Buckle oil manifold thread buckle spray sand guarding thread

A technology for fastening oil pipes and protective wires, which is applied in the direction of drill pipes, casings, coatings, etc., and can solve the problems of thread tightness and anti-corrosion effects, and achieve the effect of solving sealing and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

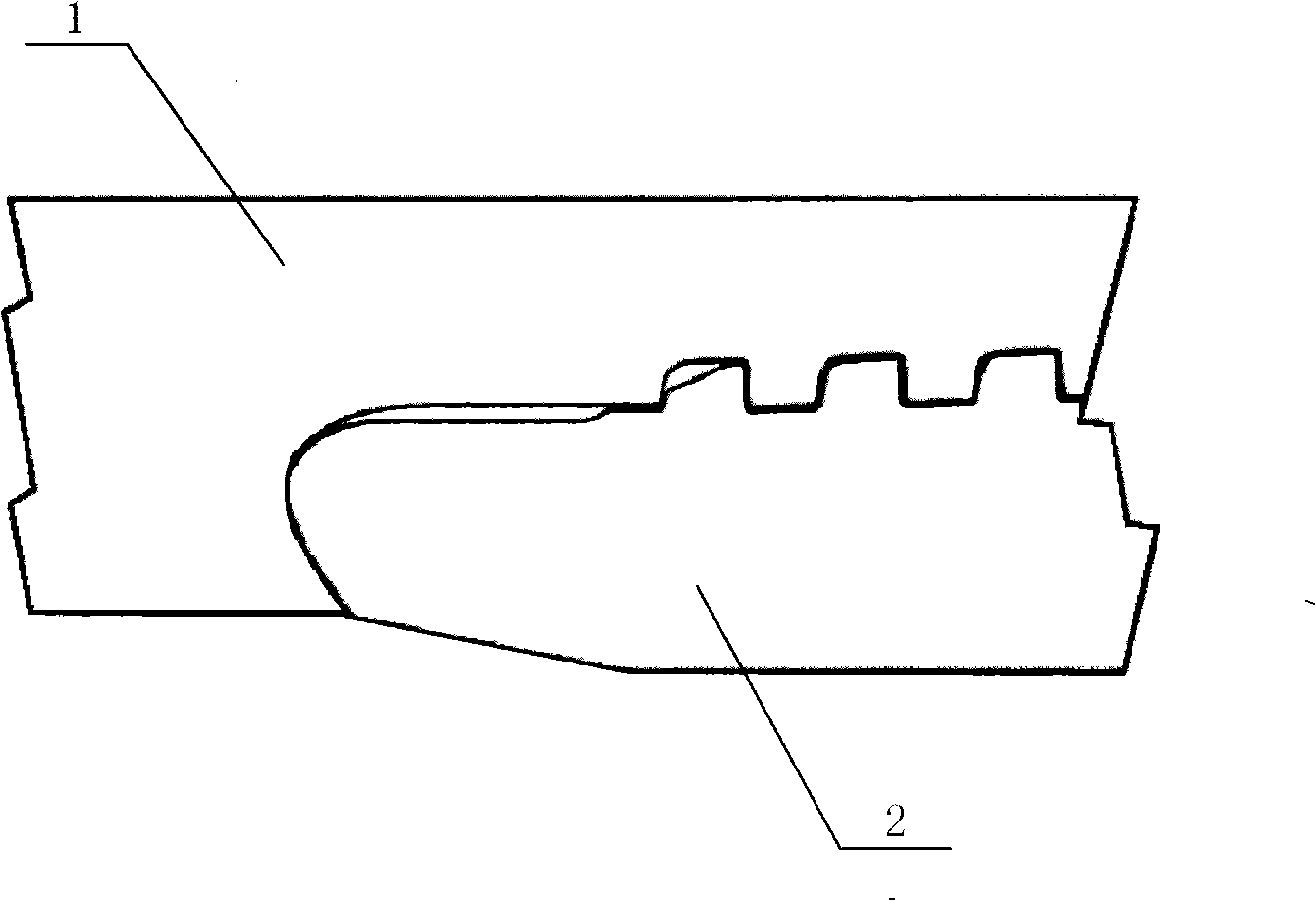

[0011] The invention provides a sandblasting protective wire for oil pipe threading. The protective wire is casted at one time by using the oil pipe coupling as a mold. The protective wire 2 is closely matched with the oil pipe thread 1. The material of the protective wire 2 is Synthetic rubber of a certain hardness. When the protective wire 2 is tightened, the front end of the synthetic rubber protective wire is closely attached to the sealing protection part, forming a sealing protection for the area and the internal thread, which realizes the protection of the sealing end face and avoids damage to the wire during sandblasting. Damage to buckles and sealing surfaces.

[0012] The invention solves the sealing and anti-corrosion problems of the threaded thread of the pipe and the sealing surface, and increases the service life of the threaded t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com