One-step method for preparing dihydroxy acetone by dioxygen catalytic oxidation of glycerol

A technology of dihydroxyacetone and glycerin, which is applied in the field of one-step preparation of dihydroxyacetone from glycerol through molecular oxygen catalytic oxidation, can solve the problems of harsh living conditions, inability to realize localization, and no research report, etc., and achieves small environmental impact and easy The effect of low promotion and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

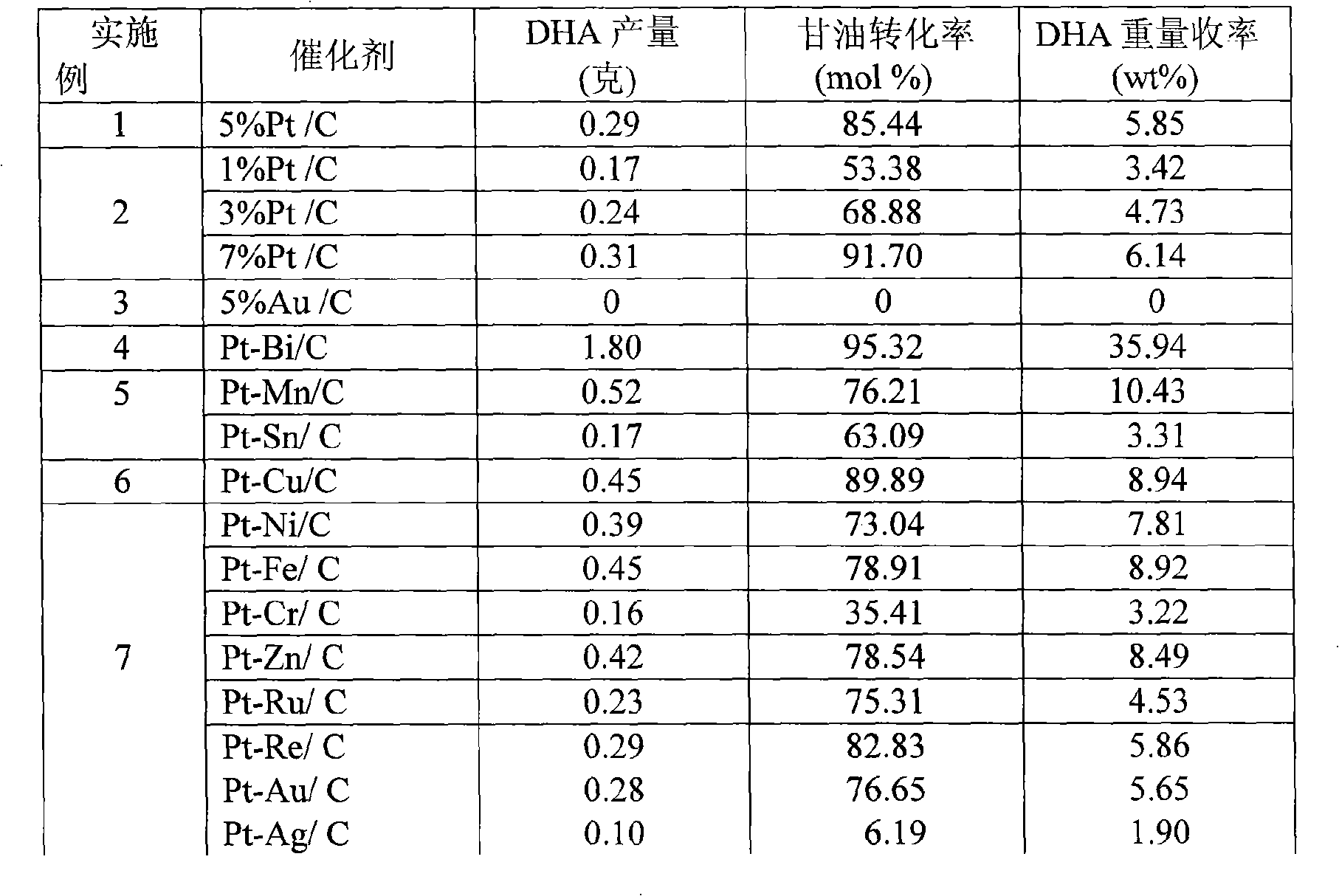

[0024] Example 1. Disperse 5g of activated carbon in 75ml of water, then slowly add a certain concentration of chloroplatinic acid solution dropwise to the above suspension, control the metal load to 5wt%, and stir and impregnate at 50°C for 3.5h , and then under the condition of 50° C., add a certain amount of formaldehyde, control the molar ratio of formaldehyde and metal to about 15:1, and control the pH of the solution during the reduction process at about 8, and stir for 1 hour. It was then filtered, washed several times with deionized water, and dried under vacuum at 60 °C to obtain a 5% Pt / C catalyst.

[0025] Add 0.5 g of Pt / C catalyst into a 100 ml three-necked flask, accurately weigh 5.0 g of glycerol, dilute it with deionized water and transfer it into a three-necked flask, the total volume of the reaction solution is about 50 ml. The temperature of the water bath was raised to 60° C., and oxygen gas was introduced under magnetic stirring for bubbling, and the flow ...

Embodiment 2

[0026] Embodiment 2, using activated carbon as a carrier, adopting chloroplatinic acid as a precursor, controlling the load of metal Pt to be 1wt%, 3wt%, and 7wt%, respectively, the metal loading method and glycerol catalytic reaction conditions are the same as in Example 1. The results are summarized in Table 1.

Embodiment 3

[0027] Embodiment 3, using activated carbon as a carrier, using chloroauric acid as a precursor, controlling the loading of metal Au to 5 wt%, the metal loading method and glycerol catalytic reaction conditions are the same as in Example 1. The results are shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com