Method for eliminating tooth space by means of stabilized platform double-direct current torch motor micro-differential drive

A technology of DC torque motor and stable platform, which is applied to components with teeth, mechanical equipment, transmission parts, etc., and can solve problems such as wear, impact of mechanical parts, out-of-step, overshoot and oscillation, and manufacturing errors of transmission gears. Achieve the effect of improving positioning accuracy, easy to implement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

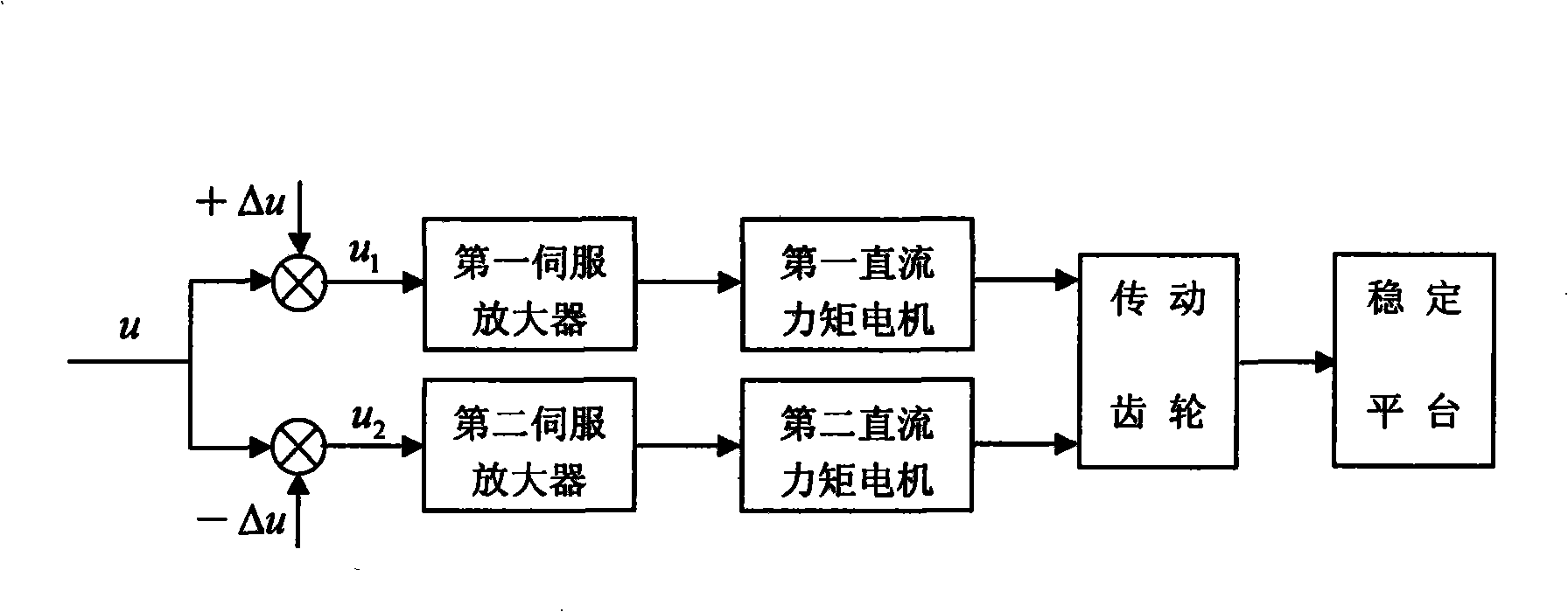

[0007] The specific embodiment of the present invention is as figure 1 As shown, let the control amount of the first DC torque motor be u 1 , the control amount of the second DC torque motor is u 2 , the differential amount Δu is the minimum control amount that can overcome the static friction of the transmission mechanism when the two motors independently drive the stable platform, take u 1 =u+Δu,u 2 =u-Δu, the control value u of the first DC torque motor 1 and the control variable u of the second DC torque motor 2 After passing through the first servo amplifier and the second servo amplifier, respectively, drive their respective DC torque motors. When |u|≥|Δu|, the first and second two DC torque motors drive the transmission gear in the same direction, and when |u|<|Δu|, the first and second two DC torque motors form a reverse drive The transmission gear, in which the DC torque motor with a large absolute value of the control amount plays a leading role in driving the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com