Flotation pillar special for fly ash

A flotation column and fly ash technology, applied in flotation, solid separation and other directions, can solve the problems of no use value, high loss on ignition, high carbon content in fly ash, and improve flotation efficiency and flow stability. The effect of improving the performance and improving the coal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

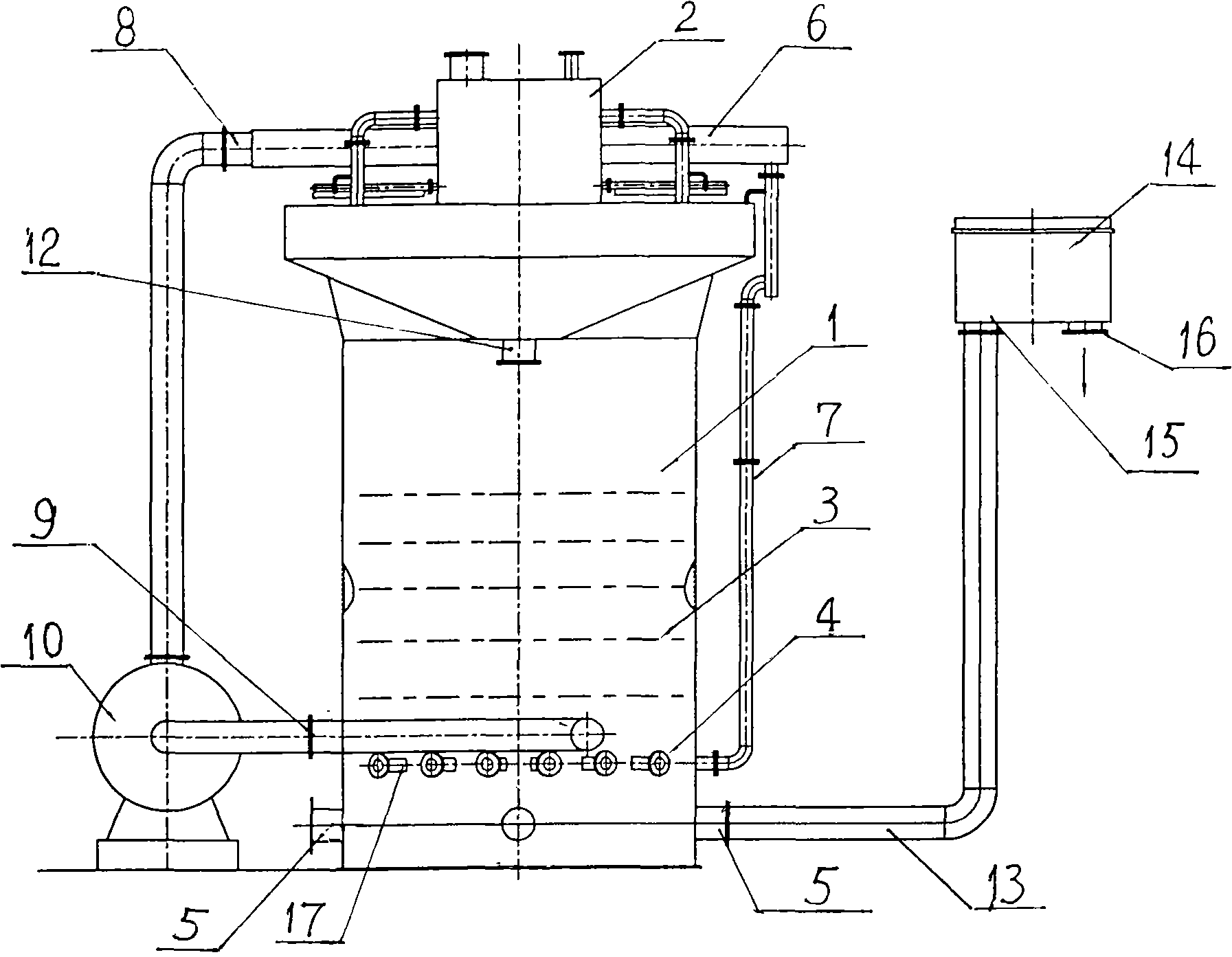

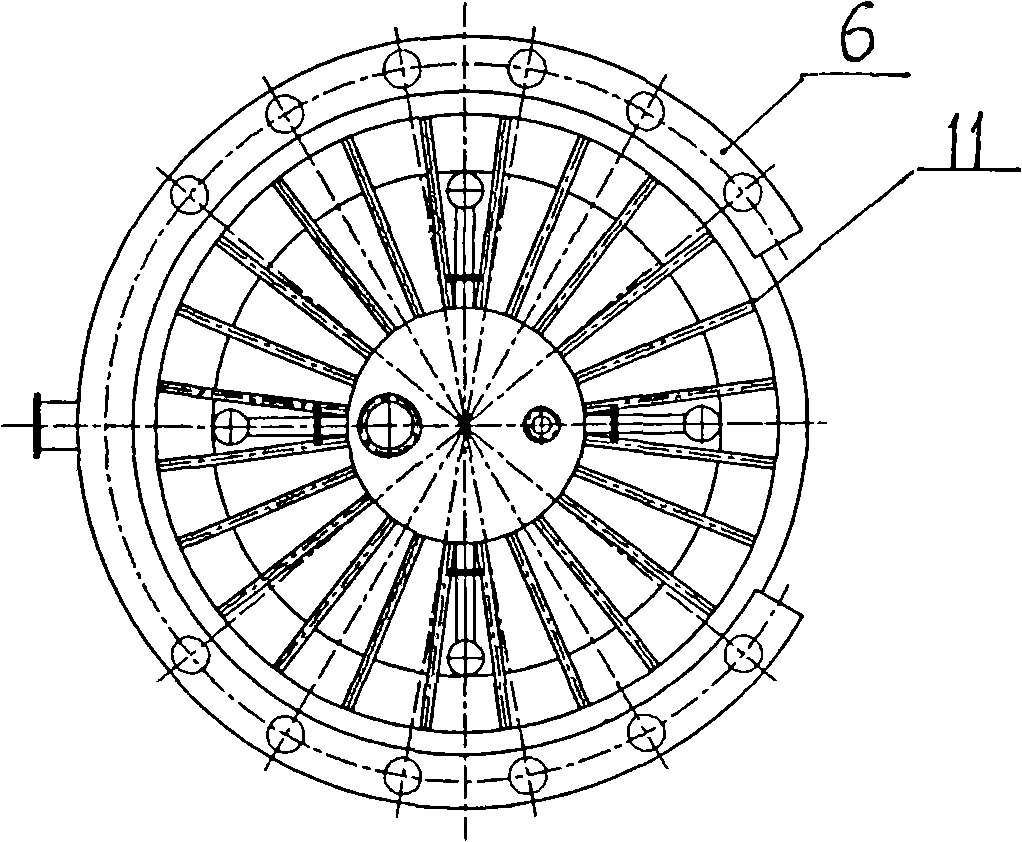

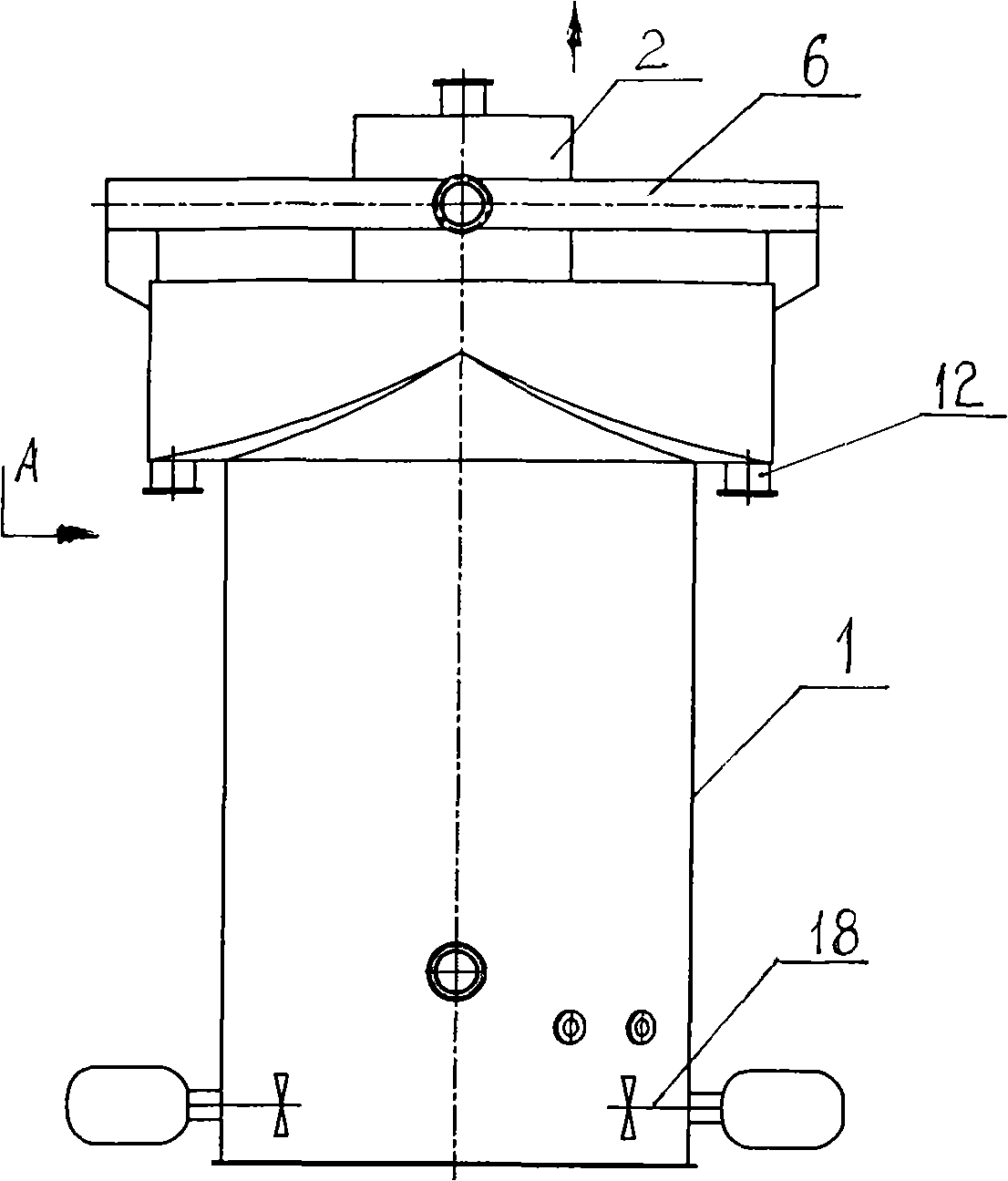

[0066] see figure 1 , figure 2 , image 3 , Figure 4 , the special flotation column for fly ash of the present invention is equipped with a slurry distributor 2 on the top of the flotation column cylinder body 1, and the fly ash slurry is input from here, and then enters the floating column through the gaps of a plurality of umbrella-shaped distribution balanced overflow plates. Inside the column selection cylinder, a multi-layer bubbling plate 3 is arranged in the flotation column cylinder body 1, and the bubbling plate 3 is formed by drilling holes on a flat plate. The flow device 4 is exactly that a plurality of liquid inlet pipes or nozzles are installed obliquely in the same direction on the cylinder body. The bottom of the flotation column body 1 is provided with multi-point tailing ash overflow holes 5 to prevent the tailing ash from blocking the outlet pipe. A slurry distribution pipe 6 is installed around the slurry distributor 2, and a circulating pipeline 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com