Control device of work machine

A technology for control devices and working machines, applied in hoisting devices, mechanical equipment, fluid pressure actuating devices, etc., can solve energy loss, deterioration of fuel consumption rate, deterioration of rotation and boom speed matching, and inability to apply boom and other problems, to achieve the effect of good speed matching and rotation speed suppression

Inactive Publication Date: 2008-10-29

KOMATSU LTD

View PDF2 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For this reason, the operator cannot fully operate the two operating levers 41, 42 in order to match the speed of the boom and the upper rotating body, and must carefully adjust

This requires the operator to be skilled and at the same time leads to deterioration of the operability of the lifting and rotating operation

2) Deterioration of energy loss and fuel consumption rate

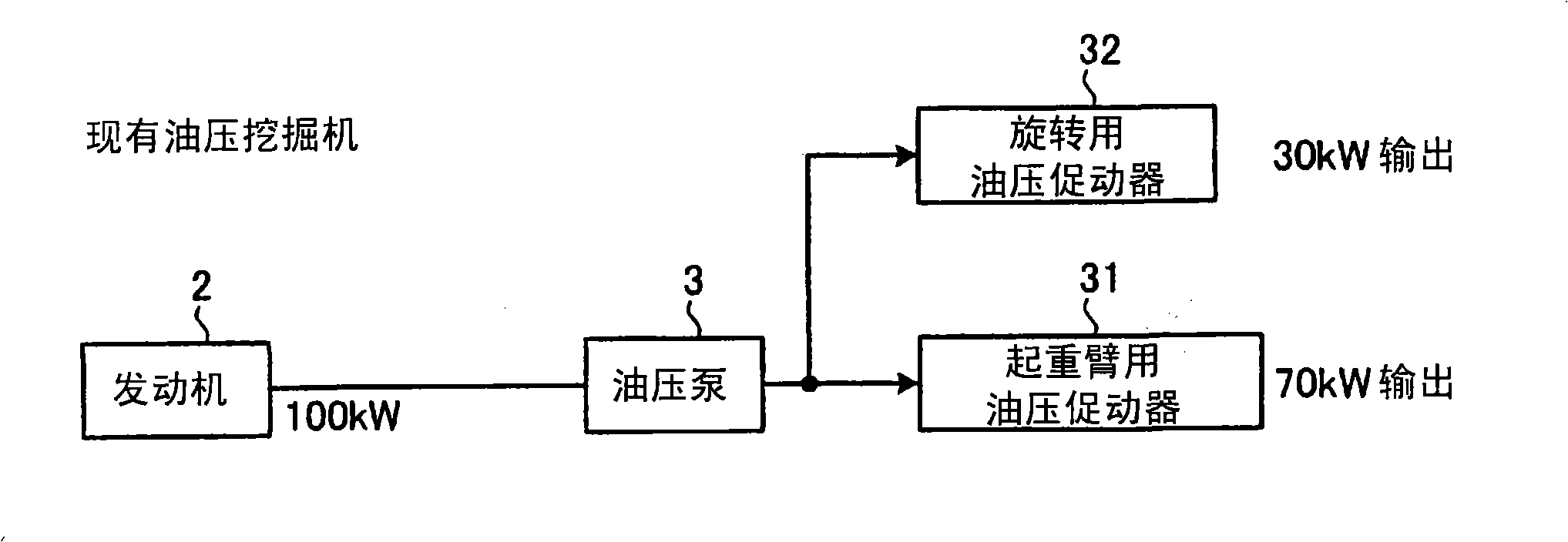

Therefore, 40kW is distributed to the generator motor 11 for rotation, and 80kW is distributed to the hydraulic actuator 31 for the boom, which deviates from the ideal state of power distribution (FIG. 2-1) as in FIG. 2-2. Faster than boom raising speed, resulting in poor match between rotation and boom speed

In addition, the structure shown in FIG. 3 cannot be applied to the boom, rotation, etc., because one actuator for the boom is the hydraulic actuator 31, and the other actuator for the rotation is the electric actuator 11. Existing technology based on the premise that both sides of the actuator are hydraulic actuators

In addition, the techniques described in Patent Documents 1 and 2, which are based on the premise that both the boom and the rotating actuator are hydraulic actuators, cannot be applied.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A control device of a work machine capable of matching the speeds of both a hydraulic actuator and an electric actuator with each other when these actuators are operated in combination with each other. When a hydraulic cylinder (31) for a boom and a power generation motor (11) for turning are determined to be operated in combination with each other by determination parts (71, 72) based on the operating amounts of an operating lever (41) for the boom and an operating lever (42) for turning, the torque of the power generation motor (11) is limited based on a pump discharge pressure Pp and accordingly, for example, a torque limit instruction, for reducing the torque limit value TL2 of the power generation motor (11) as the discharge pressure Pp of a hydraulic pump (3) is reduced, is generated and output. A pump suction power instruction for limiting the suction power Wp of the hydraulic pump (3) is generated to reduce the suction power Wp of the hydraulic pump (3) as a turning output power Wsw is increased. An engine / pump controller (17) controls the hydraulic pump (3) so that the pump suction power of the hydraulic pump (3) does not exceed a calculated pump suction power Wp.

