Circular press dewatering method

A press dehydration and press roll technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of dehydration treatment output reduction, affecting dehydration efficiency, and material volume reduction, so as to improve the effect and output, high dryness, The effect of improving dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

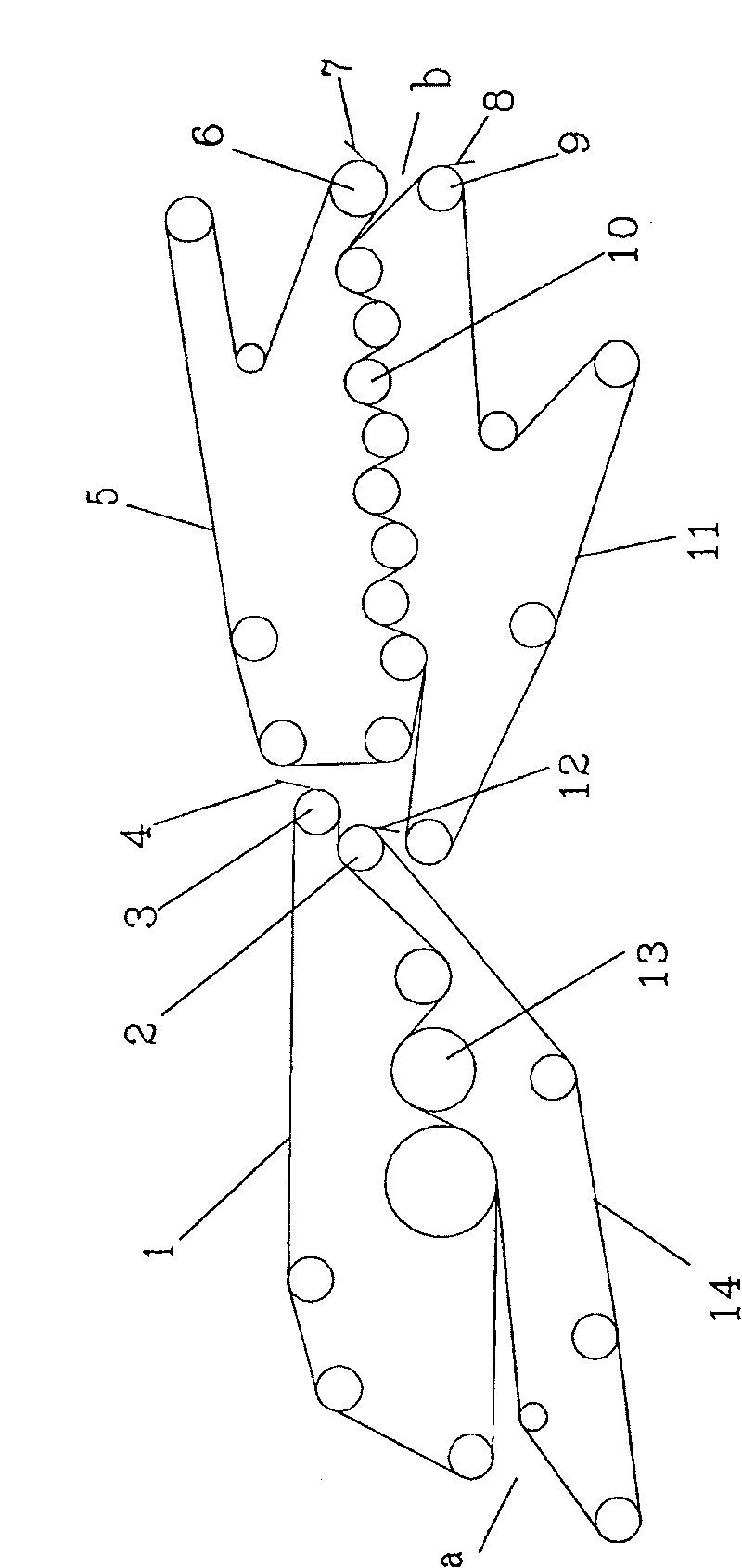

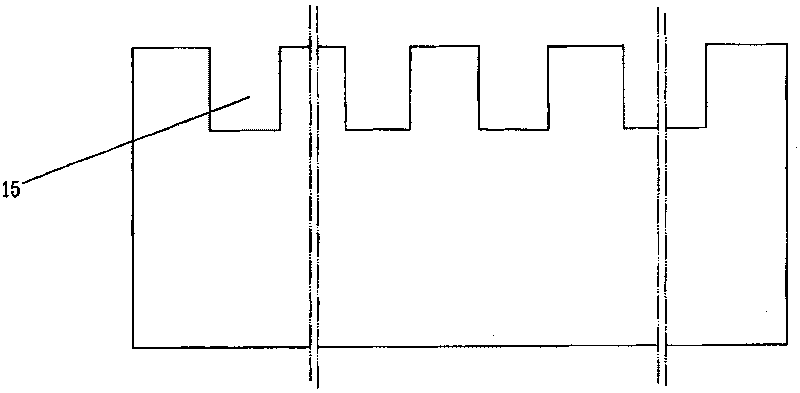

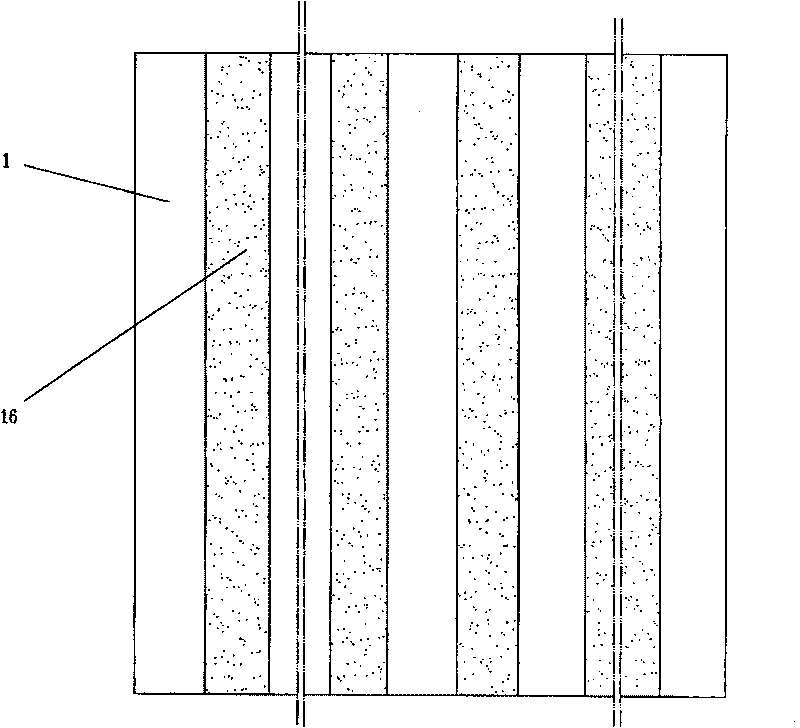

[0015] The circulating press dehydration method is a mechanical press dehydration method. The dehydrated material is wrapped in the upper and lower filter belts wrapped around the press roll in the press dewatering area of the press dehydration equipment, and is subjected to the press roll and filter. Dehydration with a press. The press dehydration method performs circular press dehydration on part of the dehydrated materials, uses the dehydrated materials to adjust the moisture content of the undehydrated materials and improves the dehydration environment, solves the problem of mud running in the prior art, and improves the press dehydration effect and output. Two discharge scrapers are installed at the outlet of the press dehydration zone adopting the circulating press dehydration method of the present invention, one of which is a discharge scraper with a toothed notch, the discharge scraper is installed beside the upper filter belt, and the discharge scraper The notched s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com