Shock-absorbing axle of special-shaped rubber stick

A rubber rod and special-shaped technology, which is applied in the direction of vehicle components, elastic suspensions, suspensions, etc., can solve the problems of small elastic force of leaf spring structure, work reliability, and reduce the stability of the car body, so as to achieve a small damping angle , Improving mobility and lowering the center of gravity of the vehicle

Inactive Publication Date: 2008-10-29

涡阳县康达车桥有限公司

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. The elastic force of the leaf spring structure is too small during use, so that the elastic distance of the trailer under heavy load and no load is too large, up to 95mm, which obviously reduces the stability of the vehicle body

2. Due to the large elastic distance, the noise of the elastic deformation of the leaf spring is relatively large

3. The exposed structural form of the leaf spring makes it very easy to rust, which affects the appearance, and even affects the service life, which brings about work reliability problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

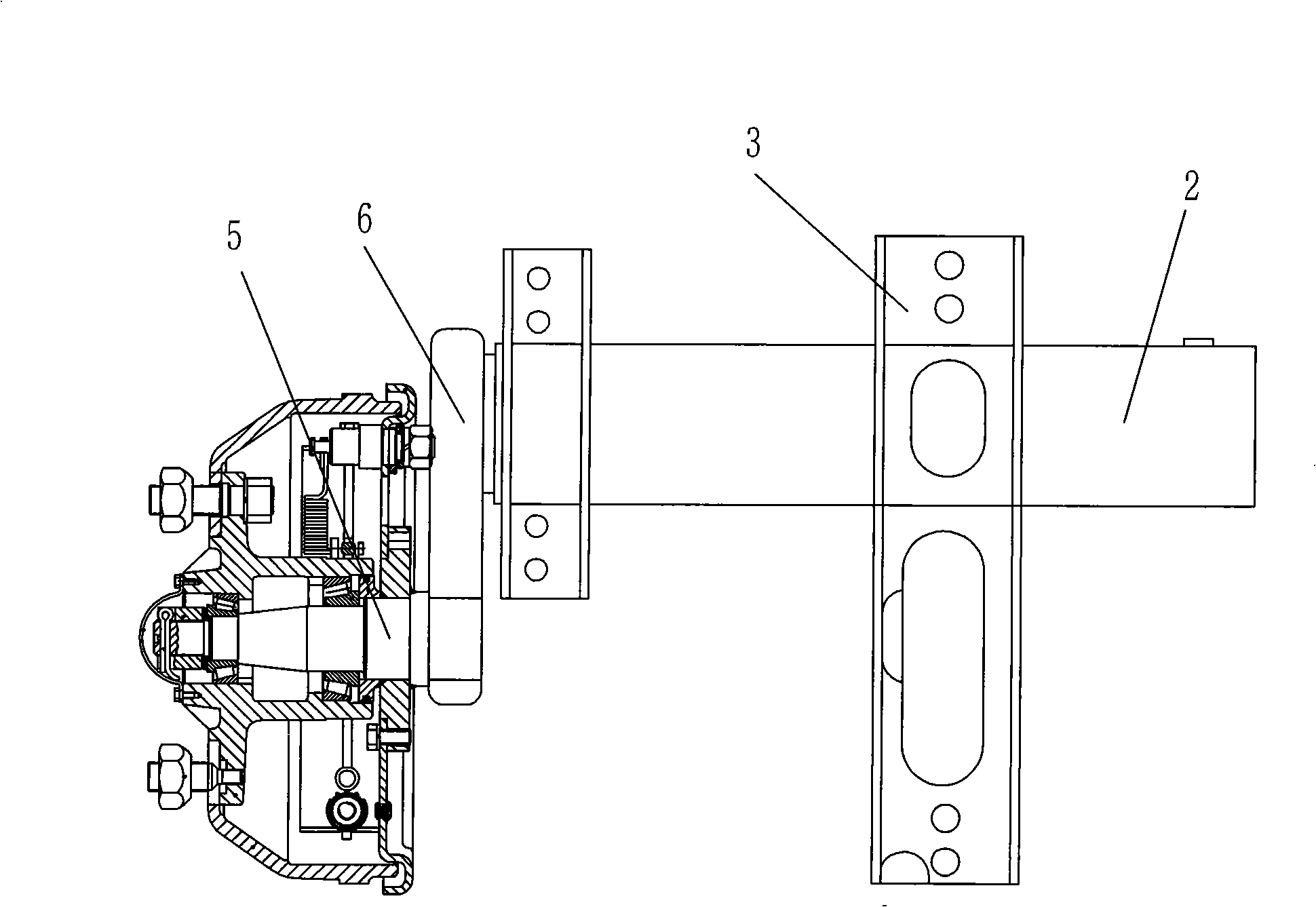

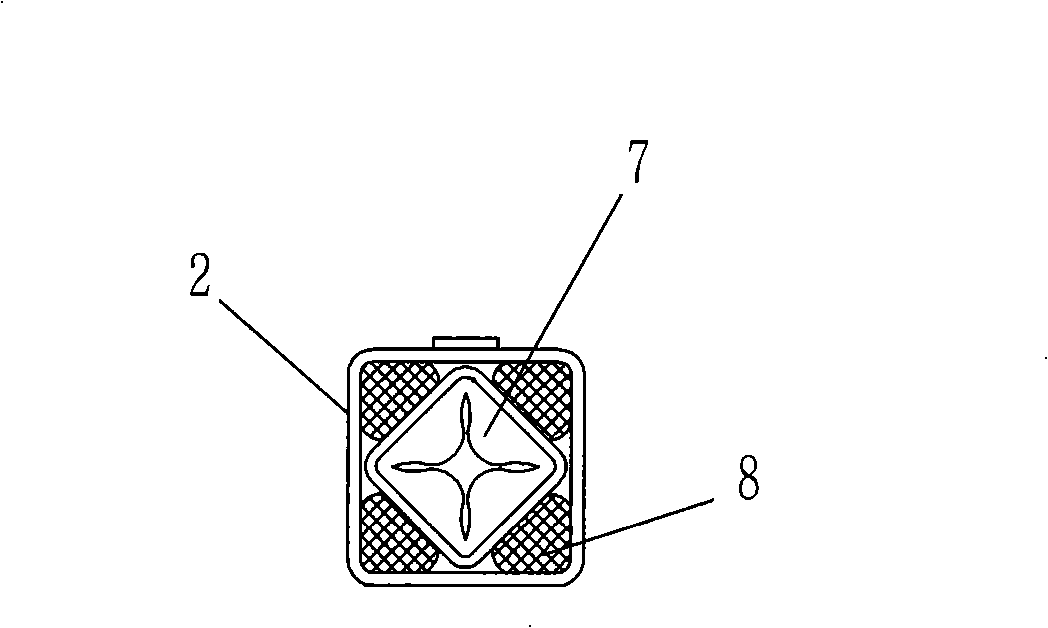

A deformed rubber stick damping axle is characterized by being provided with an outer axle tube; an inner bushing is sheathed in the outer axle tube; the inner bushing and the outer axle tube can form mutual rotation and an empty cavity is formed between the inner bushing and the outer axle tube; an elastomer which forms obstruction to the mutual rotation between the outer axle tube and the inner bushing is pressed and arranged in the empty cavity to form a torsion spring; the outside of the outer axle tube is fixedly provided with a bracket fixedly connected with a carriage or a device; the two ends of the outer axle tube are empty sleeves; the two ends of the inner bushing are respectively and fixedly connected with a torsion arm along the radial direction; the other end of the torsion arm is fixedly connected with a shaft head; the torsion arm and the axes of the shaft head are arranged in 'L' shape; the axle of the invention has the advantages of simple structure and high bearing capacity, which can greatly reduce the elastic distance between empty load and heavy load by the torsion spring, reduces the gravity center of the car body and improves the moving stability of the car body.

