Modified type polishing pad regulating apparatus technique

A polishing pad and regulator technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of polishing pad surface wear and shortening the service life of the polishing pad, so as to prolong the service life and avoid micro The effect of abrasion and shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The improved pad conditioner process of the present invention will be described in further detail below.

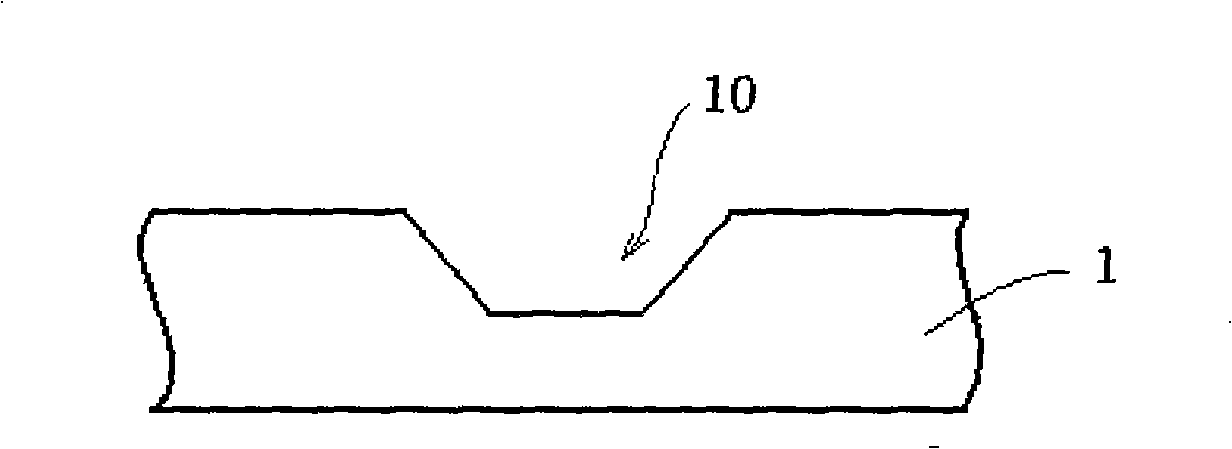

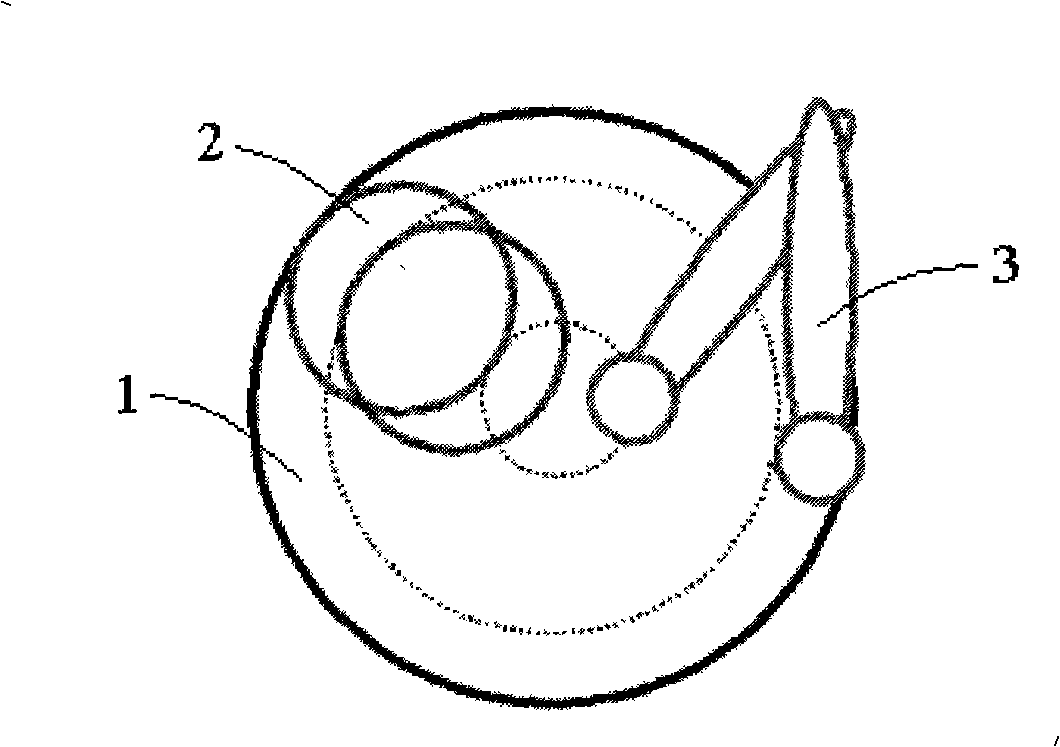

[0016] The improved polishing pad conditioner technique of the present invention firstly adopts high pressure (high down force) to wash and repair the polishing pad surface, to remove the polishing liquid crystallized matter remaining in the groove of the polishing pad surface, prevent the groove from clogging and make the polishing pad flat , can also prevent micro-scratches on the wafer surface during polishing. In this step, the initial position of the polishing pad adjuster can be set at a position of 1.4 to 1.6 inches from the center of the polishing pad, so that the working range of the polishing pad adjuster can be expanded to better remove the polishing pad center area. liquid crystal, and ensure that it does not collide with the polishing head during the movement. Preferably, the distance may be set at 1.4 inches.

[0017] After the high pressure flushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com