Trestle crane barge final assembly technique

A technology for gantry cranes and barges, applied in cranes, trolley cranes, loading/unloading, etc., can solve the problems of manpower, material resources and time, poor safety, affecting shipyard operations, etc., and achieve safe final assembly, far-reaching significance, and solution. The effect of the whole machine being hoisted on board and shipped ashore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

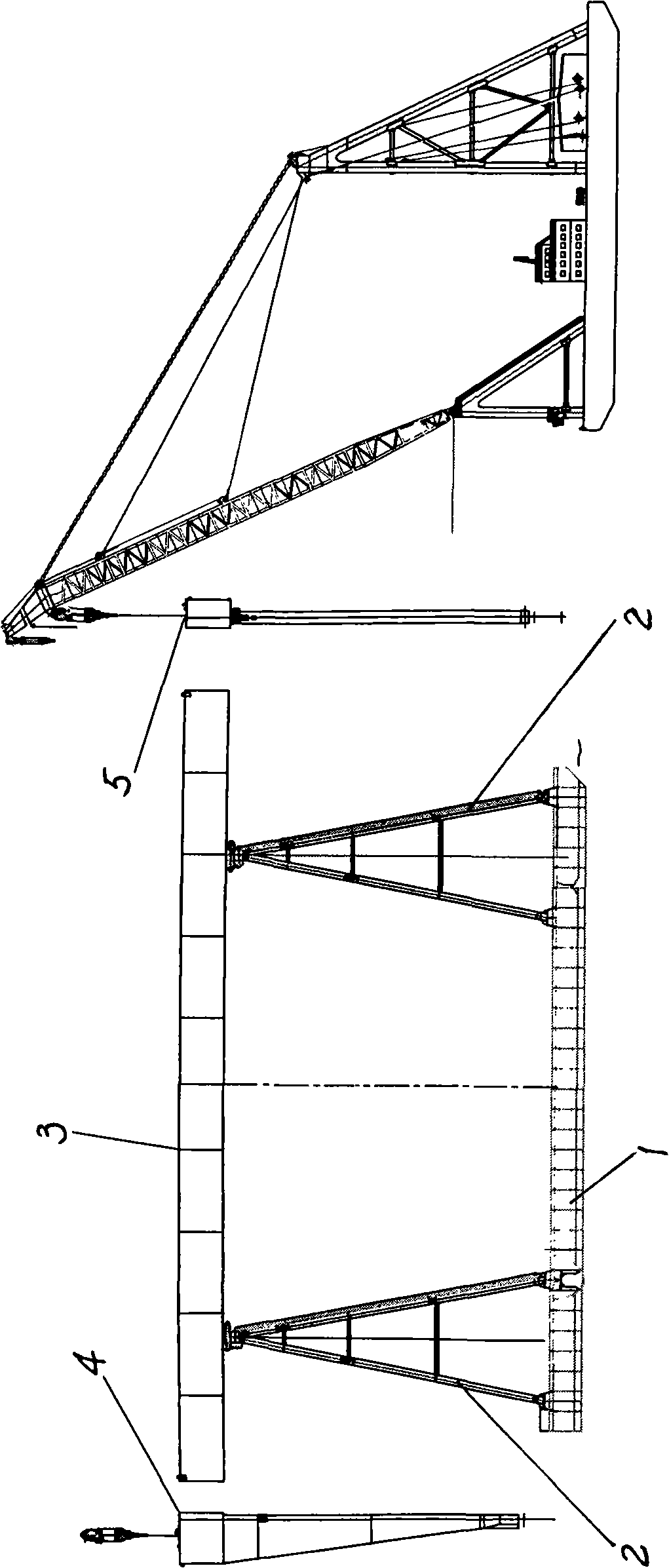

[0013] With reference to accompanying drawing, according to a kind of gantry crane of the present invention in barge assembly technology, at first on deck barge 1, two vertical towers 2 are fixedly installed, make gantry crane straddle deck barge and install. Because the span of the gantry crane is large, the length of the deck barge is not enough, so the gantry crane is supported by two towers 2 arranged on the barge.

[0014] The large-scale components of the gantry crane, including the main girder 3, the rigid leg 4, the flexible leg 5, the traveling mechanism of the cart and the trolley assembly, are pre-assembled at the front of the wharf of the factory.

[0015] Utilize two large-scale floating cranes to hoist the main girder 3 synchronously on two towers 2 welded together with the barge, and connect and fix with the towers.

[0016] Then use the floating crane to hoist the flexible leg 5 that is rigidly connected on the ground in advance and fix it in alignment with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com