Integral tension, relaxation system and technique for pre-tensioned prestressing tension technique

An overall tensioning and prestressing technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of excessive difference in elongation, long stretching time, waste of steel strands, etc., to increase safety factor, elongation The value difference is small and the effect of increasing the speed of prefabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

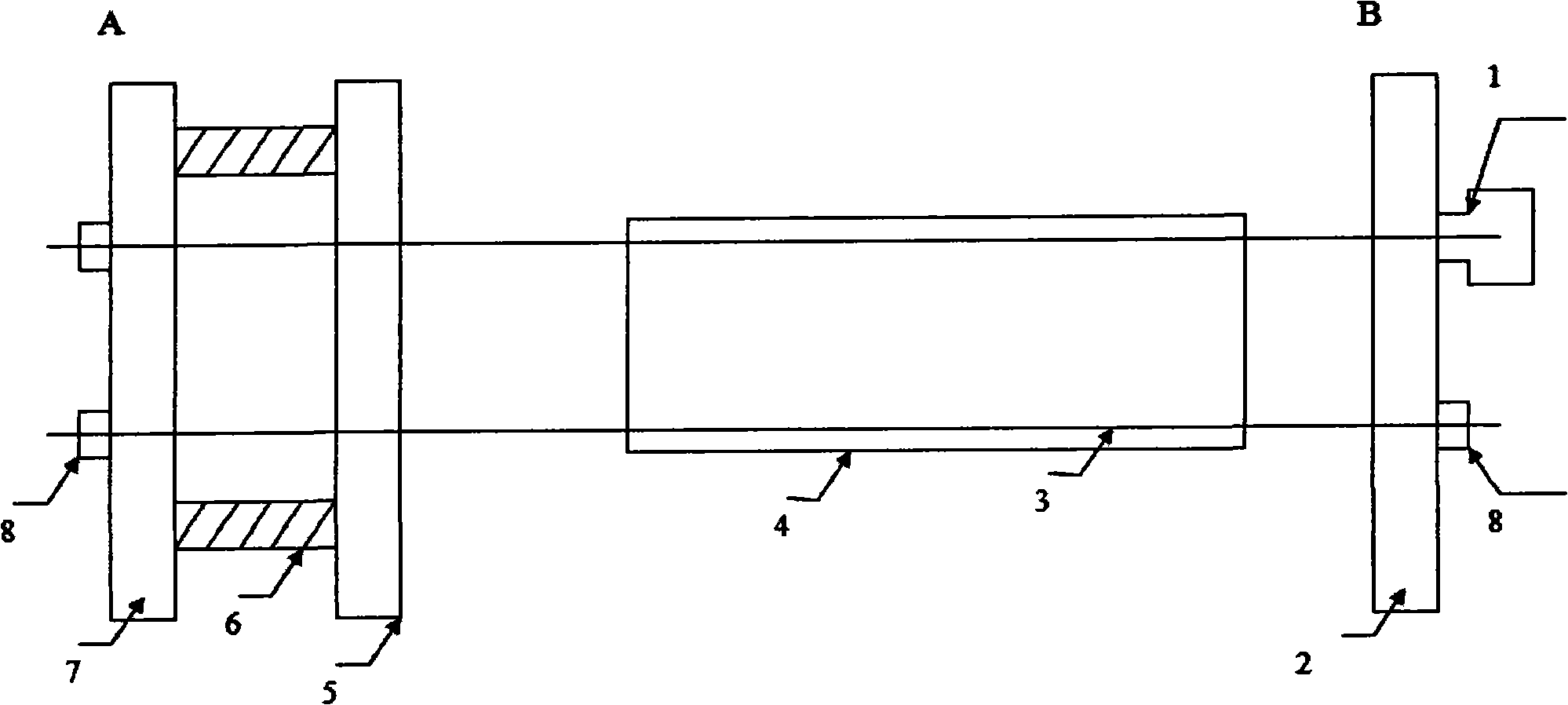

[0041] figure 1 It is a structural schematic diagram of the existing single tensioning and sand box tensioning system. It consists of 1. jack, 2. fixed beam at tension end, 3. steel strand, 4. prefabricated pedestal, 5. fixed beam at passive end, 6. sand box, 7. mobile beam, 8. anchorage.