Description

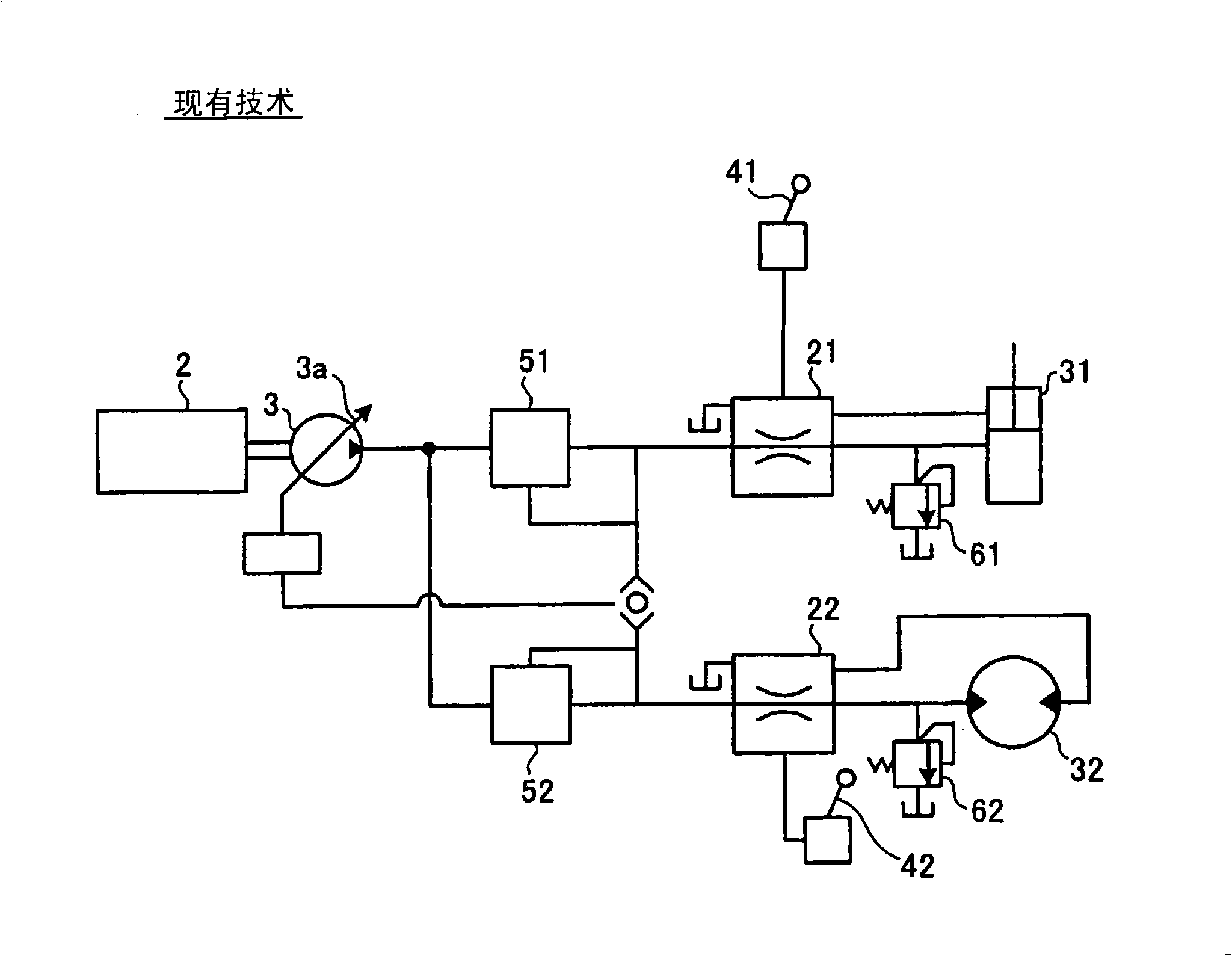

Work machine controls technical field The present invention relates to a control device for a working machine, and in particular to a control device suitable for a hybrid construction machine which utilizes a generator-motor to assist engine driving force. Background technique One of the typical tasks performed by hydraulic excavators is lifting and rotating tasks. Lifting and rotating operation is to load the sand below with the boom, then rotate the upper rotating body at a predetermined angle (for example, 90°) while raising the boom, and load it on the loading platform of the dump truck. During lifting and turning work, the boom operating lever and the turning operating lever are combinedly operated, and the boom is raised and the upper revolving body is rotated at the same time. The configuration of a conventional construction machine 1 will be briefly described with reference to FIG. 1 . In addition, in FIG. 1, for convenience of explanation, only the structure fo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02F9/20E02F9/22F15B11/16F15B21/14

CPCE02F9/2037B66C1/42B66F7/04E02F9/2075

Inventor 森永淳河口正井上宏昭

Owner KOMATSU LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com