Liquid crystal display panel and its substrate preparation method

A liquid crystal display panel and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of lowering the display quality and practicability of liquid crystal display panels, gray spots, residual pollution sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

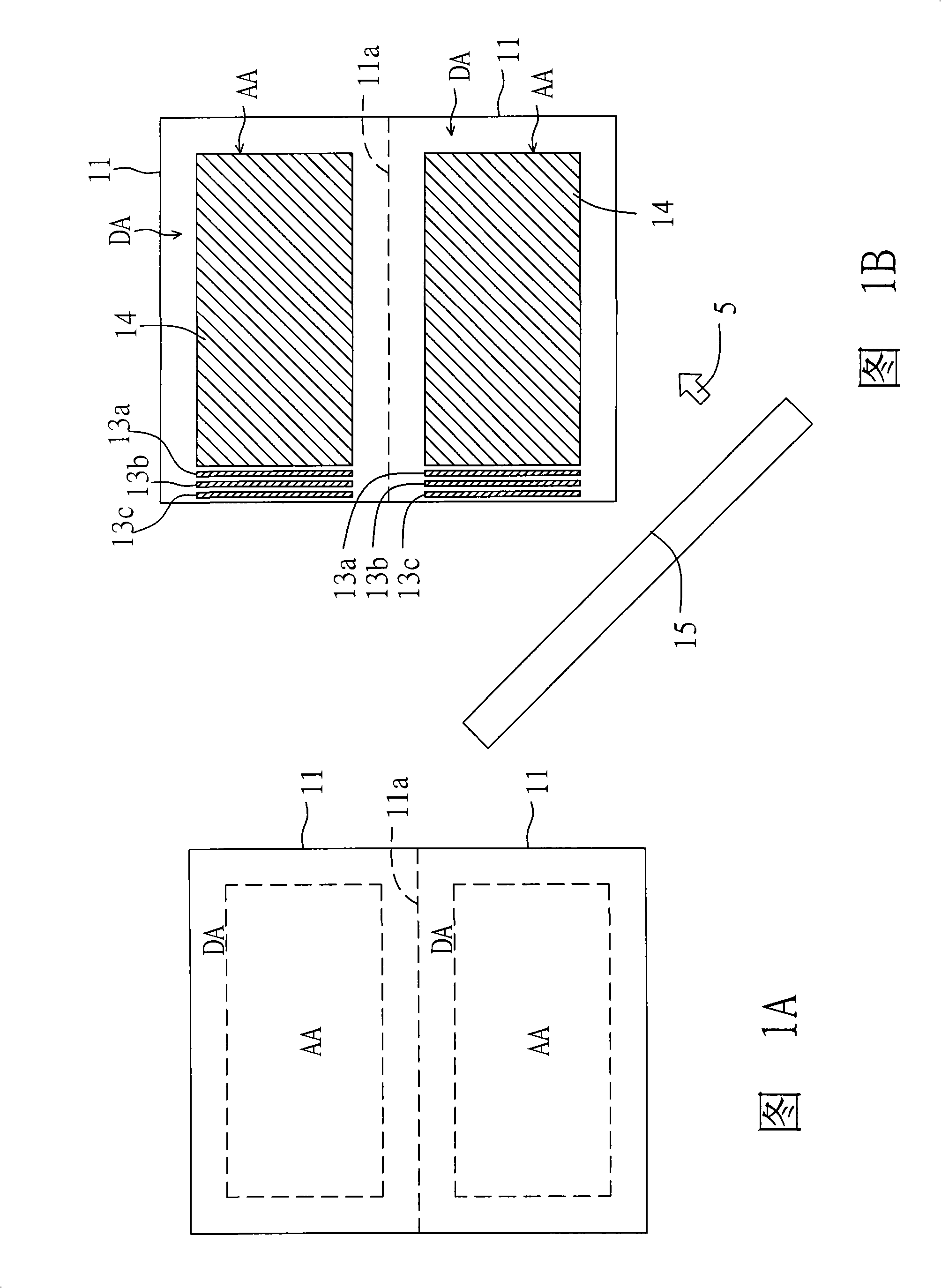

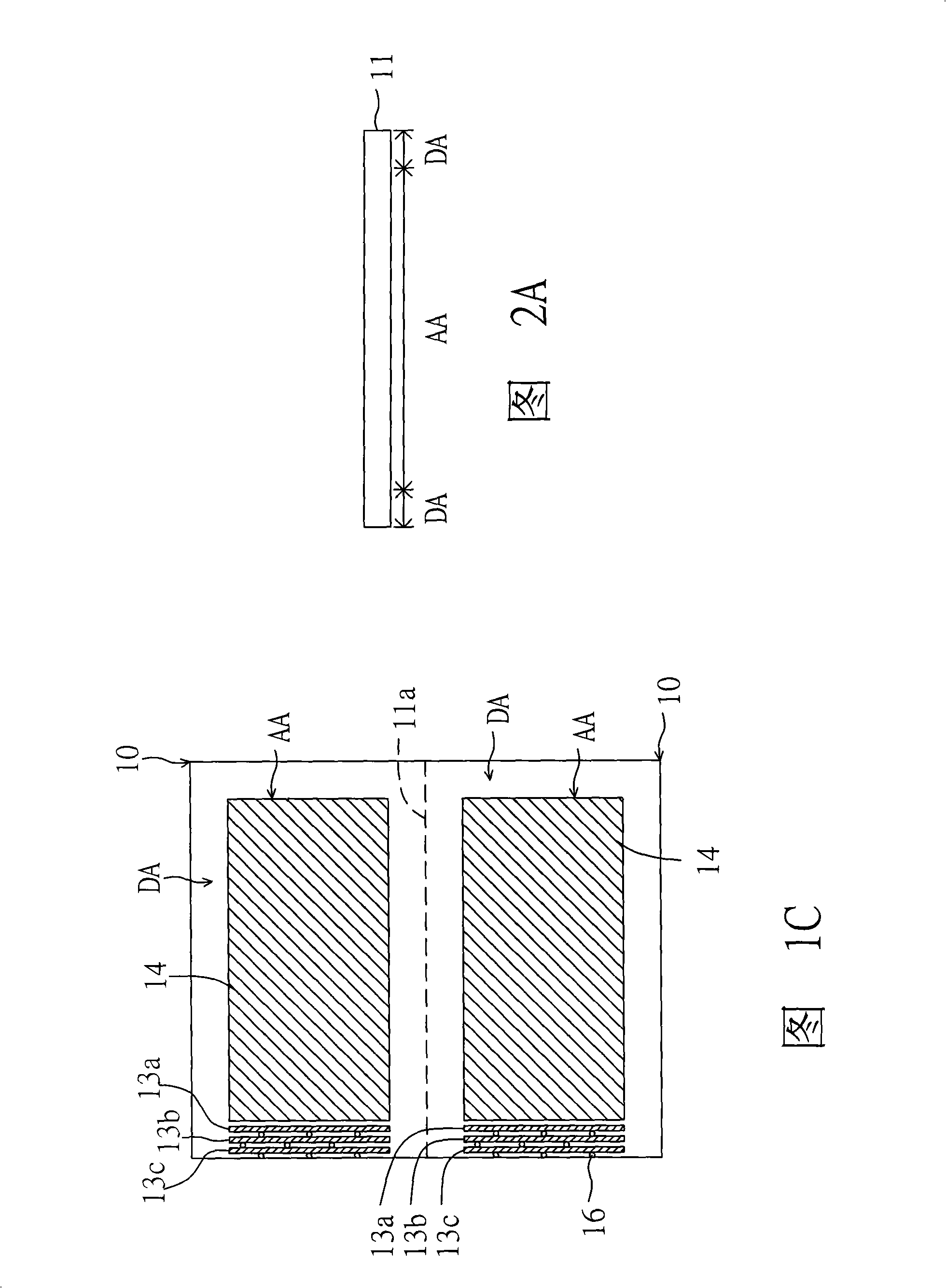

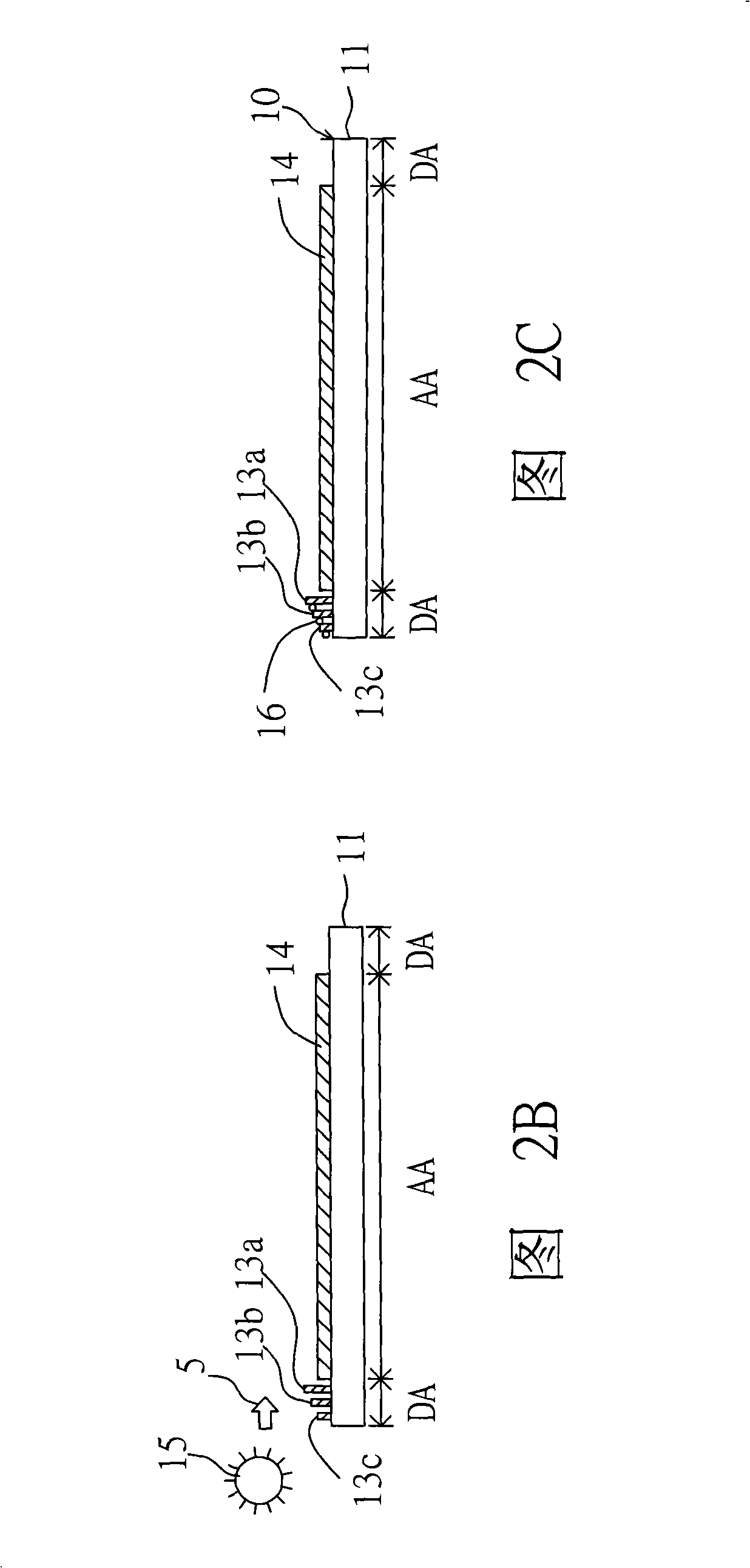

[0020] Please refer to FIG. 1A to FIG. 2C at the same time. FIG. 1A to FIG. 1B are top views of the manufacturing process of the substrate of the liquid crystal display panel according to Embodiment 1 of the present invention, and FIG. 2A to FIG. Process cross-section of the substrate. First, referring to FIG. 1A and FIG. 2A , a substrate 11 is provided, and a display area AA and a surrounding non-display area DA are defined on the substrate 11 . Wherein, the display area AA corresponds to the pixel array area and the liquid crystal filling area of the liquid crystal display panel, and the surrounding non-display area DA corresponds to the external circuit connection area of the liquid crystal display panel. In addition, it is possible to divide, for example, two small-area substrates 11 in a large-area substrate, and define a cutting line 11 a between the two substrates 11 .

