Parallelly-arranged double-circulating heat pump water heater

A technology of heat pump water heater and double circulation, which is applied in the direction of fluid heater, lighting and heating equipment, etc., and can solve the problems of stable operation risk of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

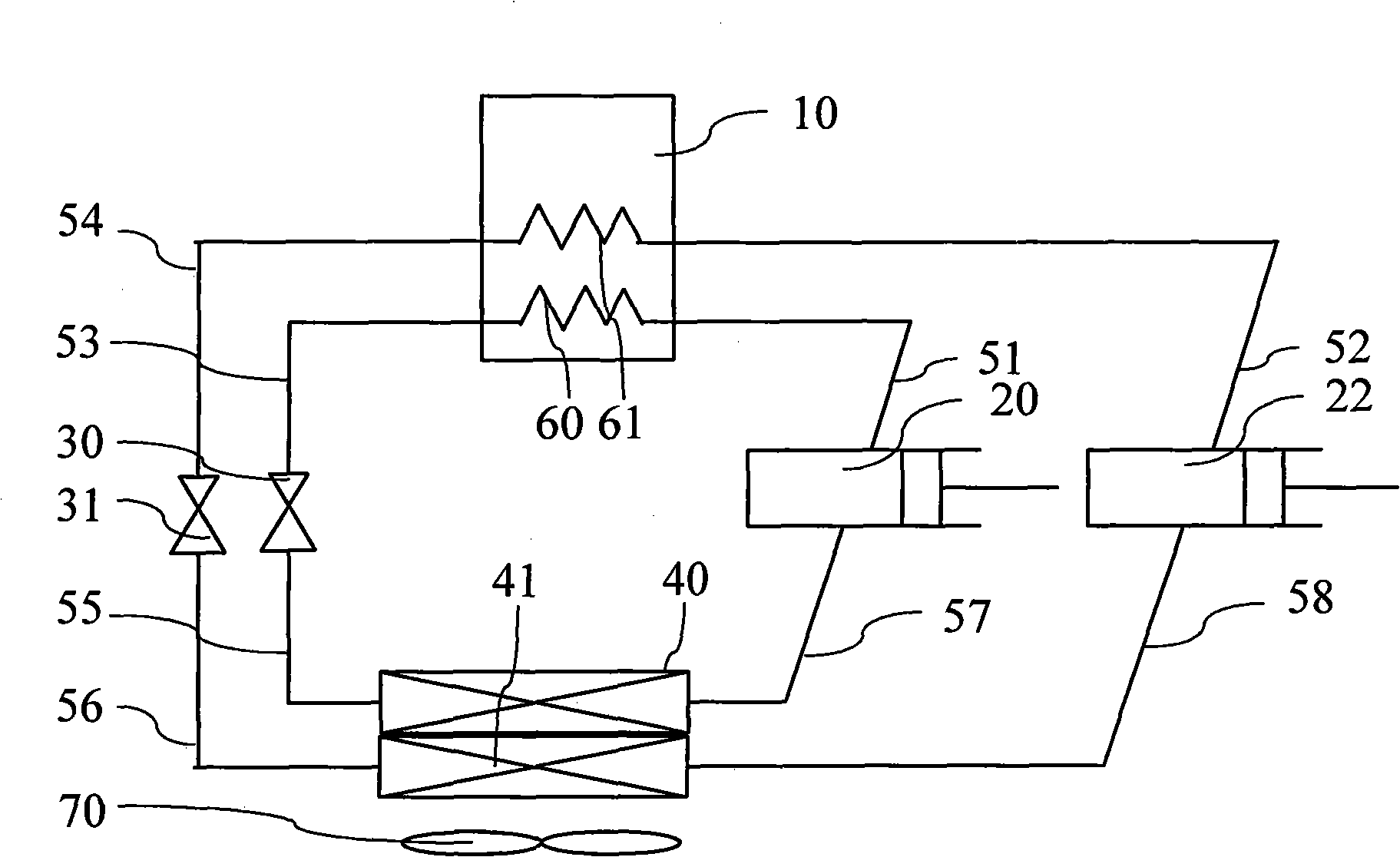

[0018] Example 1, see figure 1 , figure 2 . The parallel double-cycle heat pump water heater of the present invention includes two sets of vapor compression heat pump devices, the outlet of the first compressor 20 is connected to the first radiator 60 through a pipeline 51 , and the inlet of the first compressor 20 is connected to the first evaporator 40 . The first radiator 60 is placed in the water tank 10, the first radiator 60 communicates with the first throttling element 30 through the pipeline 53, and connects the first evaporator 40 through the pipeline 55, and the first evaporator 40 passes through the pipeline 57 Connected to the first compressor 20. The outlet end of the second compressor 22 is connected to the second radiator 61 through the pipeline 52 , and the inlet end of the second compressor 22 is connected to the second evaporator 41 . The second radiator 61 is placed in the water tank 10, the second radiator 61 communicates with the second throttling ele...

