1000MW steam turbine distorting yataghan blade as well as method for manufacturing the same

A technology of steam turbines and sabers, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of large secondary flow loss, etc., achieve the effects of reducing mold loss, reasonable process flow, and guaranteed yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

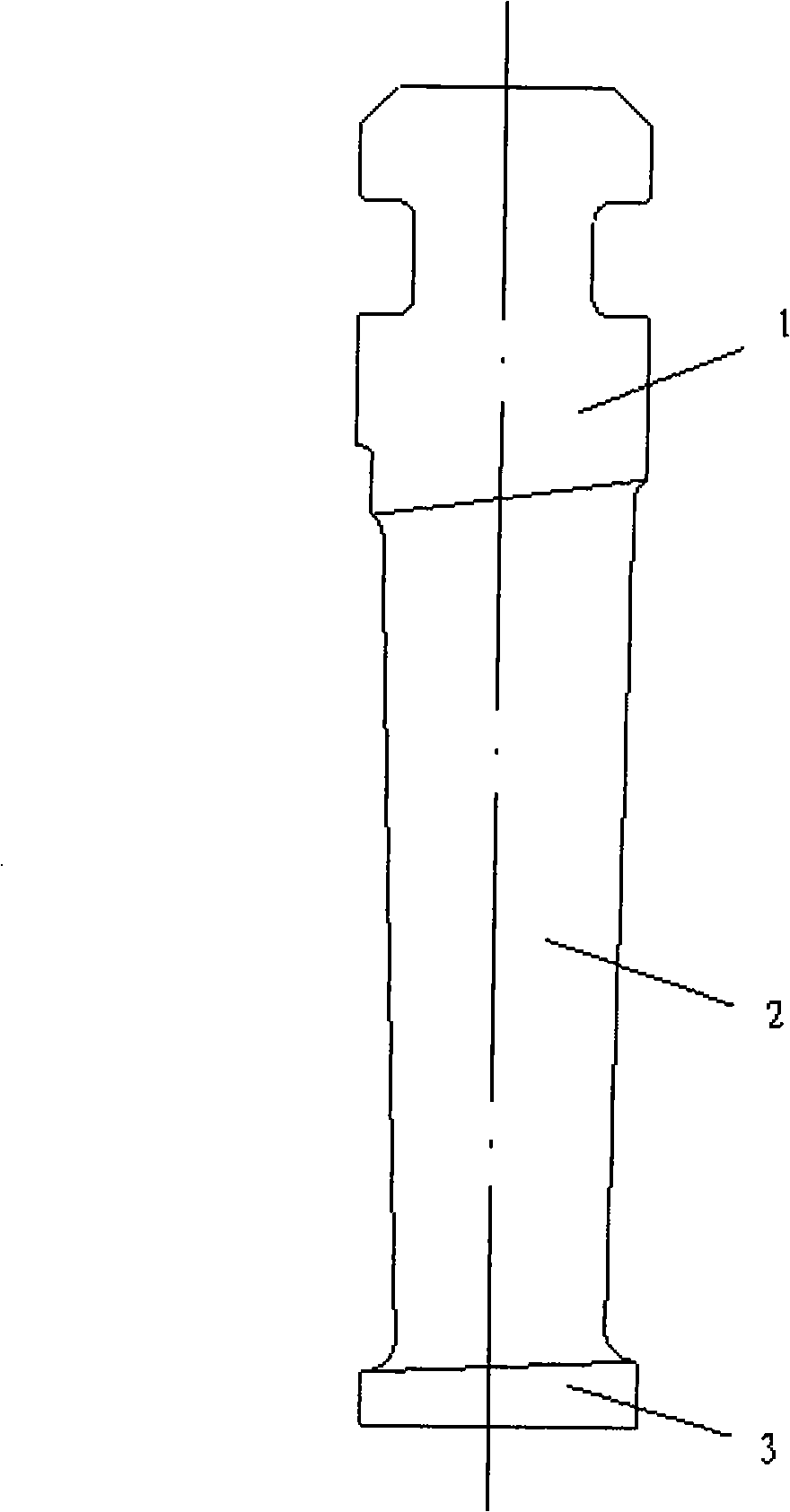

[0023] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. This kind of 1000MW ultra-supercritical steam turbine high, medium and low pressure cylinder twisted saber-shaped stationary blades, its form is composed of three parts: blade root 1, blade shape 2, shroud 3 (see image 3 , Figure 4 , Figure 5 ).

