Intelligently balancing liquid-discharge system of vacuum filtration machine

A vacuum filter and intelligent technology, applied in the field of negative pressure liquid discharge device and new intelligent balance liquid discharge device, can solve the problems of increasing vacuum pumping volume and power, increasing energy consumption, reducing equipment vacuum, etc., to achieve stable liquid discharge effect, reduce energy consumption and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

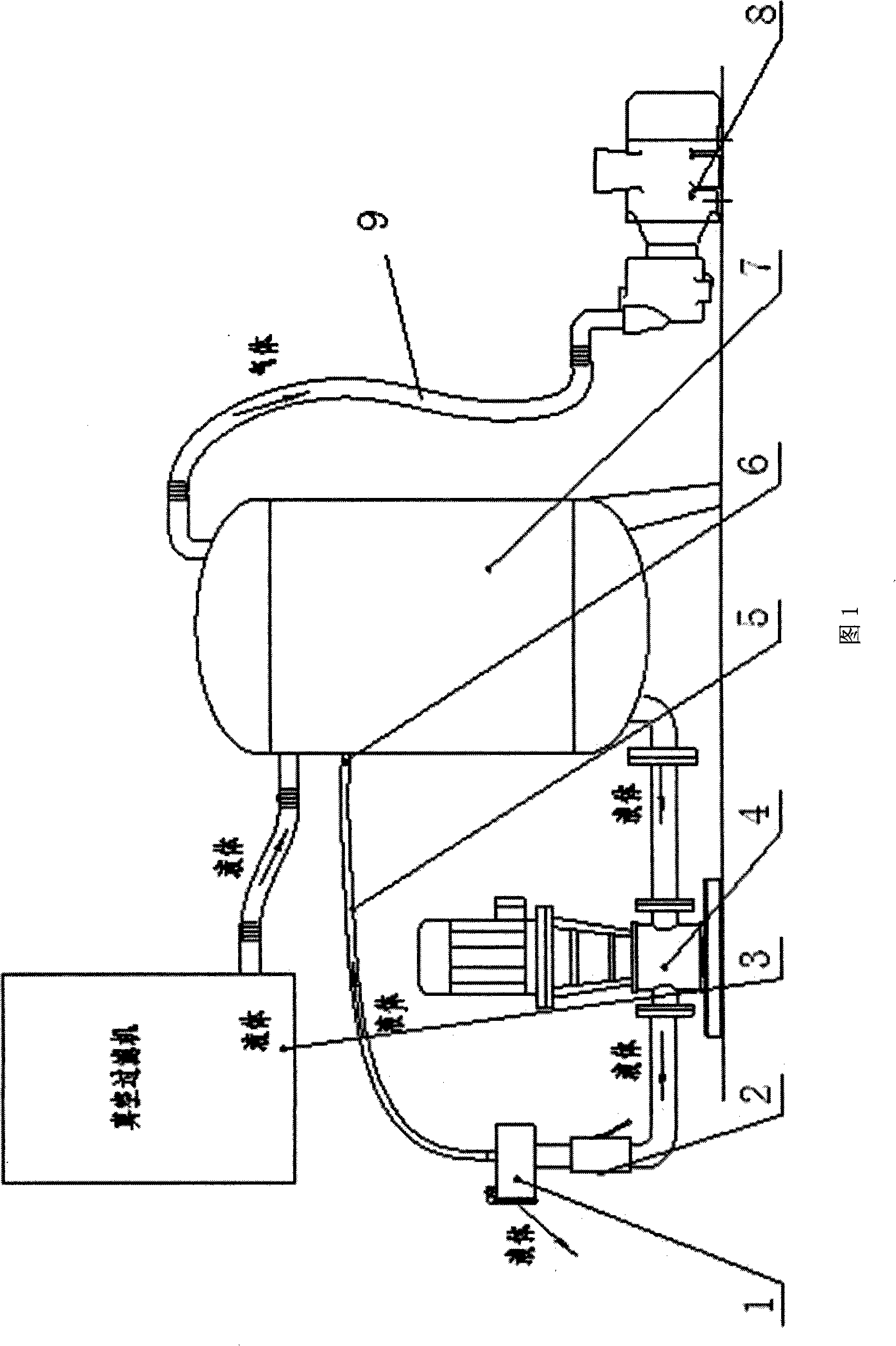

[0024] Referring to FIG. 1 , the technical solution of the present invention will be specifically described through embodiments, but the present invention is not limited to the following embodiments.

