Barrel roll laundry machine wide band elastic granule damper

A particle damper and elastic particle technology, which is applied in other washing machines, springs/shock absorbers, shock absorbers, etc., can solve the problems of cost sensitivity, high processing cost, and high metal rigidity, so as to reduce jumping or wandering, The effect of strong installation adaptability and applicable frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

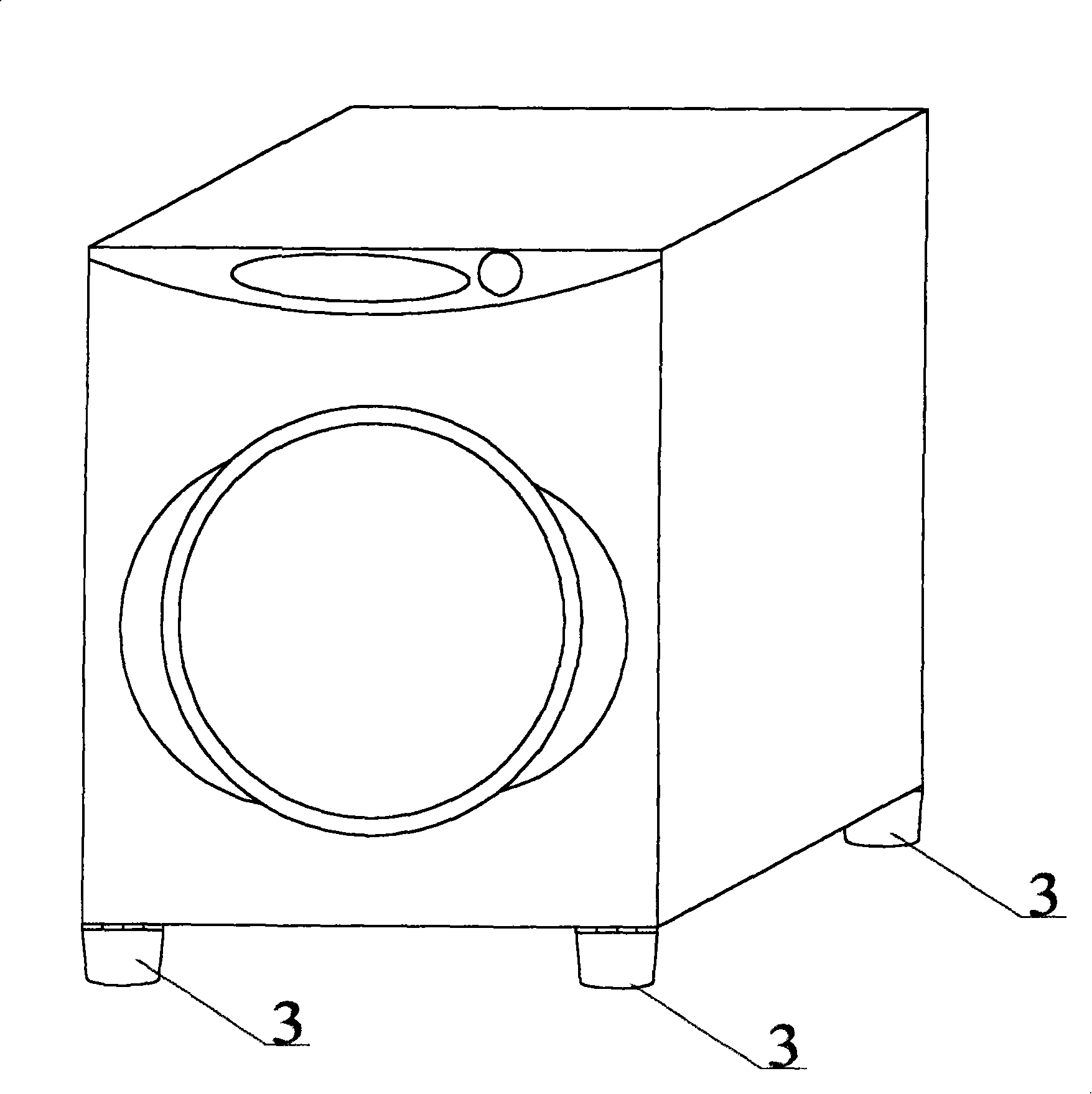

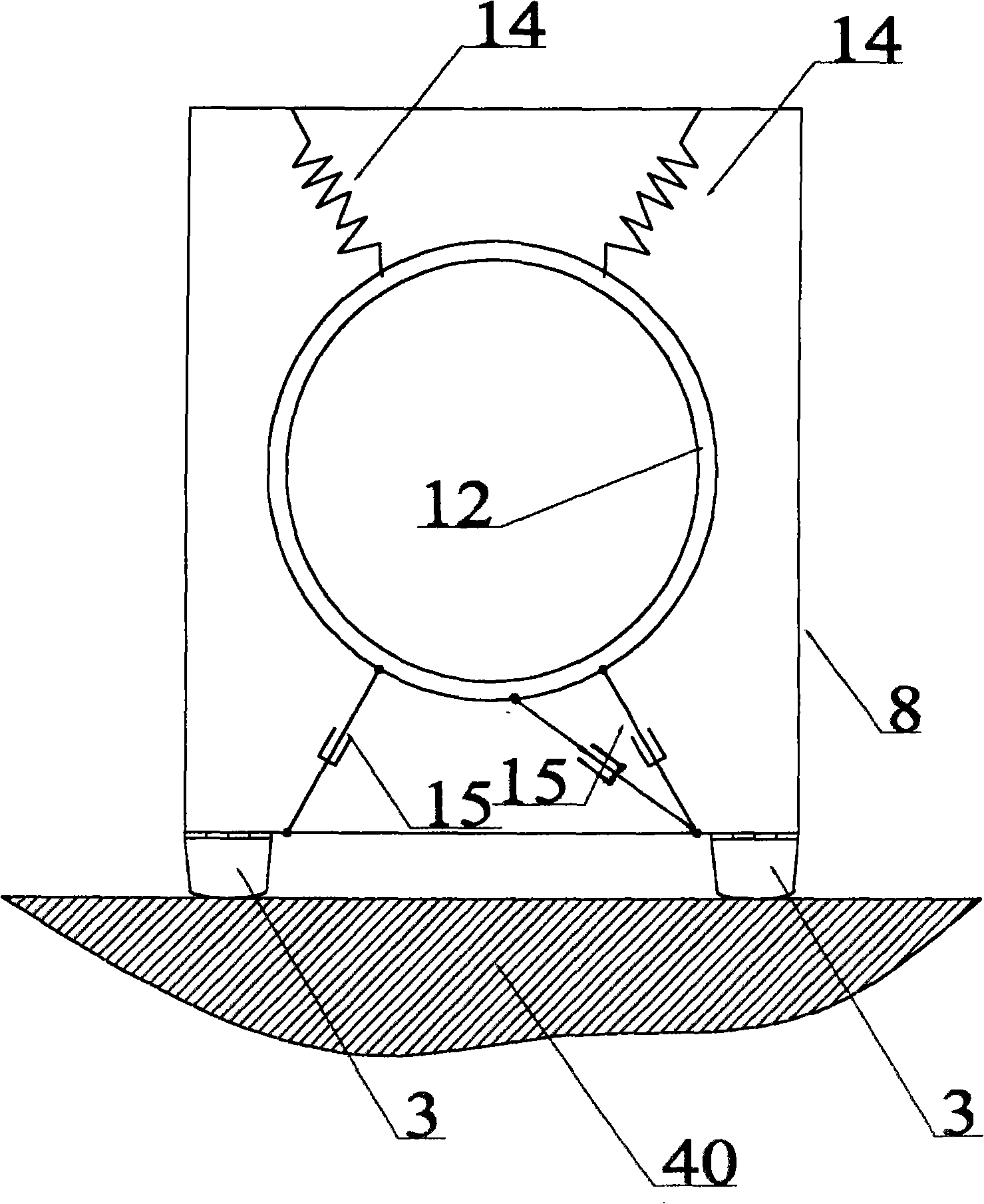

[0085] Will Figure 8 The shown broadband elastic particle damper for a drum washing machine is applied to a drum washing machine to replace traditional foot pads:

[0086] 1) The elastic housing 86 is made of metal material, and the rigidity of the elastic vibration isolator is about 100Kgf / mm of rubber-plastic elastic material; the particles are surface-treated iron powder with irregular shape; the iron powder The particle size range is 0.0001 microns to 1 mm; the filling level is 80%;

[0087] 2) wherein the elastic housing 86 is made of metal material, and the rigidity of the elastic vibration isolator is about 200Kgf / mm rubber-plastic elastic material; the particles are surface-treated iron powder with irregular morphology; the iron powder The particle size range is 1 micron to 0.5 mm; the filling level is 100%;

[0088] 3) wherein the elastic housing 86 is made of metal material, and the rigidity of the elastic vibration isolator is about 150Kgf / mm rubber-plastic elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com