Closed-type glasses valve with cleaning unit

A cleaning device and closed technology, which is applied in the direction of valve devices, sliding valves, engine components, etc., can solve the problems of consuming manpower, material resources and time, blockage of valve pipes, continuous production, etc., so as to prolong the service life and reduce the periodical The frequency of maintenance, the effect of guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

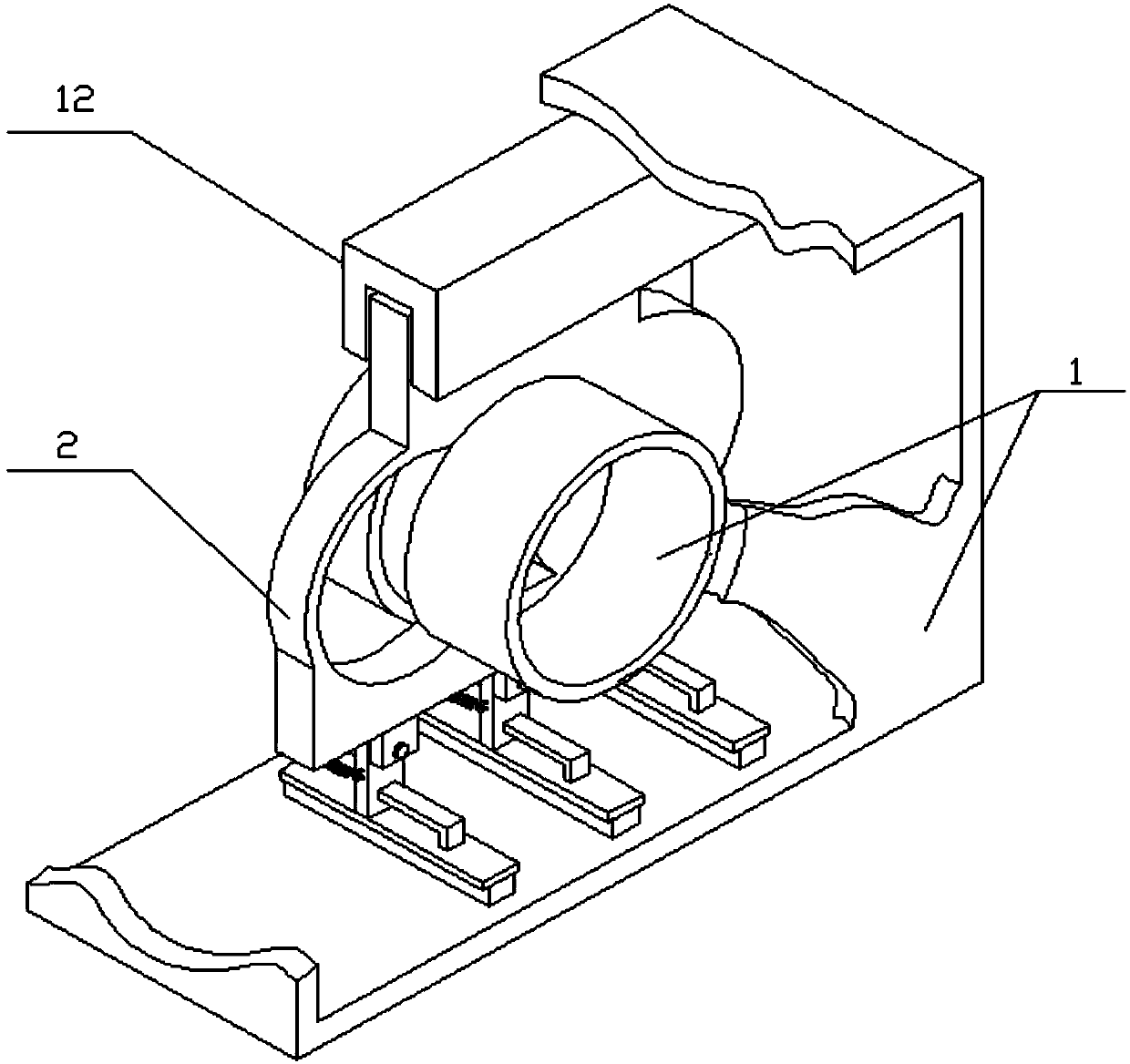

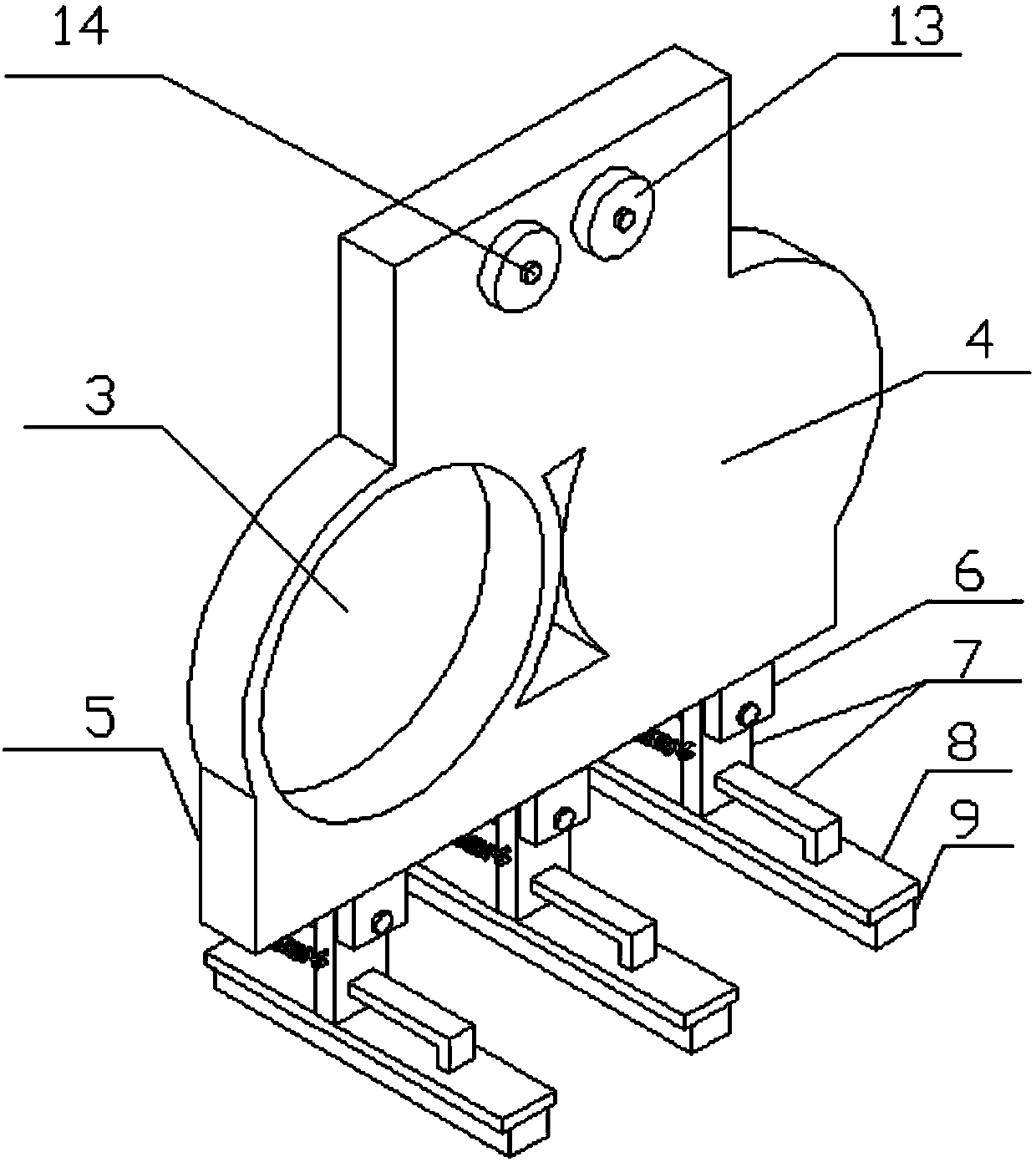

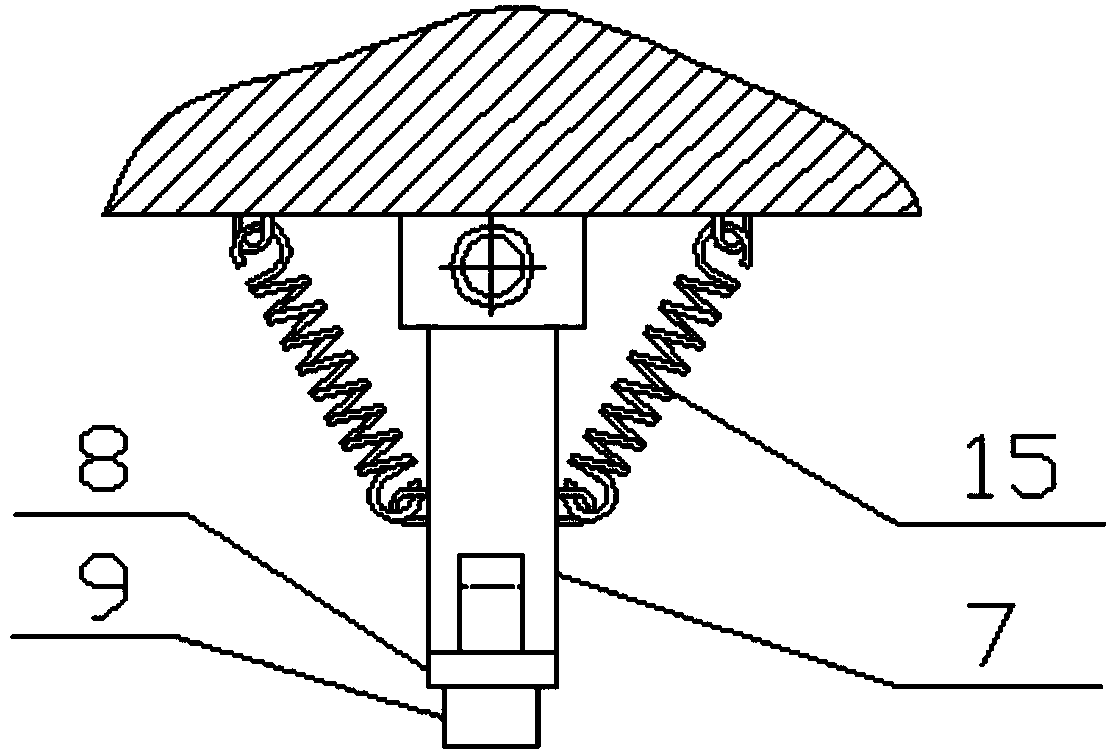

[0017] Specific embodiment 1, such as Figure 1 to Figure 4 As shown, the upper end of the valve body 1 is provided with a guide rail 12, and the installation direction of the guide rail 12 is the same as the arrangement direction of the through hole section 3 and the blind