Manufacturing method of control device for low-voltage isolation technique

A technology control, low-voltage power grid technology, applied in circuit devices, emergency protection circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve three-phase load imbalance, electric shock damage, failure to reach Design effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the drawings and specific implementations:

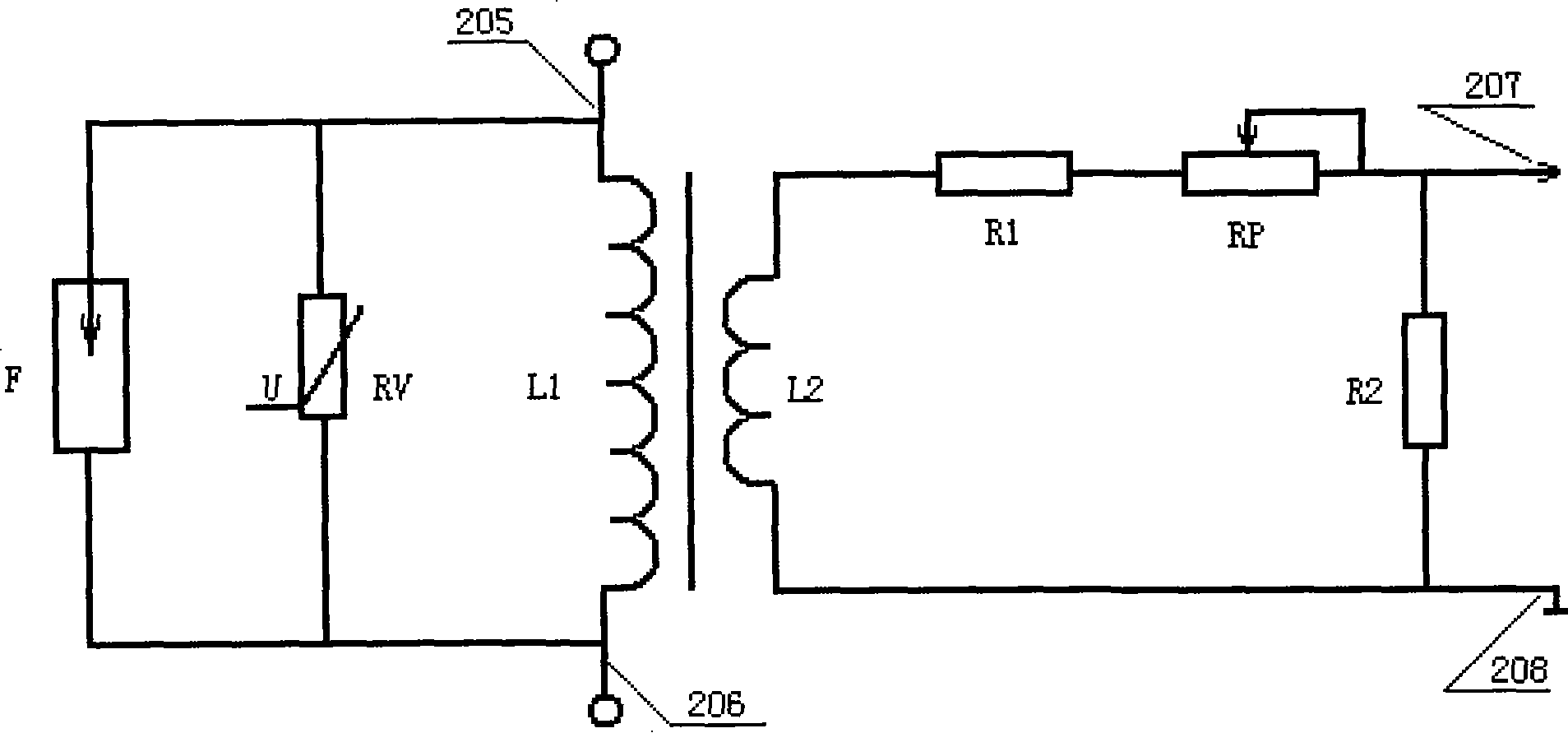

[0017] Such as figure 1 As shown, a low-voltage power grid isolation technology control device includes an overvoltage prevention device RV, a lightning protection device F, an isolation transformer with a primary winding L1 and a secondary winding L2, an adjustable resistor RP, a resistor R1 and Resistance R2;

[0018] Wherein, the primary winding L1 of the isolation transformer, the overvoltage prevention device RV, and the lightning protection device F are connected in parallel, and the head ends of the aforementioned components are connected to form the head end 205 of the low-voltage power grid isolation technology control device. The connected tail ends of the components constitute the tail end 206 of the low-voltage power grid isolation technology control device;

[0019] The secondary winding L2 of the isolation transformer is sequentially c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com