Device and method for testing filtration efficiency of biologic aerosol for filtering or separating material

A bio-aerosol and filtration efficiency technology, applied in the field of air purification and bio-cleaning technology, can solve the problems of immobility, inability to meet, difficult to move, etc., to achieve the effect of short interval time, ensure accuracy, and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

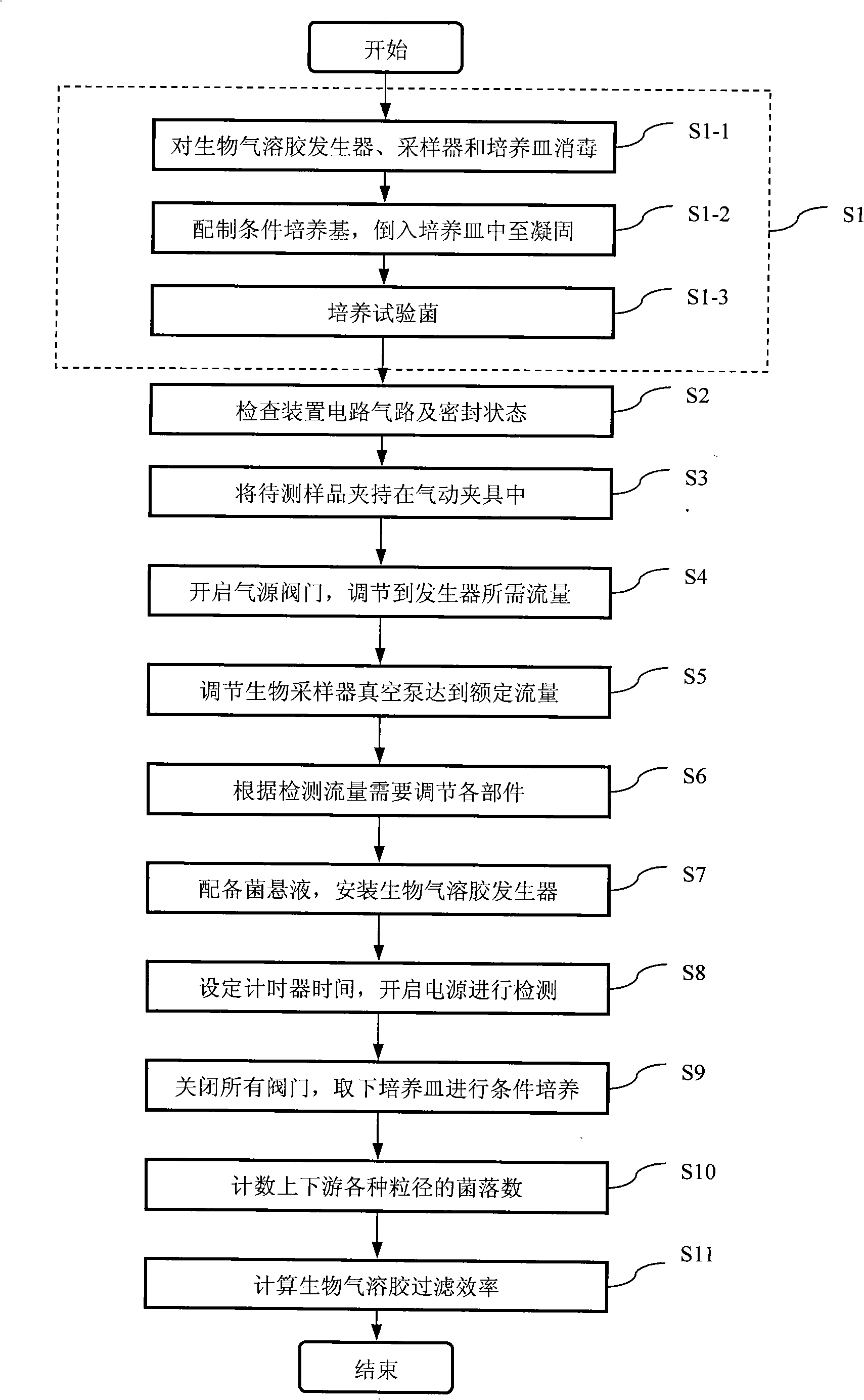

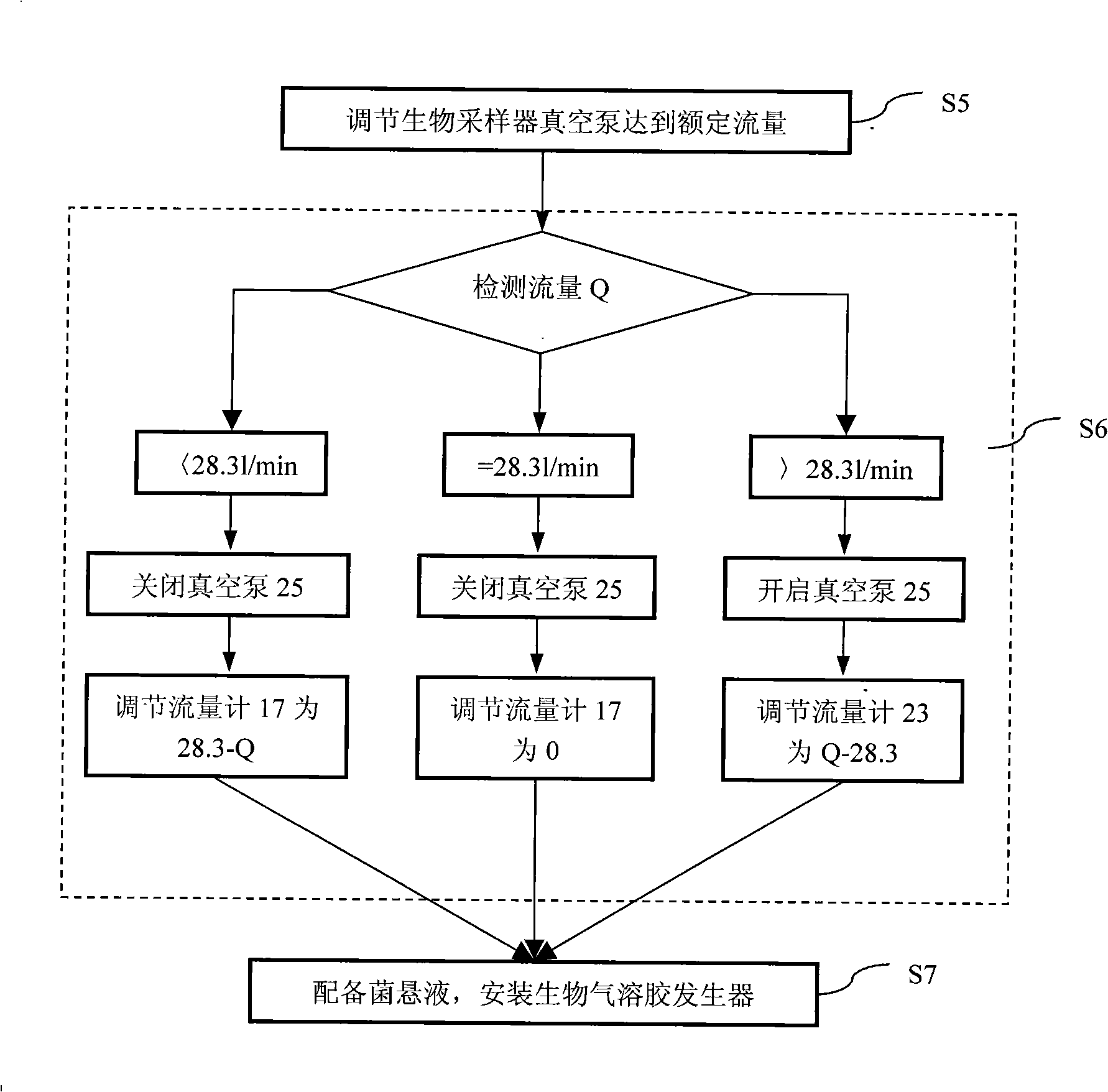

Method used

Image

Examples

Embodiment 1

[0044] The detection flow rate is 28.31 / min, the sampler is a six-stage impact Anderson sampler, the upstream sampling time is set to 30s, and the downstream sampling time is set to 5min, and a high-efficiency glass fiber filter paper is used as a sample to carry out four repeated detection experiments of bacteria filtration efficiency. As shown in the table below, the conditions used in this embodiment determine that the highest detection efficiency is 99.99%, and the value greater than this value is represented by ">99.99%".

[0045] Particle size range

Embodiment 2

[0047] The detection flow rate is 20, 28.3 and 401 / min, the sampler is a six-stage impact Anderson sampler, the upstream sampling time is set to 30s, and the downstream sampling time is set to 5min. An N95 mask is used as a sample for three tests. The results are shown in the table below. The conditions used in this embodiment determine that the highest detection efficiency is 99.99%, and those greater than this value are represented by ">99.99%".

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com