Suction head apparatus

A technology of control devices and suction pads, applied in the direction of chucks, manipulators, electrical components, etc., can solve problems such as bulky, complex structures, difficult to meet space saving, intensification and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

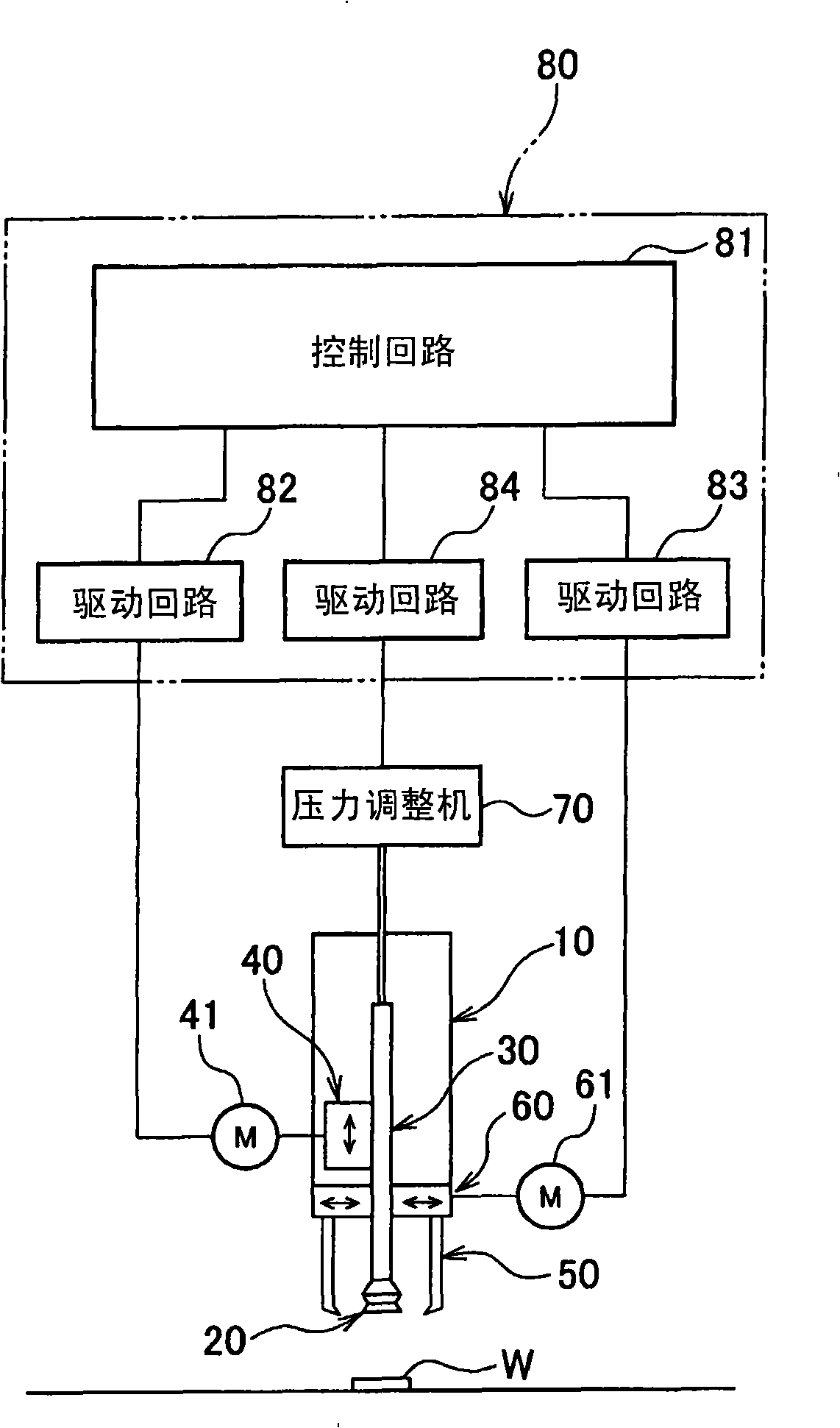

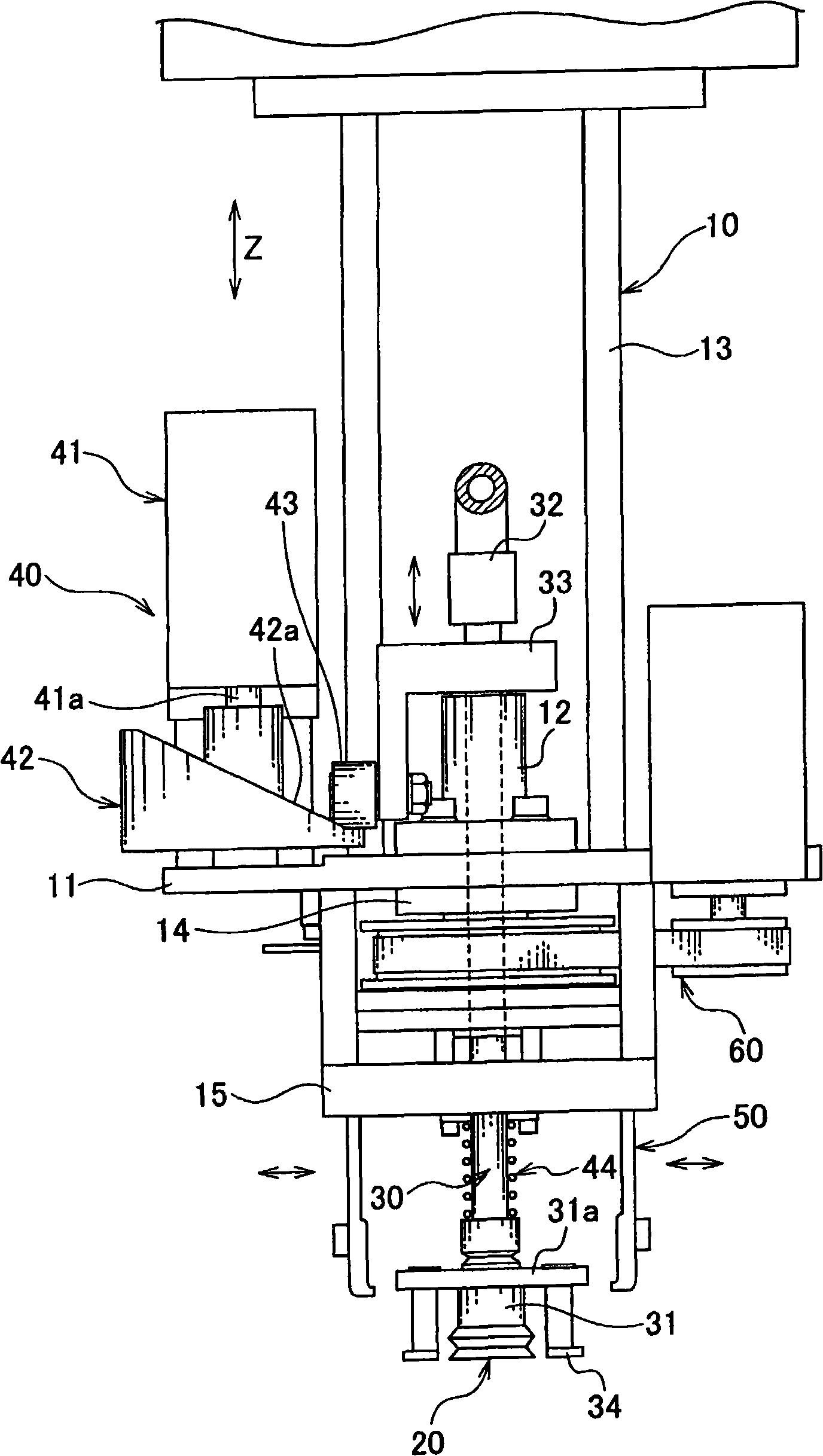

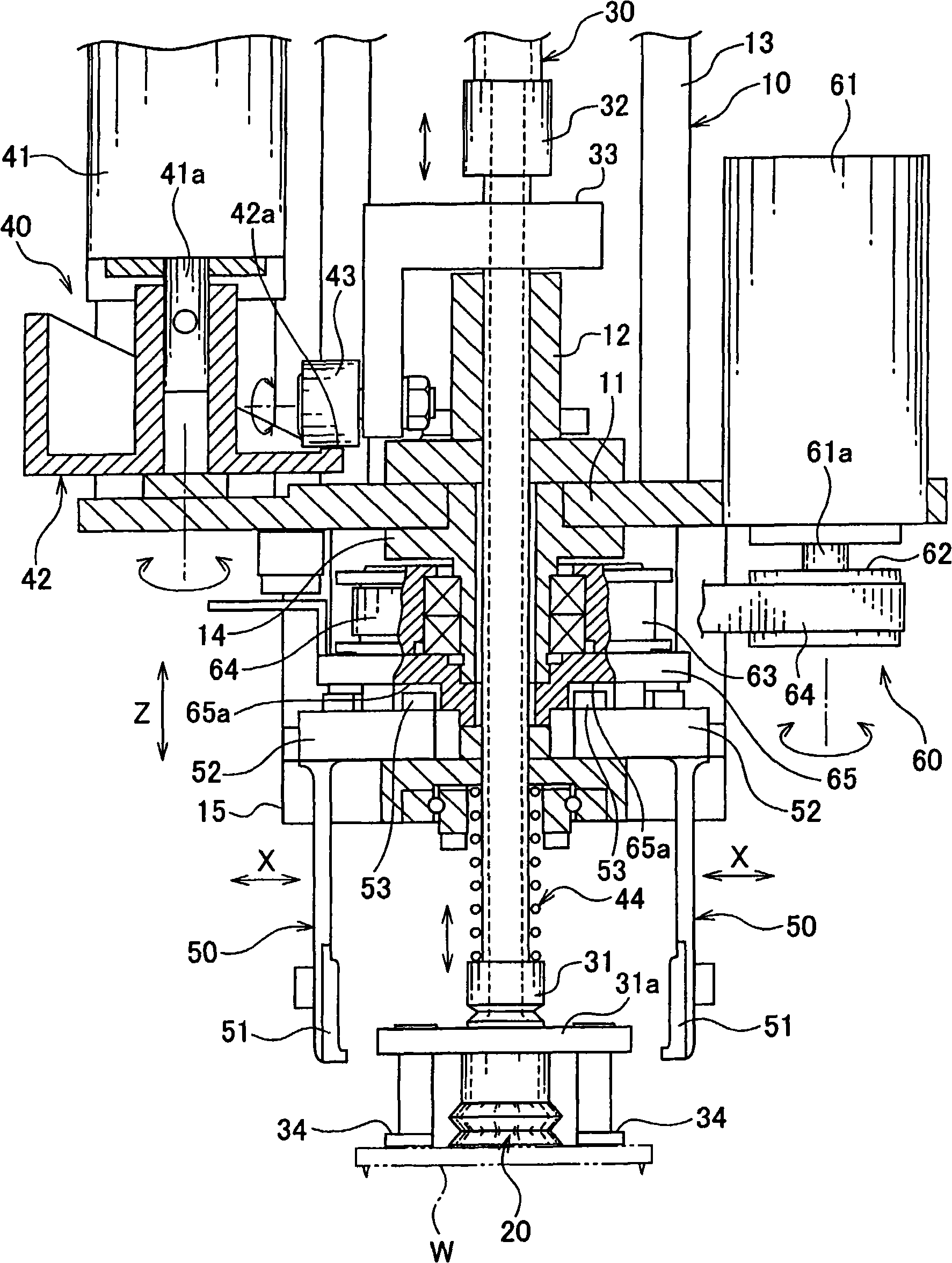

[0037] like Figure 1 to Figure 3As shown, the suction head device includes: a basic frame 10 for the structure; a suction pad 20 for absorbing the workpiece W; a shaft 30 for holding the suction pad 20 at its lower end and moving up and down; a lifting mechanism 40 for lifting the shaft 30; Two pairs of clamping arms 50 and a drive mechanism 60 as a clamping mechanism for clamping the workpiece W absorbed by the suction pad 20 from a substantially horizontal direction; a pressure regulator 70 as a suction generating mechanism for generating suction on the suction pad 20 ; and the control unit 80 etc. as a control device that controls the drive control of the entire device.

[0038] In addition, this suction head device is used as a workpiece transfer device that absorbs a workpiece W conveyed by a conveyor belt and transfers it to a predetermined processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com