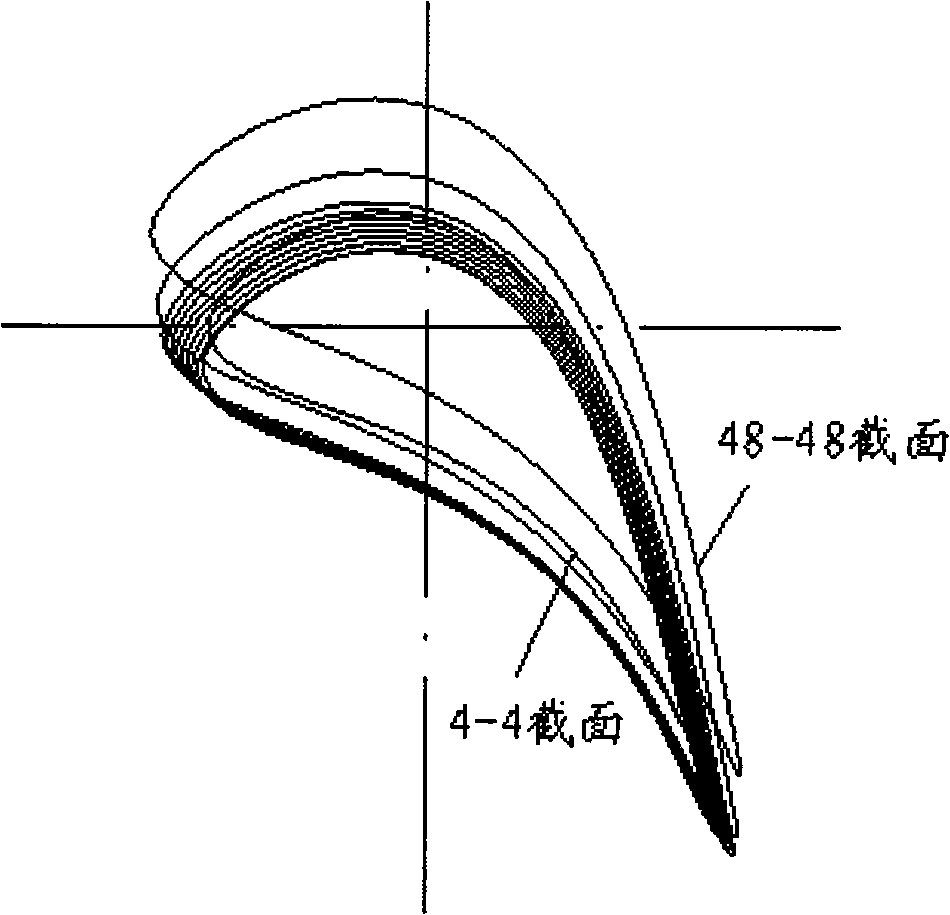

[0024] see figure 1 , figure 2 , Figure 4 On the basis of the original variable-section twisted blade, this kind of stator blade type 2 is bent in a certain circumferential direction, and its form is about 16° at the top and about 12° at the root. See the throat stack in Table 1 for details. The change of point coordinates in the Y direction. When the blade is formed, it can be translated along the circumferential direction on the corresponding blade height according to each section profile of the original straight blade or twisted blade. from figure 1 , Figure 4 It can clearly see the bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com