Process for decreasing deposit at reaction chamber in metal etching process

A reaction chamber and deposition technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as poor adhesion and yield impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

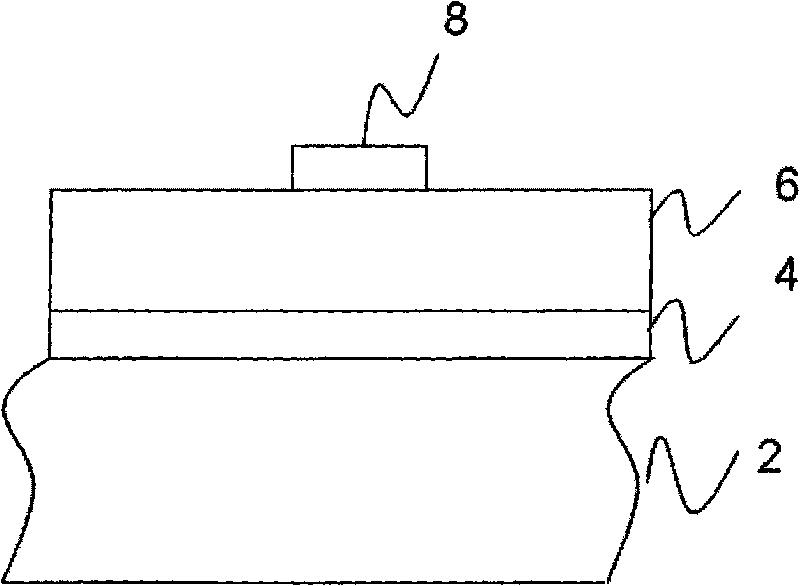

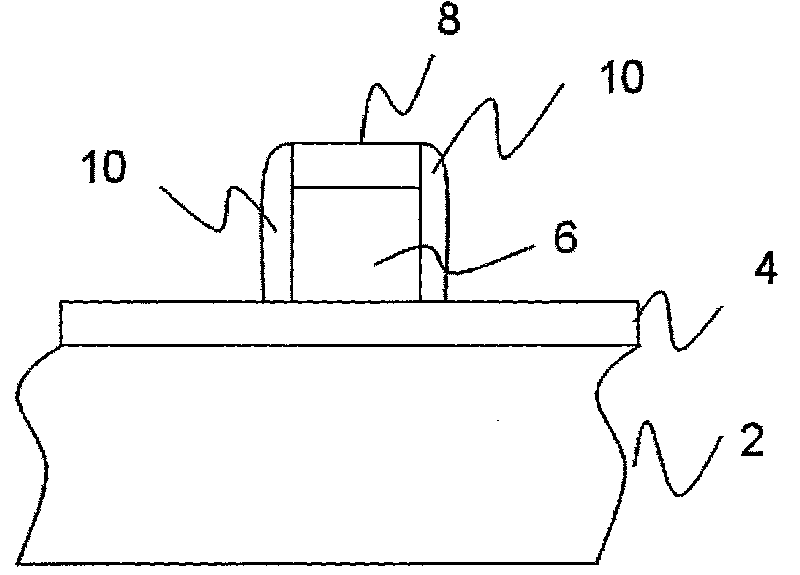

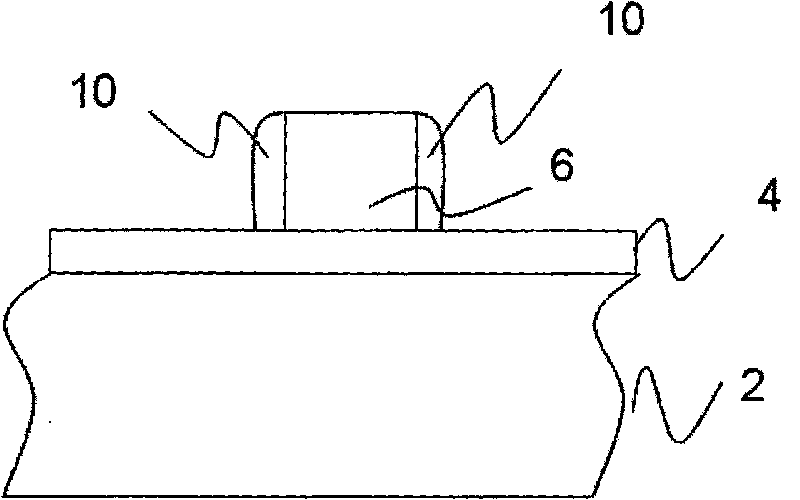

[0026] In order to explain more clearly how to reduce the deposition in the reaction chamber in the aluminum metal process, please refer to Figure 1 and figure 2 . Figure 1(a) to Figure 1(d) It is a structural cross-sectional view of carrying out the aluminum process of the present invention; figure 2 It is a schematic flow sheet of the present invention to reduce aluminum process deposit method; simultaneously refer to Fig. 1 and figure 2 Shown, the method provided by the present invention comprises the following steps:

[0027] First, step S10 is performed to provide a substrate 2 with MOS semiconductor components as shown in FIG. 4. It is usually composed of titanium nitride, and an aluminum metal conductive layer 6 is deposited on the surface of the dielectric layer 4 . Finally, a patterned photoresist coating 8 is formed on the surface of the aluminum metal conductive layer 6 .

[0028] Using the patterned photoresist coating 8 as a mask, an etching technique is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com