Filling and pouring method of intelligent transmitter to measure bellows pressure transmission medium

A technology of intelligent transmitter and conductive medium, which is applied in the direction of using fluid devices to transmit sensing components, etc., can solve the problems of slow speed and affect work efficiency, and achieve the effects of improving work efficiency, ensuring measurement accuracy, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

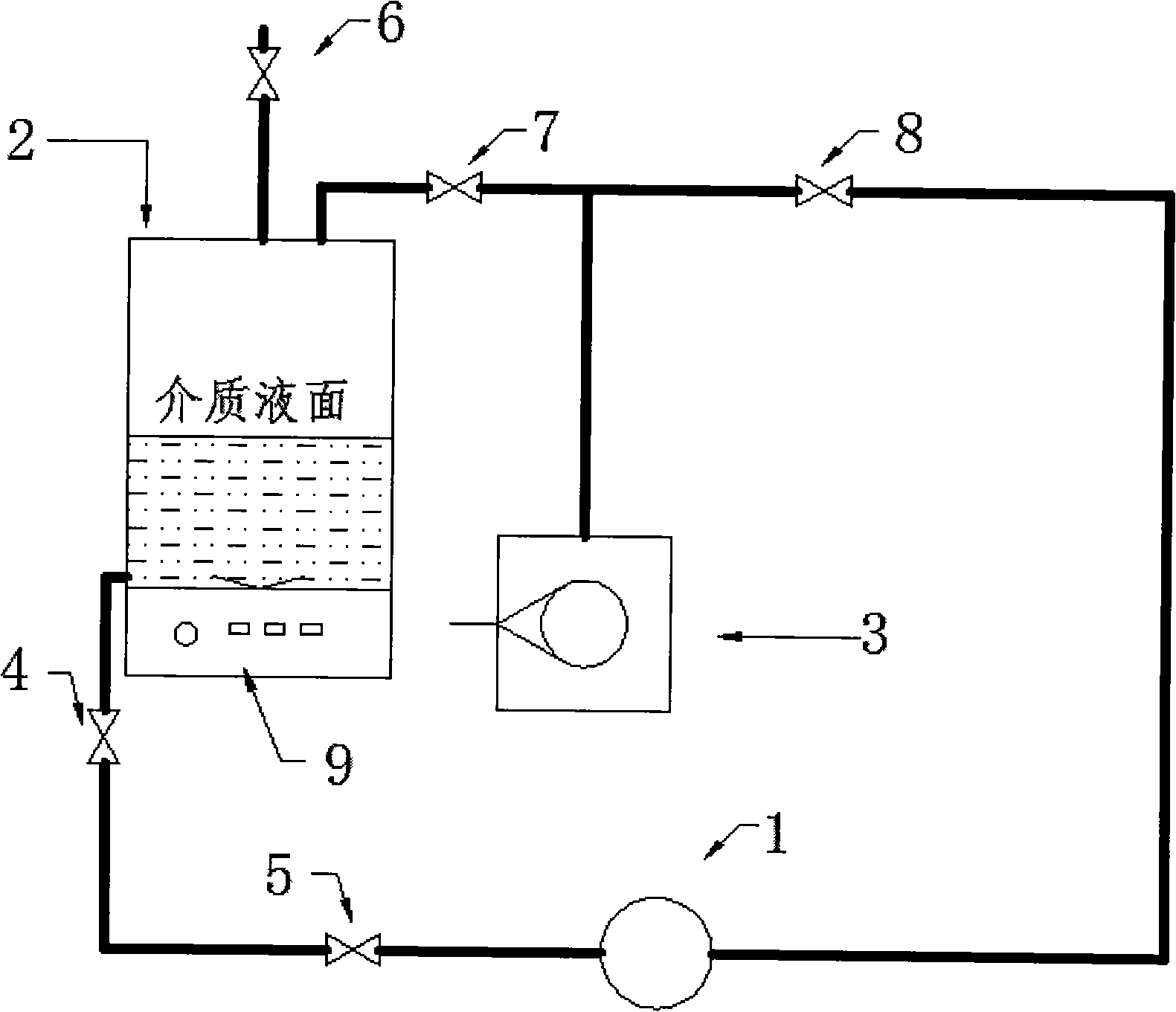

[0020] A kind of filling method of intelligent transmitter measuring bellows pressure transmission medium (see figure 1 ), which includes the following steps:

[0021] ① Before filling starts, close all valves.

[0022] Open the valve II8, and use the RVP-6 vacuum pump 3 produced by Beijing Zhongke Keyi Technology Development Co., Ltd. to vacuum the inside of the flange 1 of the smart transmitter to make the vacuum inside the flange 1 of the smart transmitter reach below 1.33Pa. , in a vacuum state.

[0023] ② Use the H01-1A magnetic heating stirrer 9 produced by Shanghai Meiyingpu Constant Temperature Magnetic Stirrer Factory to stir and heat the signal transmission medium of the flange intelligent transmitter until no bubbles are generated, so that the light components and water in it are evaporated Then open valve I7, take away light component and moisture with vacuum pump 3, make oil tank 2 (volume is 5 liters) internal vacuum degree reach below 1.33Pa, thereby obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com