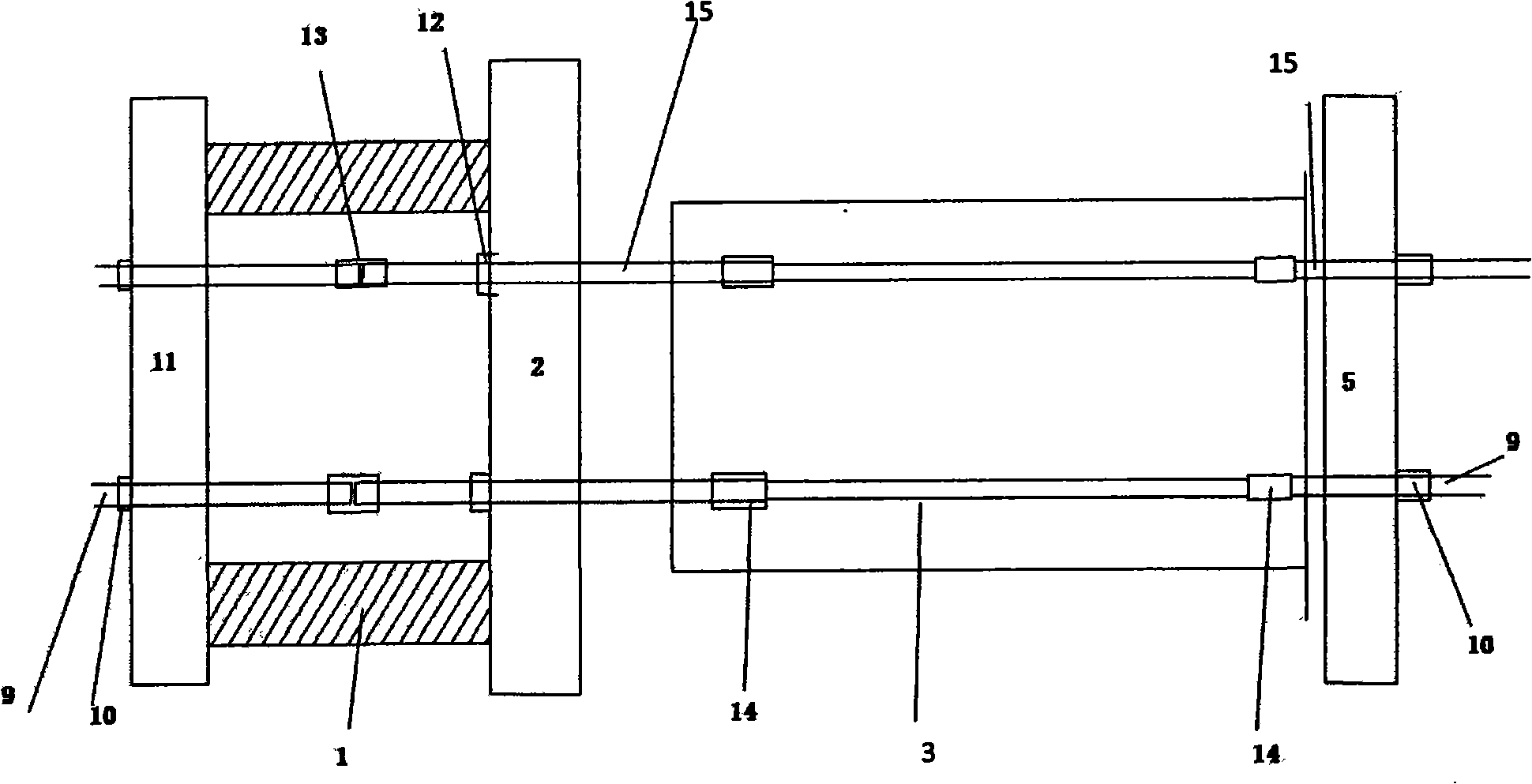

[0042] figure 2 Among them, the present invention includes a fixed beam 5 at the passive end, a prefabricated pedestal 4, a fixed beam 2 at the tensioning end, and a movable beam 11. A pair of jacks 1 are arranged between the fixed beam 2 at the tensioning end and the movable beam 11. Spiral steel tool pull rod 9, the precision-rolled spiral steel tool pull rod 9 is connected with the corresponding work pull rod 15 through the corresponding work pull rod and the tool pull rod connector 13, and the work pull rod 15 is connected with the corresponding steel strand-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com