[0025] In this embodiment, the vacuum filter intelligent balanced drainage system, the energy-saving auxiliary drainage system includes a vacuum pump 8, the vacuum pump 8 is connected to the upper end of the drainage tank 7 through a hose, and the side interface of the drainage tank 7 is connected to the vacuum filter 3 equipment, A stable vacuum system is formed between the equipment connections, the filtrate pump 4 is connected to the drain tank 7 through a pipeline, the automatic drain valve 1 is connected to the filtrate pump 4 through a pipeline, and the automatic drain valve 1 is drained through a hose 5 and The gas nozzle 6 on the tank is connected to form an auxiliary drainage system.

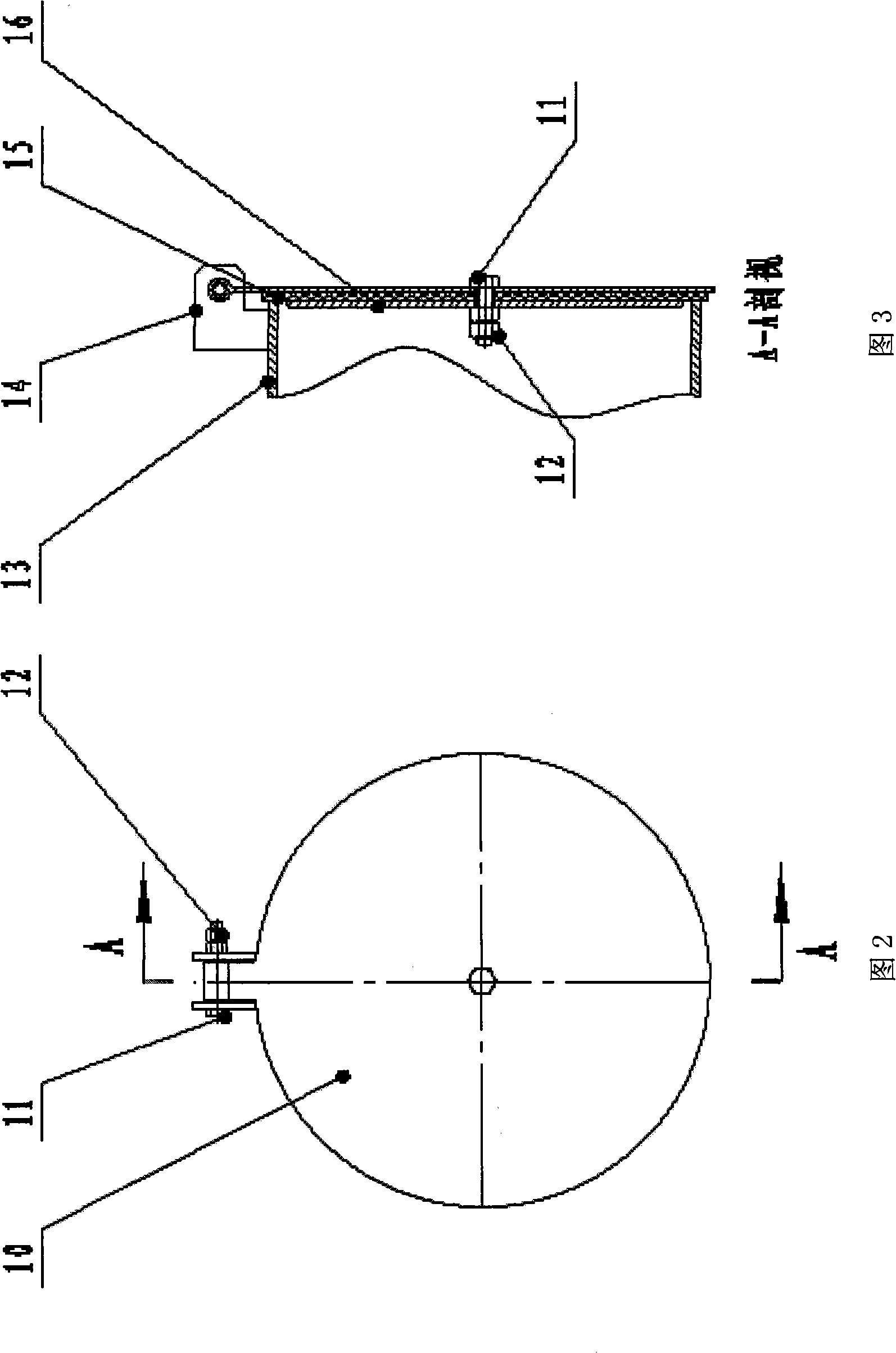

[0026] The automatic drain valve 1 includes a valve plate 10, bolts 11, nuts 12, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com