Method and apparatus for detecting unqualified silk screen printing mark

A technology of screen printing and marking, applied in measuring devices, instruments, etc., can solve the problems of inability to guarantee detection accuracy and low detection efficiency, and achieve the effect of saving time and energy, and improving efficiency and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

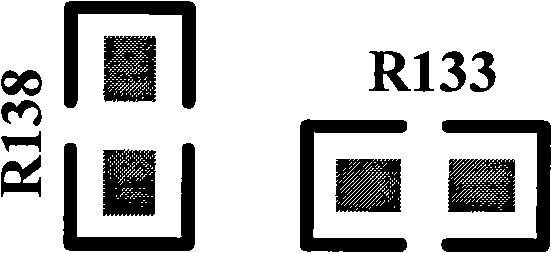

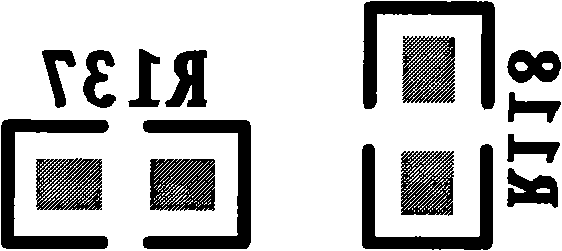

Image

Examples

Embodiment Construction

[0027] Embodiment 1 of the present invention provides a solution for detecting unqualified silk screen marks, which can automatically detect unqualified silk screen marks on the PCB, and solves the problems of low efficiency and low accuracy of manual detection in the prior art.

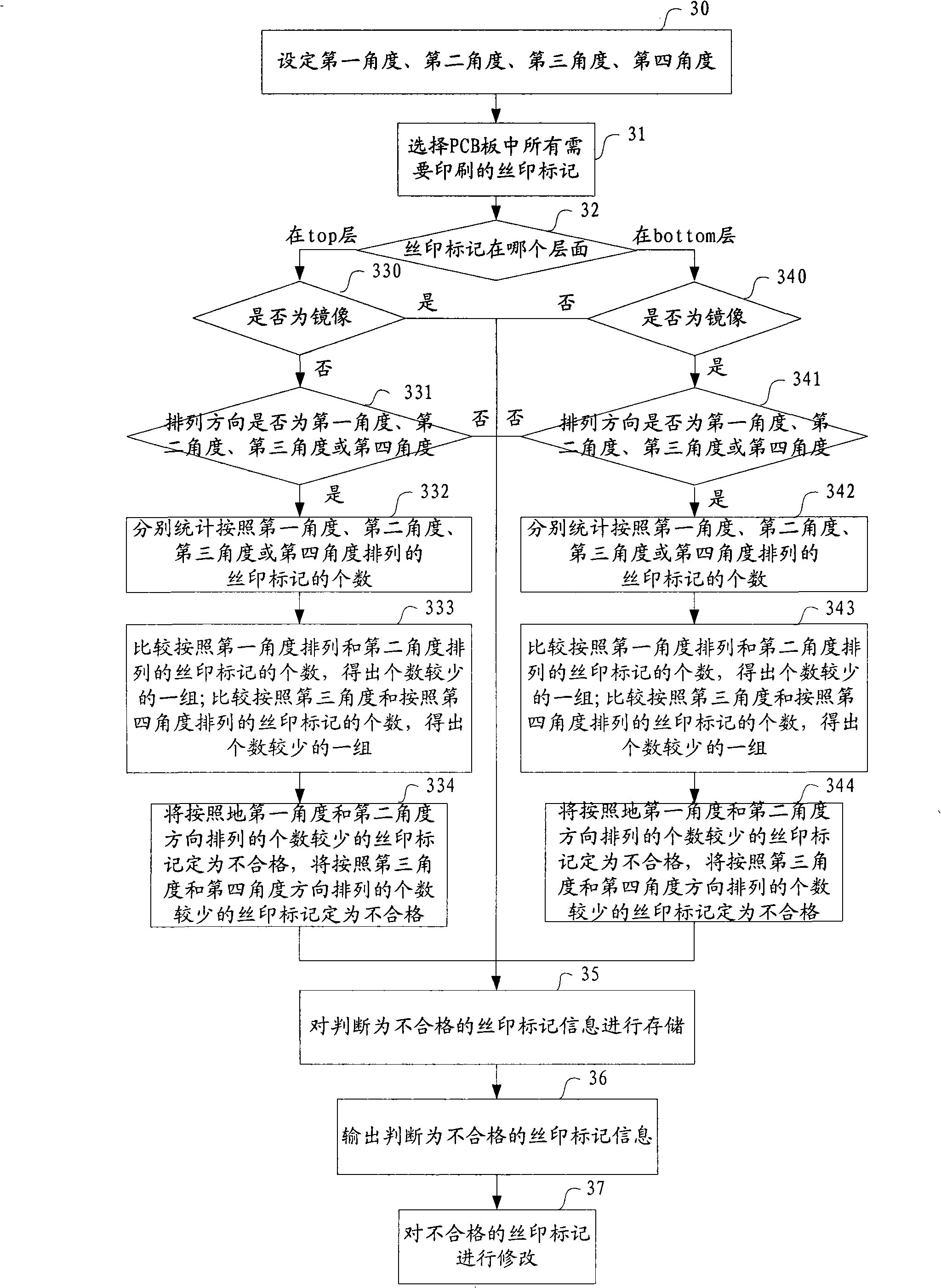

[0028] like image 3 As shown, it is a flow chart of a method for detecting unqualified silk screen marks provided by the present invention. The main implementation principles of the method are as follows:

[0029] Step 30, setting the first angle, the second angle, the third angle, and the fourth angle;

[0030] Wherein, the difference between the third angle and the first angle is 2n+1 (n is an integer) times of 90 degrees; the difference between the second angle and the first angle is 2n+1 (n is an integer) times of 180 degrees; the fourth The difference between the angle and the third angle is 2n+1 (n is an integer) times of 180 degrees. Preferably, for example, the first angle can be 0 degrees...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com