Embodiment 2

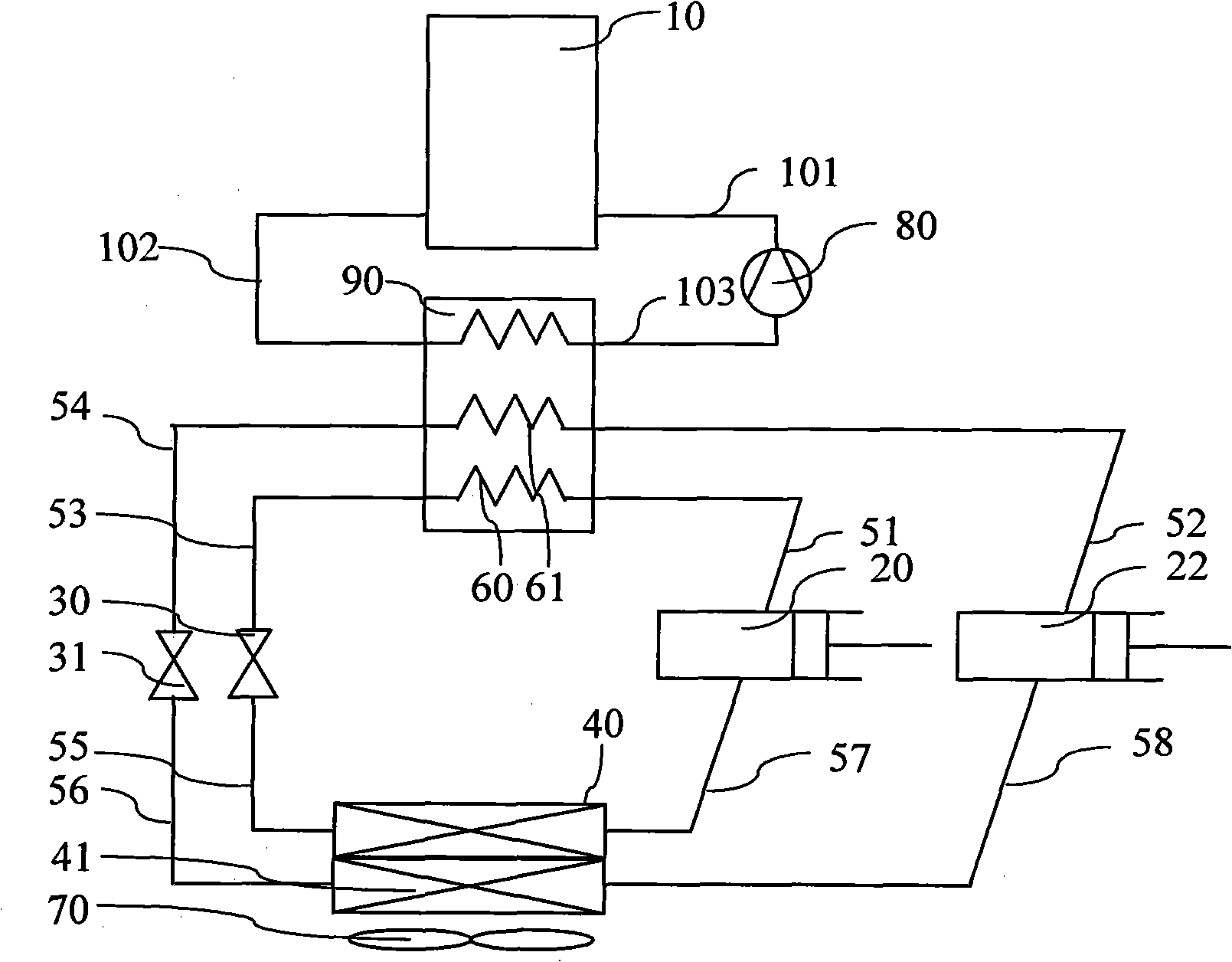

[0022] Example 2, see image 3 , Figure 4 . The parallel double-cycle heat pump water heater of the present invention includes two sets of vapor compression heat pump devices, the two sets of devices act in parallel, the outlet end of the first compressor 20 is connected to the first radiator 60 through a pipeline 51, and the inlet end of the first compressor 20 Connect the first evaporator 40, the outlet end of the second compressor 22 is connected to the second radiator 61 through the pipeline 52, the inlet end of the second compressor 22 is connected to the second evaporator 41, the first radiator 60, the second radiator The radiators 61 are all placed in the indirect heat exchanger 90, the water tank 10 forms a closed circulating water circuit through the indirect heat exchanger 90, the circulating water pump 80, and the pipelines 101, 102, 103, and the first radiator 60 and the second radiator 61 are in the The indirect heat exchanger 90 realizes heat exchange with the...