Description

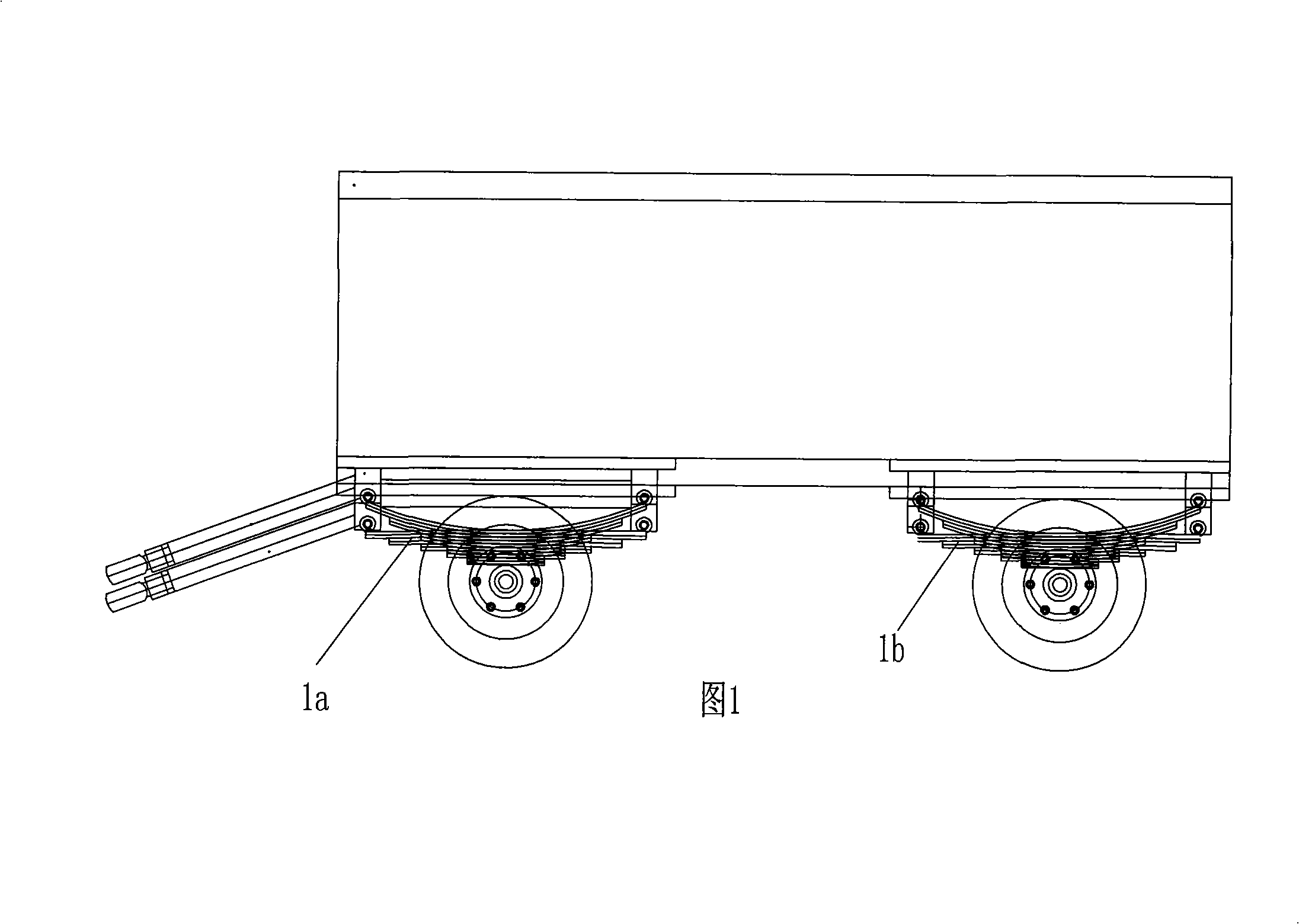

Special-shaped rubber rod shock-absorbing axle technical field The present invention relates to support axles, and more particularly to support axles on mobile trailers in particular. Background technique Referring to Fig. 1, for a long time, the trailer support axle has been equipped with two leaf springs on the axle, including the front leaf spring 1a on the front axle and the rear leaf spring 1b on the rear axle. The elastic deformation of the leaf spring is used to achieve the purpose of shock absorption. Figure 1 shows the shape of the leaf spring under two states of no load and heavy load. In practical application, the following problems are mainly adopted: 1. The elastic force of the leaf spring structure is too small during use, so that the elastic distance of the trailer under heavy load and no load is too large, up to 95mm. This form obviously reduces the stability of the vehicle body. 2. Due to the large elastic distance, the noise when the leaf spring is el...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B60G11/18

Inventor 韩志业王国廷吴义

Owner 涡阳县康达车桥有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com