Air conditioner filter screen self-cleaning device

A filter and self-cleaning technology, which is applied in air-conditioning systems, dispersed particle filtration, transportation and packaging, etc., can solve the problems of unsatisfactory dust removal effect, poor suction effect, poor dust removal effect, etc., and achieves wide dust removal range, convenient loading and unloading, Good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

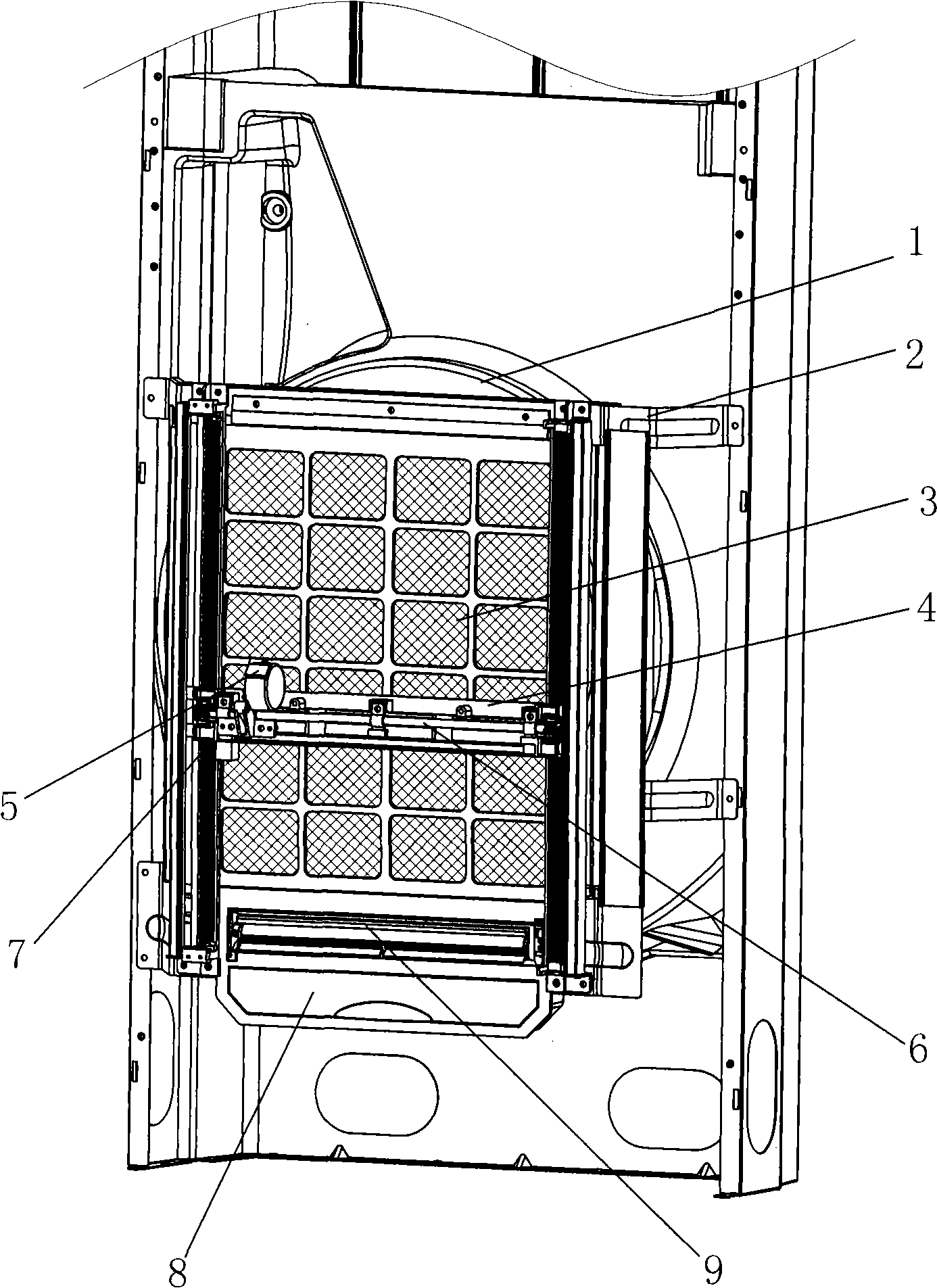

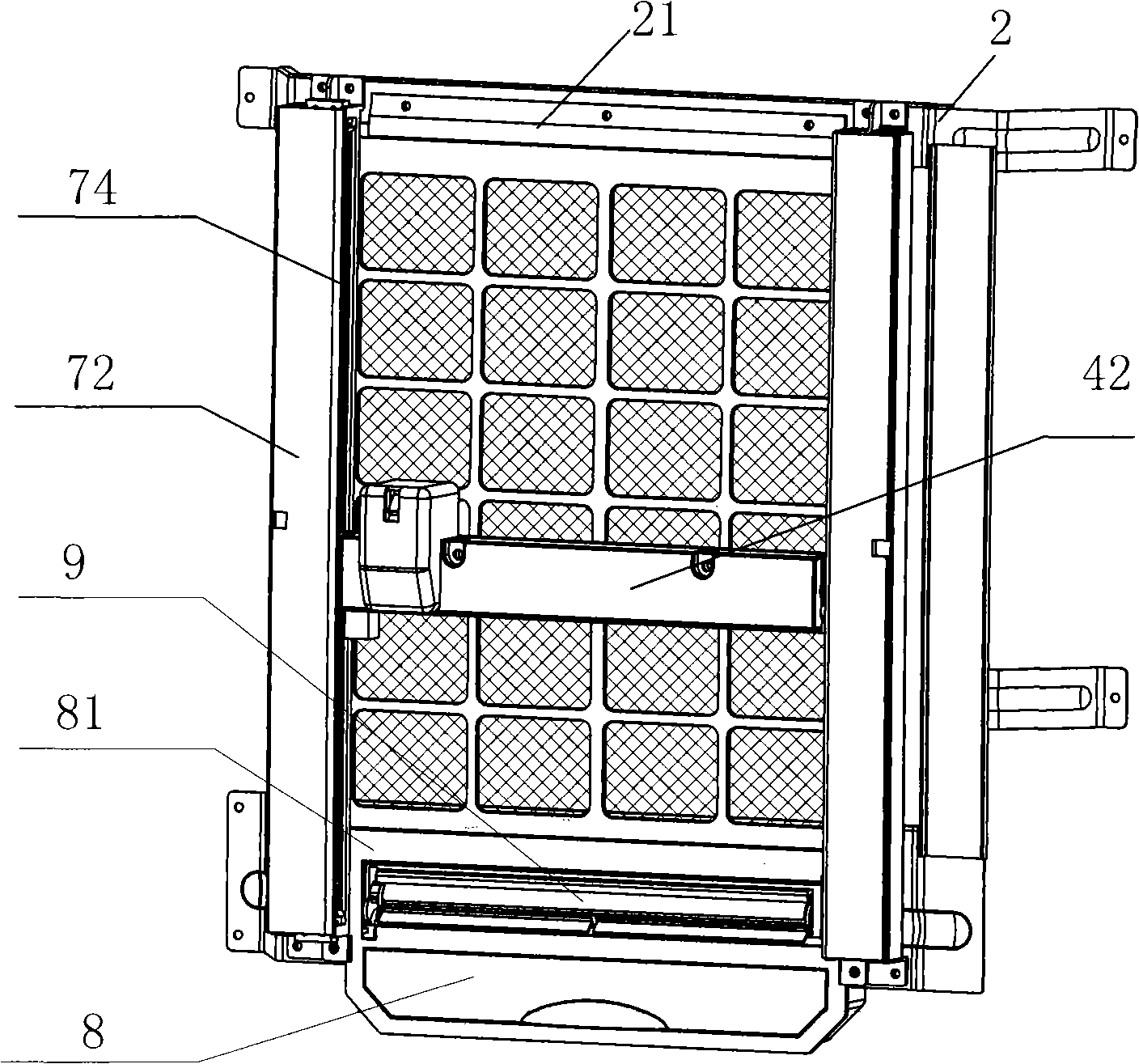

[0022] Such as figure 1 As shown, the air conditioner filter screen self-cleaning device of the present invention is installed on the filter screen support 2 at the air inlet of the air duct volute 1 of the cabinet type air conditioner, and is located on the outside of the filter screen 3, and the filter screen support 2 is fixed At the air inlet of the volute 1, filter screen guide rails 21 with slots are installed on the upper and lower brackets, and the filter screen 3 is fixed on the filter screen support 2 through the slots of the guide rails. During the operation of the air conditioner, the air is sucked into the volute of the air duct by the fan through the filter, and then blown into the room after passing through the heat exchanger, and the dust in the air is absorbed on the filter. After a period of operation, it is filtered through timing or manual control. The net cleaning device works, and the dust brush is discharged into the dust box.

[0023] The filter screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com