Production control and real time information processing method

An information processing method and production control technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of control without production practice details, management, response lag, etc., achieve real-time remote production control, improve production Ability to achieve agile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

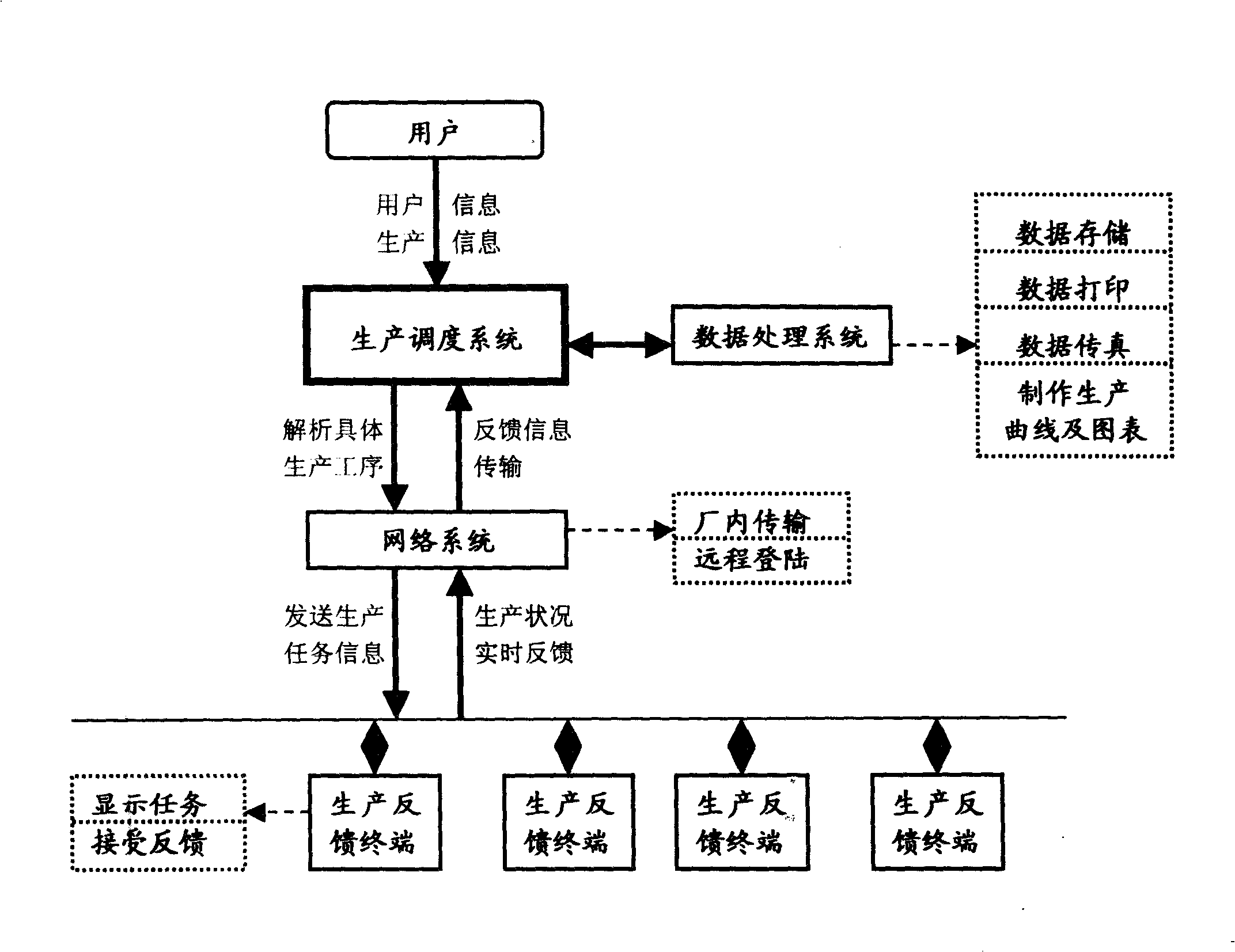

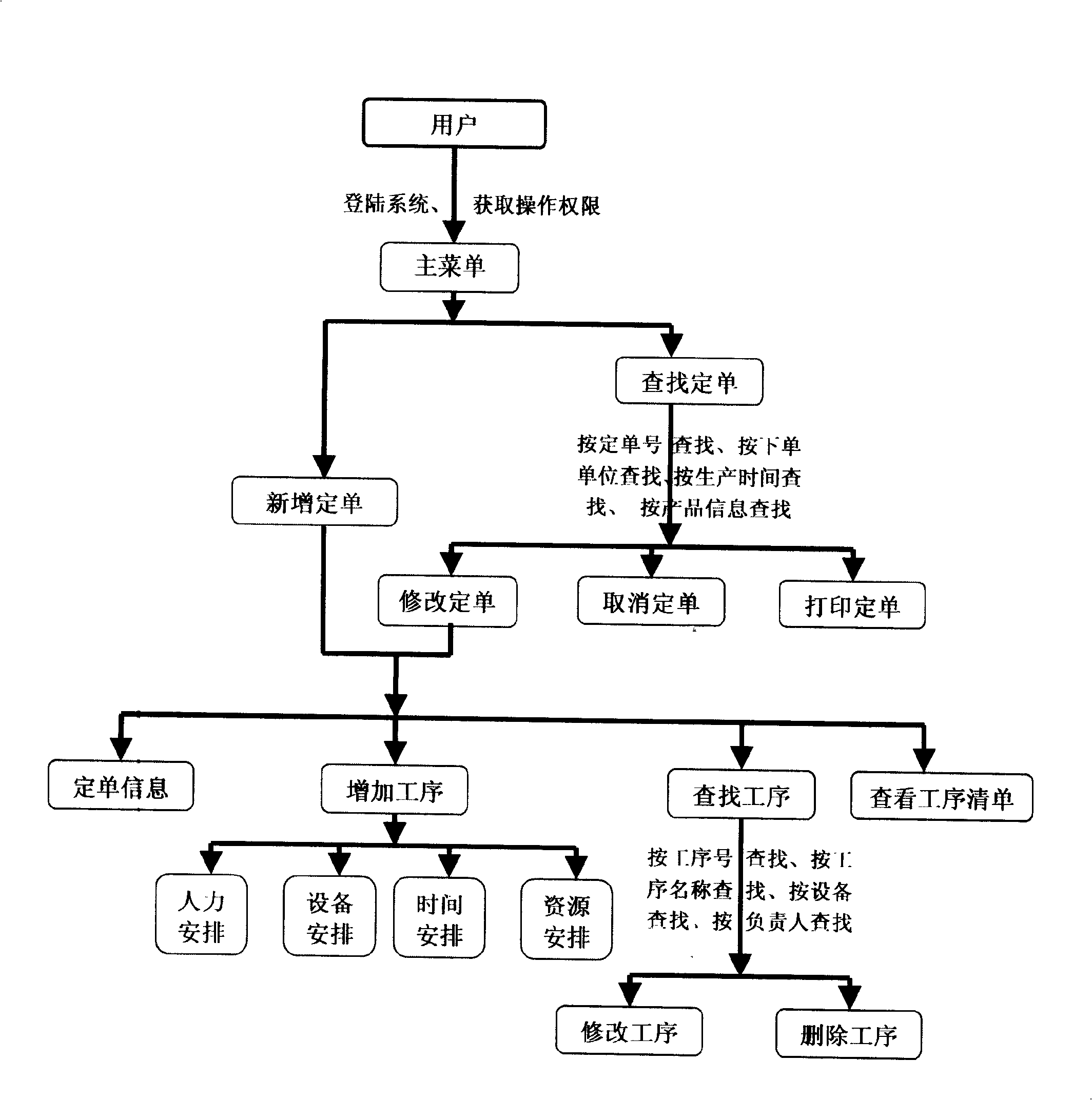

[0012] A production control and real-time information processing method, including a production scheduling system, a data processing method, a network system and four production feedback terminals;

[0013] The production scheduling system includes processes such as adding new orders and adding production processes, searching for orders, and modifying orders;

[0014] Data processing methods include data storage, data printing, data fax and other processes; production curves and charts can be drawn to find production bottlenecks and production loopholes. By comparing with historical production curves, it is also possible to quantify changes in production efficiency to measure the actual impact of various improvements and changes on production efficiency.

[0015] The network system can be divided into the enterprise intranet and the Internet: the enterprise intranet realizes the interconnection of production scheduling, various production links, and various production departme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com