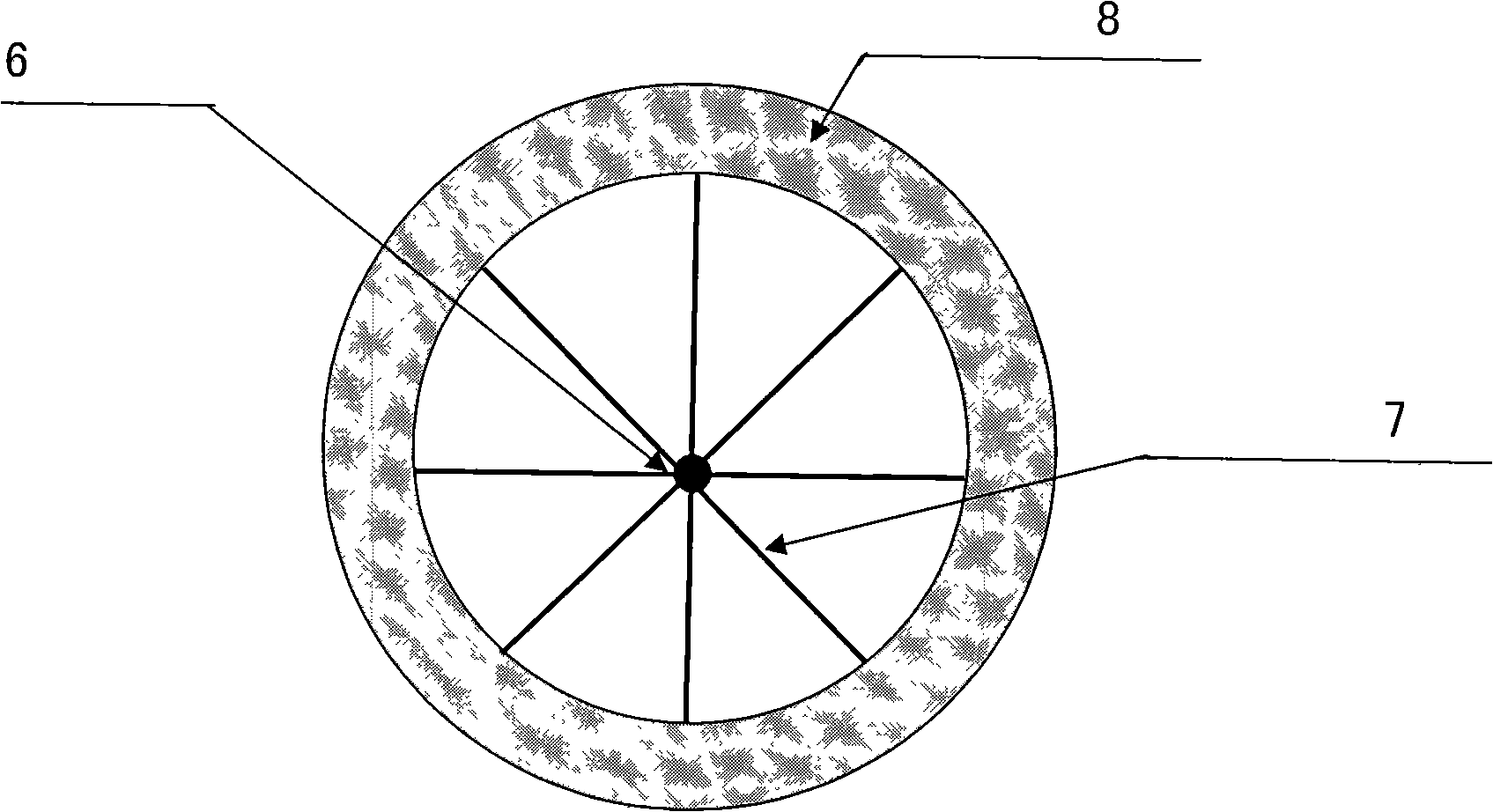

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the present invention mainly consists of a water turbine (1), a speed increaser (2) and a generator (3) to form a generating set, and the water turbine (1) axle (4) is supported on the water turbine support. The water turbine of the present invention is mainly composed of a wheel shaft (6), a steel wheel frame (7) and a semi-closed wheel blade (8). The speed increaser (2) of the present invention is an intermeshing gear speed increase mechanism or a belt pulley transmission speed increase mechanism; the speed increaser (2) is two types of drive wheel transmission configuration or drive shaft transmission configuration. The structure of the speed increaser is a conventional technology, so like the generator described in the present invention, it belongs to the conventional technology mastered by those skilled in the art.

[0014] The ferris wheel wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com