Embodiment 3

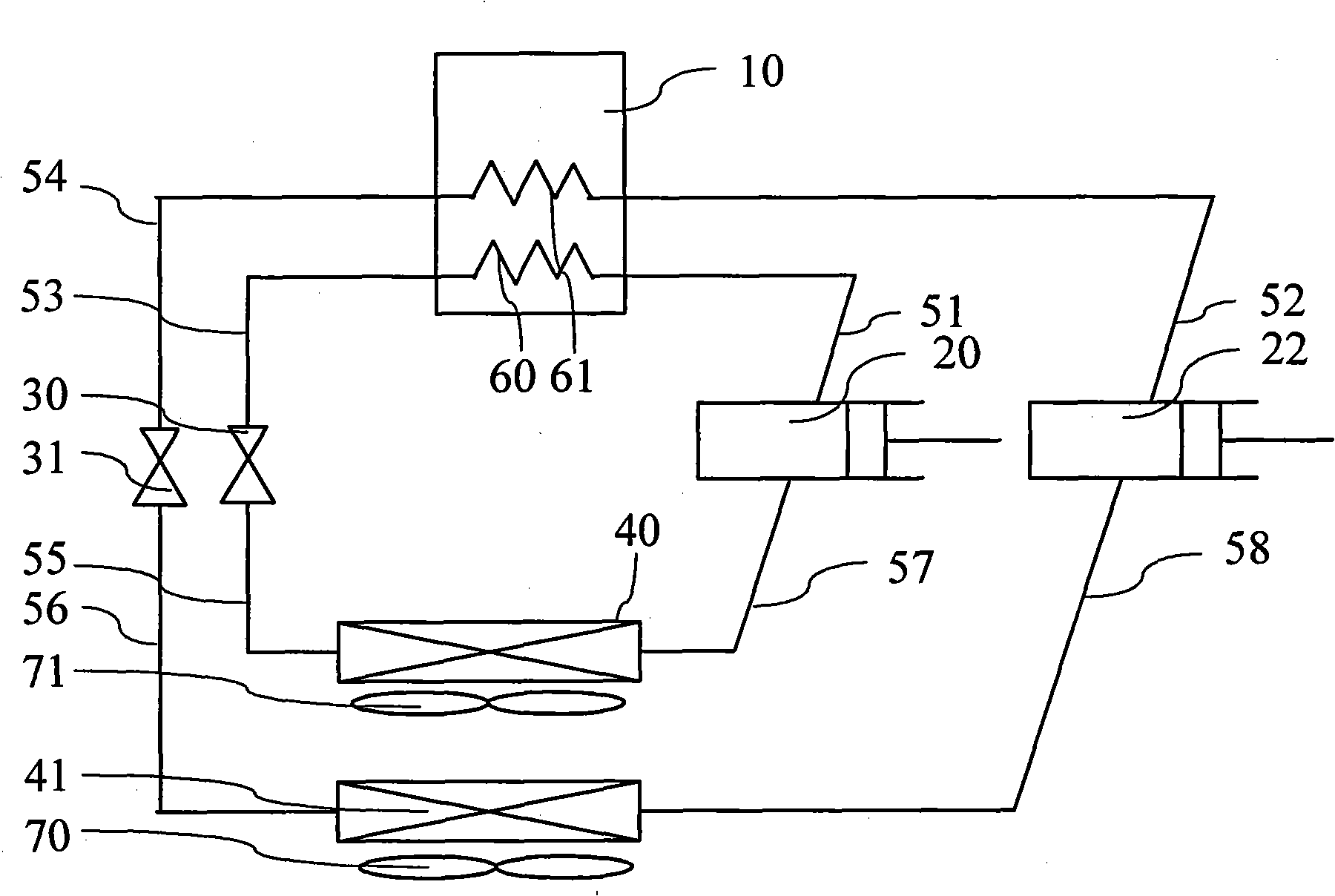

[0025] Example 3, see Figure 5 , Figure 6 . The parallel double-cycle heat pump water heater of the present invention includes two groups of vapor compression devices, and the two groups of devices are connected in parallel. The end is connected to the first evaporator 40, the outlet end of the second compressor 22 is connected to the second radiator 61 through the pipeline 52, the inlet end of the second compressor 22 is connected to the second evaporator 41, the first radiator 60 and the second The radiators 61 are all placed in the water tank 10, and the tap water passes through the circulating radiator 63 to exchange heat with the water in the water tank 10. The first radiator 60 communicates with the first throttling element 30 through the pipeline 53, and through the pipeline 55 The first evaporator 40 is connected, and the first evaporator 40 is connected with the first compressor 20 through a pipeline 57 . The second radiator 61 communicates with the second thrott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com