Wooden plate equal width sorting machine

A material selecting machine and wood board technology, applied in the field of woodworking machinery, can solve the problems of unsuitable product quality assurance, low board grading accuracy, difficult board splicing, etc., and achieve the effects of material saving, simple structure and accurate material selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

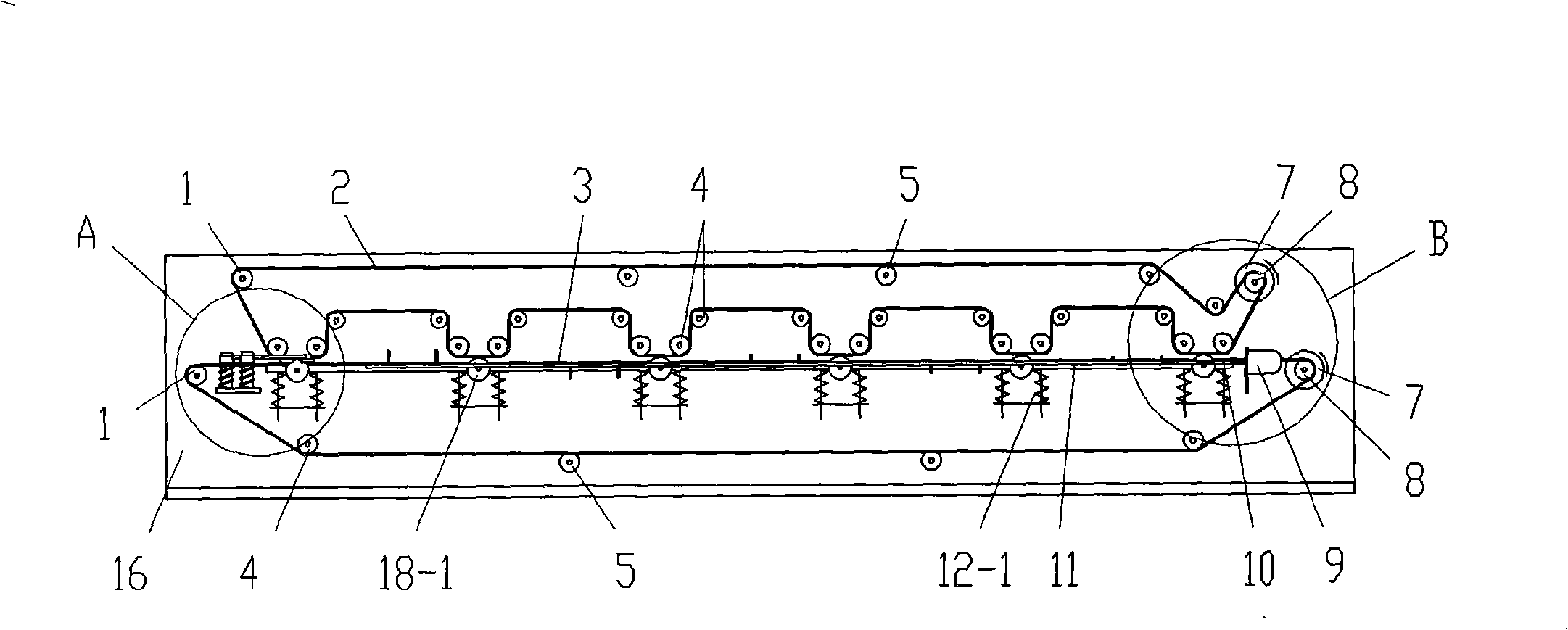

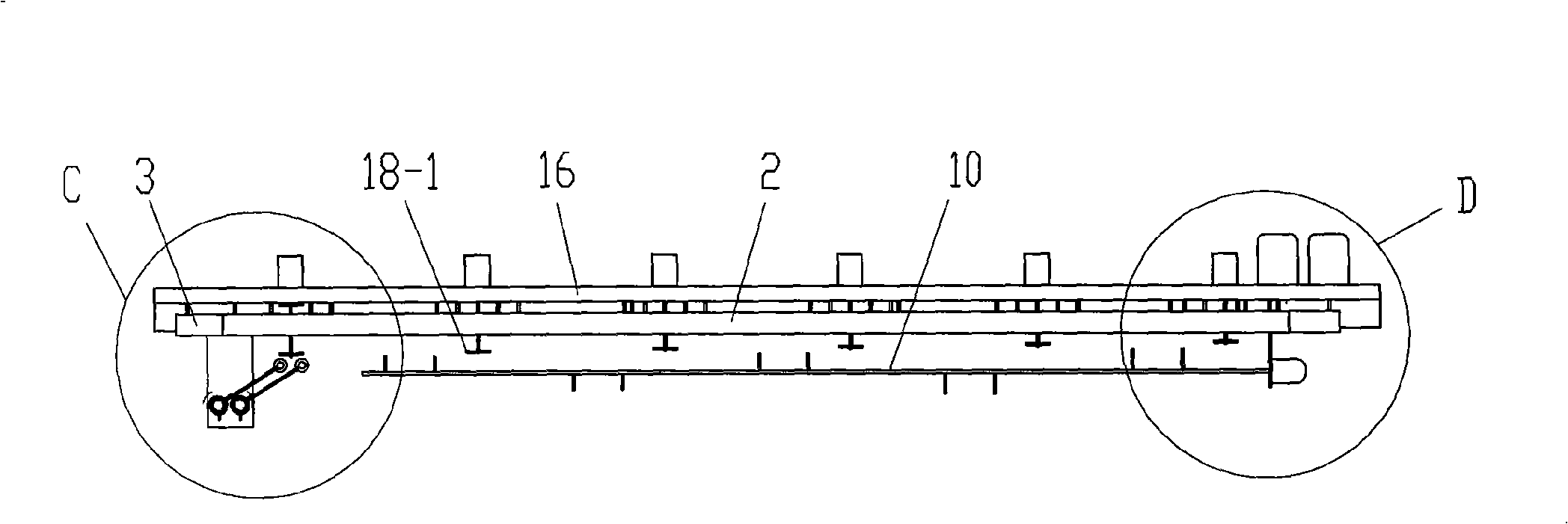

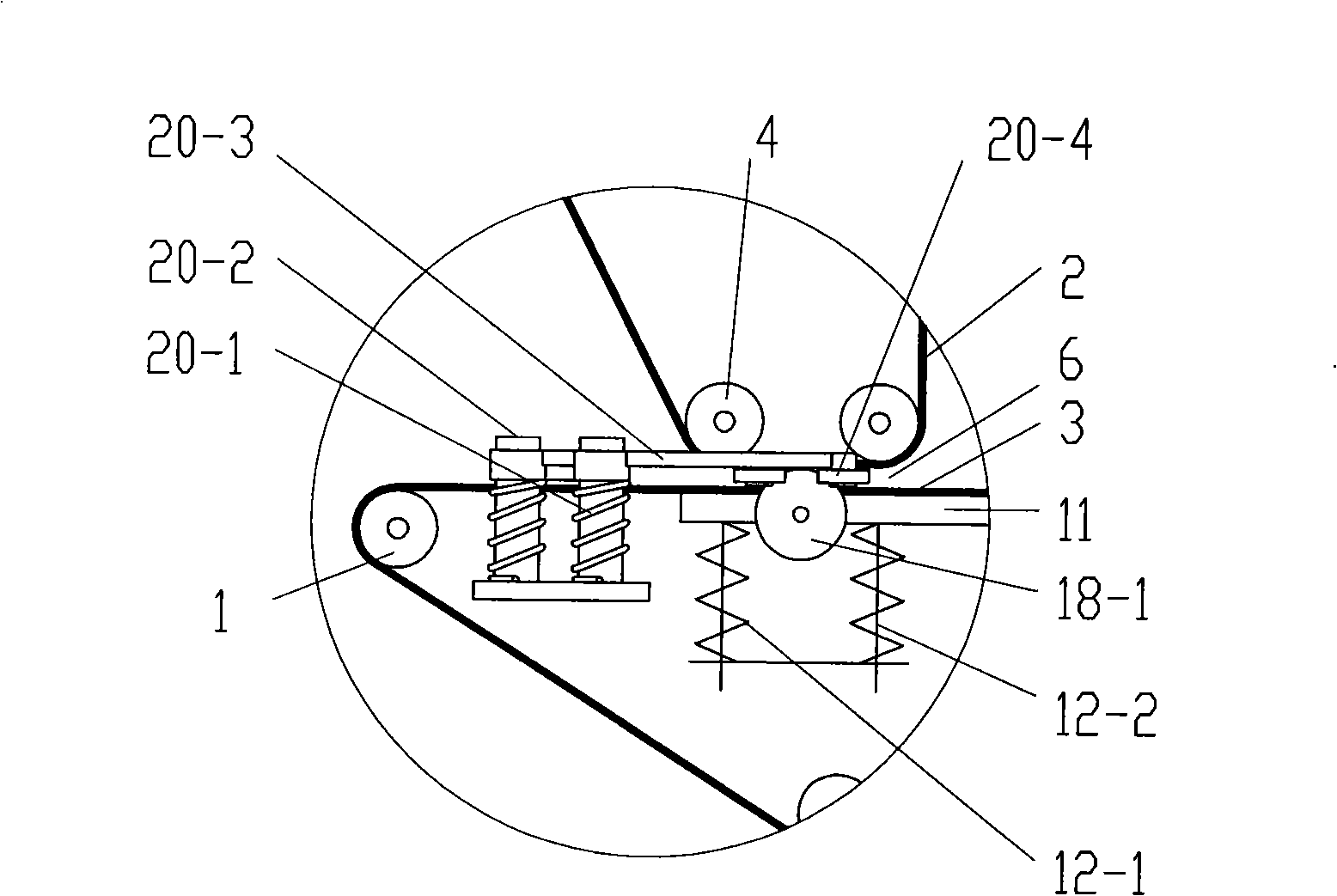

[0022] Such as figure 1 , 2 , 3, shown in 4, the implementation structure of the present invention comprises, frame 16, is provided with two and is respectively made up of motor 7, chain, head wheel 8, tail wheel 1, reversing wheel 4, supporting wheel 5 on frame 16 Chain mechanism, the chains of the two chain mechanisms are vertically arranged ring chains, the ring chains of the two chain mechanisms are arranged up and down, the upper chain of the chain ring of the lower ring chain 3 is arranged along the longitudinal straight line of the frame, and the chain of the upper ring chain 2 The chain on the lower side of the ring is crenellated, and the segments are close to or far away from the chain on the upper side of the chain of the lower chain 3, and the chain on the lower side of the chain of the upper chain 2 and the chain on the upper side of the chain of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com