plate section 4. Rollers 13 are arranged on both sides of the upper end of the valve plate 2 to cooperate with the guide rail 12. The rollers 13 is connected to the upper end of the valve plate 2 through the rotating shaft 14. When the glasses valve is working, the valve plate 2 moves left and right along the guide rail 12 through the roller 13 so that the through hole section 3 and the blind plate section 4 are alternately matched with the valve body, thereby realizing the glasses valve. On and off. The bottom of the connecting plate 5 is symmetrically provided with return springs 15 on both sides of the cleaning support 7, and the upper ends of the return springs 15 on both sides are fixedly connected wit...

specific Embodiment 2

[0018] Specific embodiment 2, as a further improvement to embodiment 1, there are three cleaning devices, and the three cleaning devices are respectively located at the middle part and both ends of the connecting plate 5, so that the cleaning effect can be guaranteed and too many cleaning devices can be avoided. Clean the device.

[0019] The present invention adds a cleaning device on the basis of the existing spectacle valve, uses the left and right movement of the valve plate to drive the cleaning device to clean the bottom of the valve body, saves the manpower, material resources and time required to disassemble the spectacle valve after stopping the machine, and ensures The continuous production produces unexpected effects other than the cleaning function, and the service life of the valve body is extended. The invention has a simple design structure, easy operation, and is easy to be popularized and applied in related industries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com