[0021] Next, as shown in FIG. 1B and FIG. 2B, an alignment film 14 and several barrier walls ar...

Embodiment 2

[0027] Please refer to FIG. 3 , which is a top view of a substrate of a liquid crystal display panel according to Embodiment 2 of the present invention. The difference between the substrate 20 of the liquid crystal display panel of the present embodiment and the substrate 10 of the liquid crystal display panel of the first embodiment lies in the barrier walls 23 a - 23 c , and the rest of the same constituent elements continue to use reference numerals and will not be repeated.

[0028] As shown in FIG. 3, the retaining walls 23a-23c are discontinuously arranged in the surrounding non-display area DA, and located outside the central non-display area AA, and have almost the same height or different heights to form heights. segment difference. The blocking wall 23a is closest to the display area AA, while the blocking wall 23c is farthest from the display area AA. The heights of the retaining walls 23a-23c gradually increase from the edge of the substrate 11 to the edge of the ...

Embodiment 3

[0030] Please refer to FIG. 4 , which is a top view of a substrate of a liquid crystal display panel according to Embodiment 3 of the present invention. The difference between the substrate 30 of the liquid crystal display panel of this embodiment and the substrate 10 of the liquid crystal display panel of the first embodiment lies in the barrier walls 33 a - 33 c. The rest of the same constituent elements continue to use the labels and will not be repeated.

[0031] As shown in FIG. 4 , the retaining walls 33 a - 33 c are continuously disposed in the peripheral non-display area DA and surround the central non-display area AA, and have almost the same height or different heights to form height differences. The blocking wall 33a is closest to the display area AA, while the blocking wall 33c is farthest from the display area AA. Wherein, the blocking walls 33 a - 33 c are used to block pollution sources from the display area AA after the rubbing alignment of the alignment film 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com