Bursting ejection double anti-forge bottle cap

A technology of anti-counterfeit caps and broken tops, which is applied in capping, bottle/container caps, and capping containers tightly with caps, etc. It can solve the problems of great difficulty in production, scrapping of caps and bottles as a whole, complex processing and assembly processes, etc. Achieve the effect of increasing product reliability and practicability, avoiding welding waste, and outstanding anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

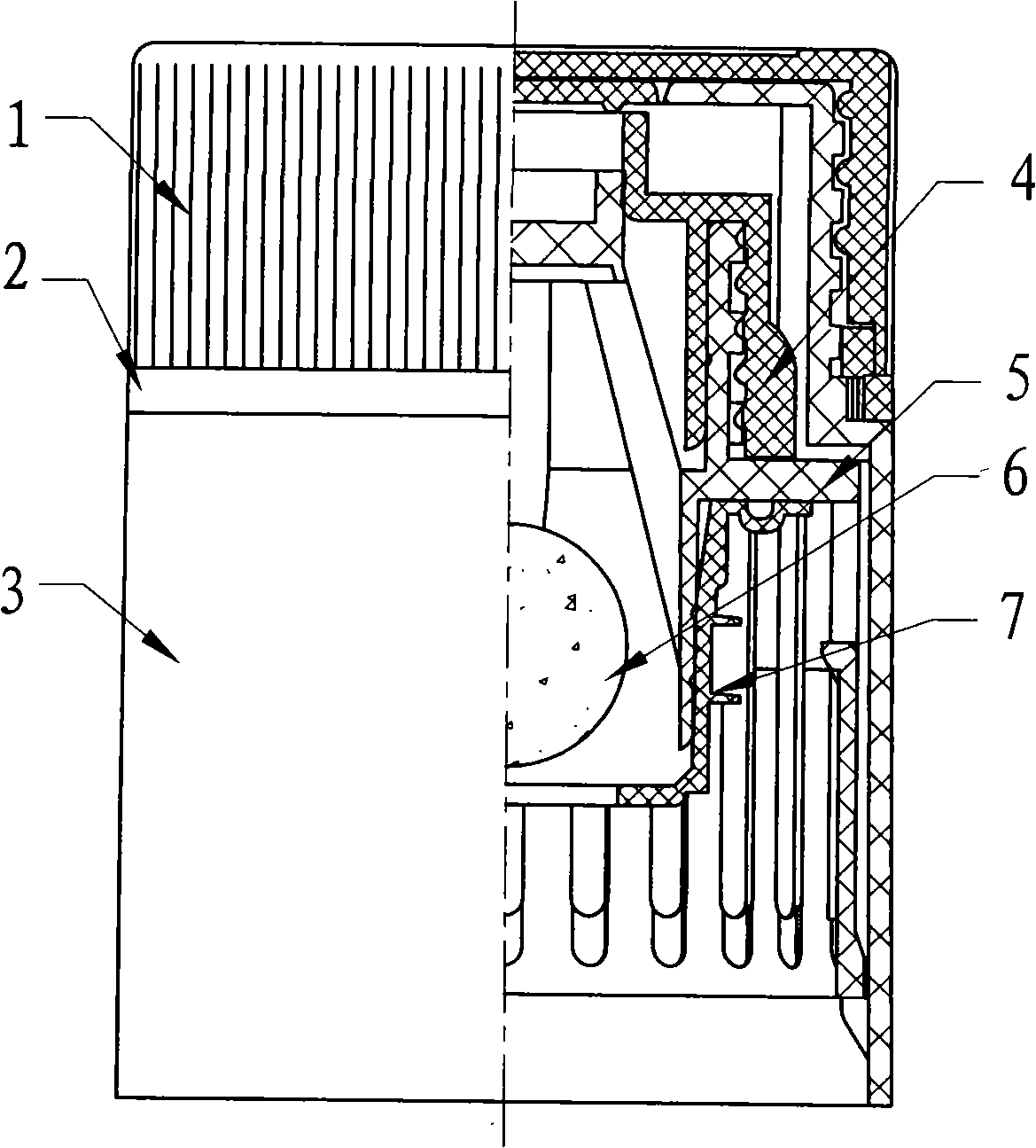

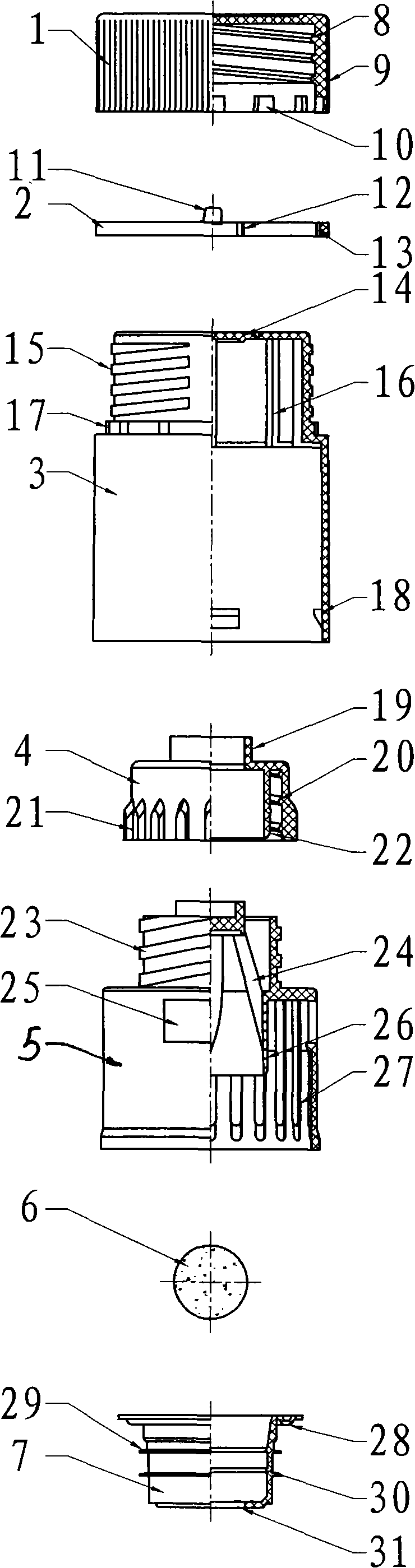

[0016] The present invention mainly consists of the lower sleeve 3, the upper cover 1 and the safety ring 2 sleeved on the upper part of the lower sleeve 3, and the inscribed cover 4 and the middle sleeve 5 connected by thread engagement in the lower sleeve 3 are placed in the middle sleeve 5 The glass beads 6 and inner plug 7 etc. constitute. The upper cover 1 is provided with anti-slip ribs 9 to prevent slippery hands when rotating, and an internal thread 8 and a fixed opening 10 are provided inside. The safety ring 2 is provided with a burst opening 12 , a burst tooth 13 , and a fixing rib 11 fitted with the fixing opening 10 . The top of the lower sleeve 3 is provided with an ejector piece 14 with three feet, the upper part is provided with an external thread 15 mating with the internal thread 8, and a bursting tooth groove 17 fitted with the bursting tooth 13; the inner wall of the lower sleeve 3 The top is provided with anti-rotation tooth groove 16, and the bottom is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com