Hook tile kiln discharge conveying method and device

A conveying device and conveying rack technology, which is applied in the directions of transportation and packaging, packaging, and processing of discharged materials, can solve the problems of difficulty in the production of hook tiles, failure of conveyor belts, damage to tiles, etc., and achieves light weight, reasonable structure, and avoidance of glitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

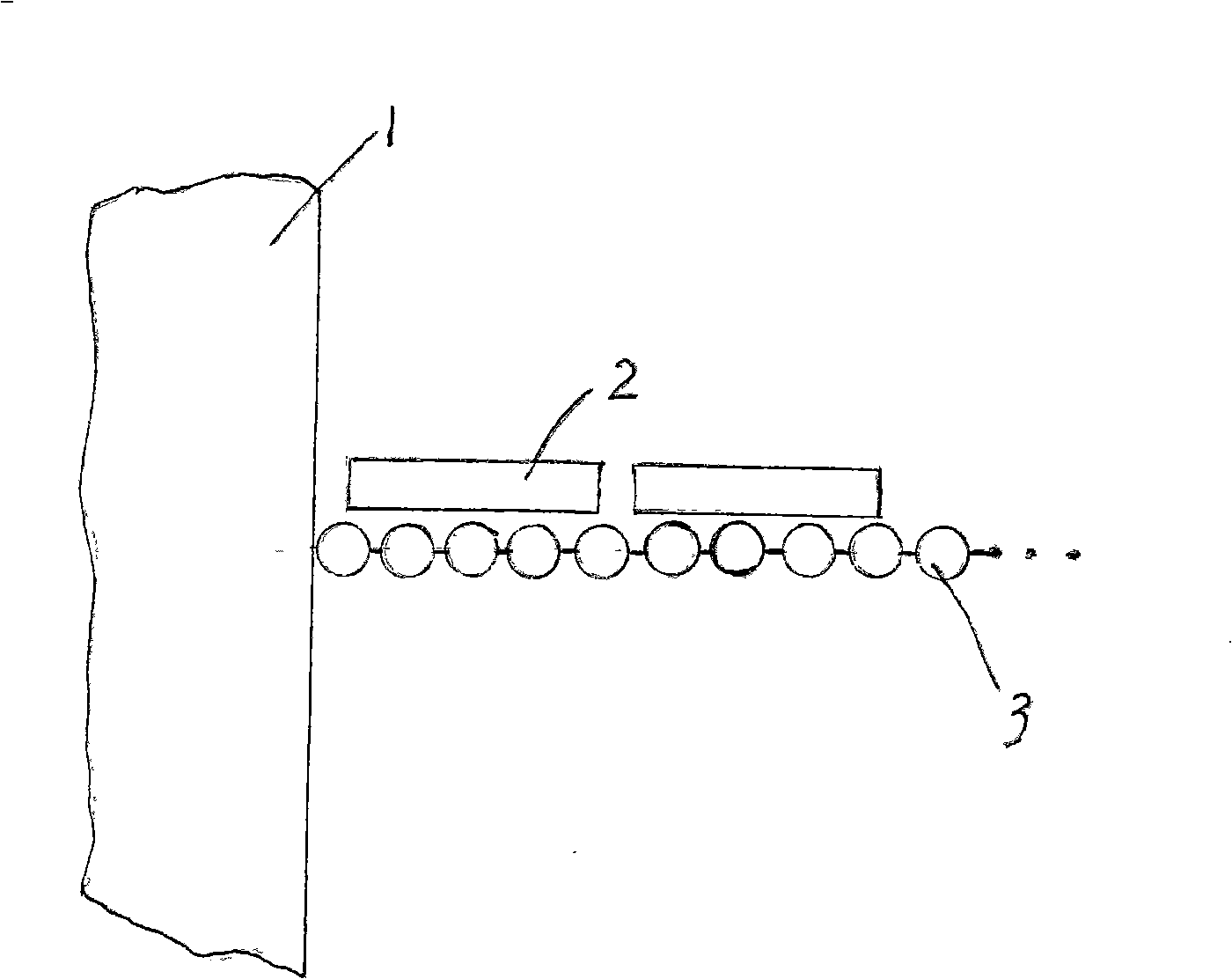

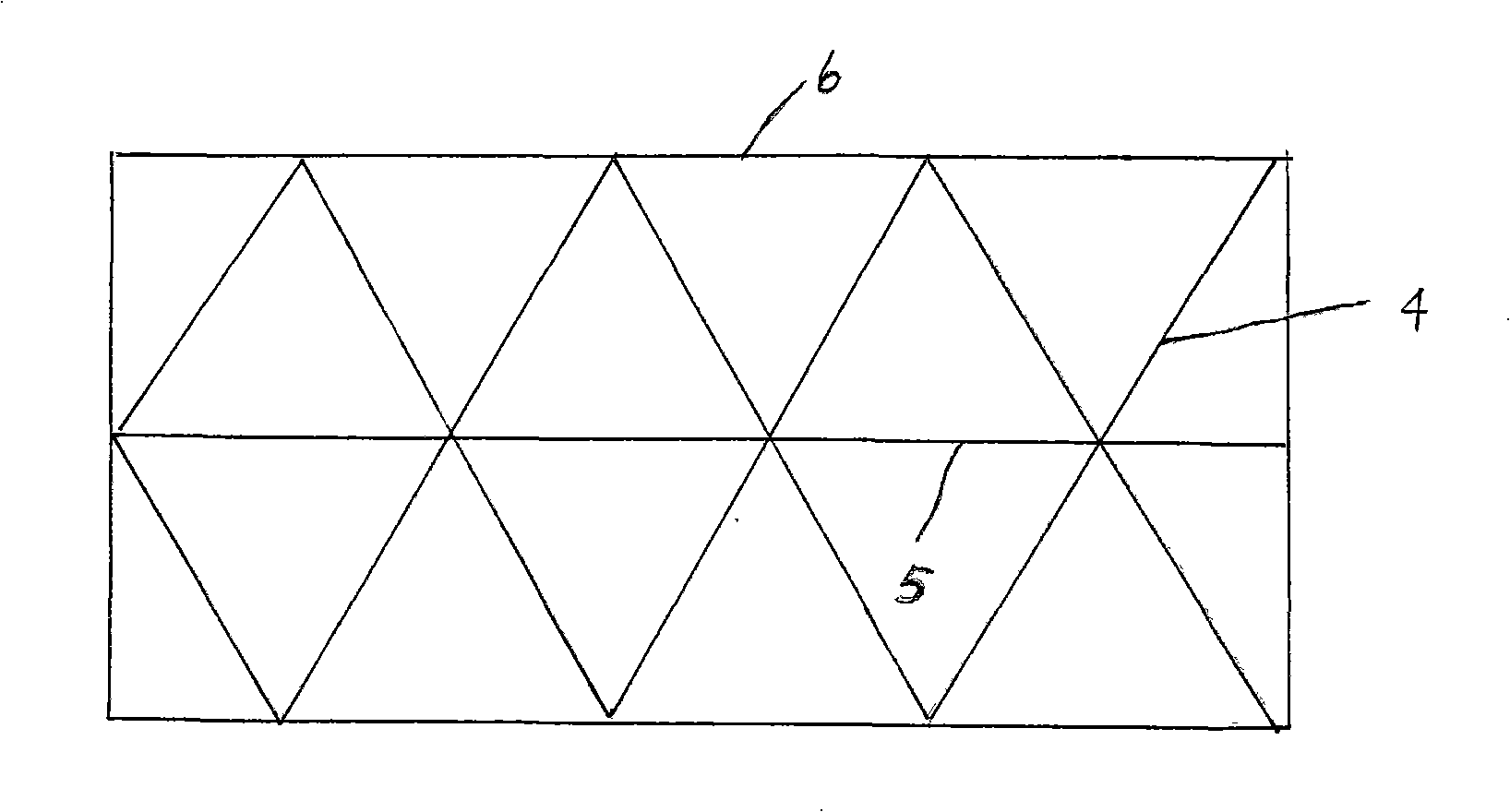

[0010] On the roller 3 of the outlet conveying device of existing hook tile burning kiln 1, a plurality of hook tile conveying frames 2 are set. Generally, 1 to 3 are used. The structure of each flat-hanging tile conveying frame is: the surrounding is a closed frame 6 with ribs in the middle, such as figure 1 As shown, the distribution of the ribs in the middle is: there is a strip-shaped rib 5 parallel to the frame in the middle of the closed frame, and there are symmetrical triangular ribs 4 on both sides divided by the rib. Other geometries that provide structural strength may also be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com