Cylinder cap air valve spring cover, locking plate press-loading head

A valve spring and valve lock plate technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large influence of the assembly quality workpiece itself, low efficiency, unstable assembly quality, etc., to ensure the assembly quality. Quality, easy installation and adjustment, stable and reliable equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

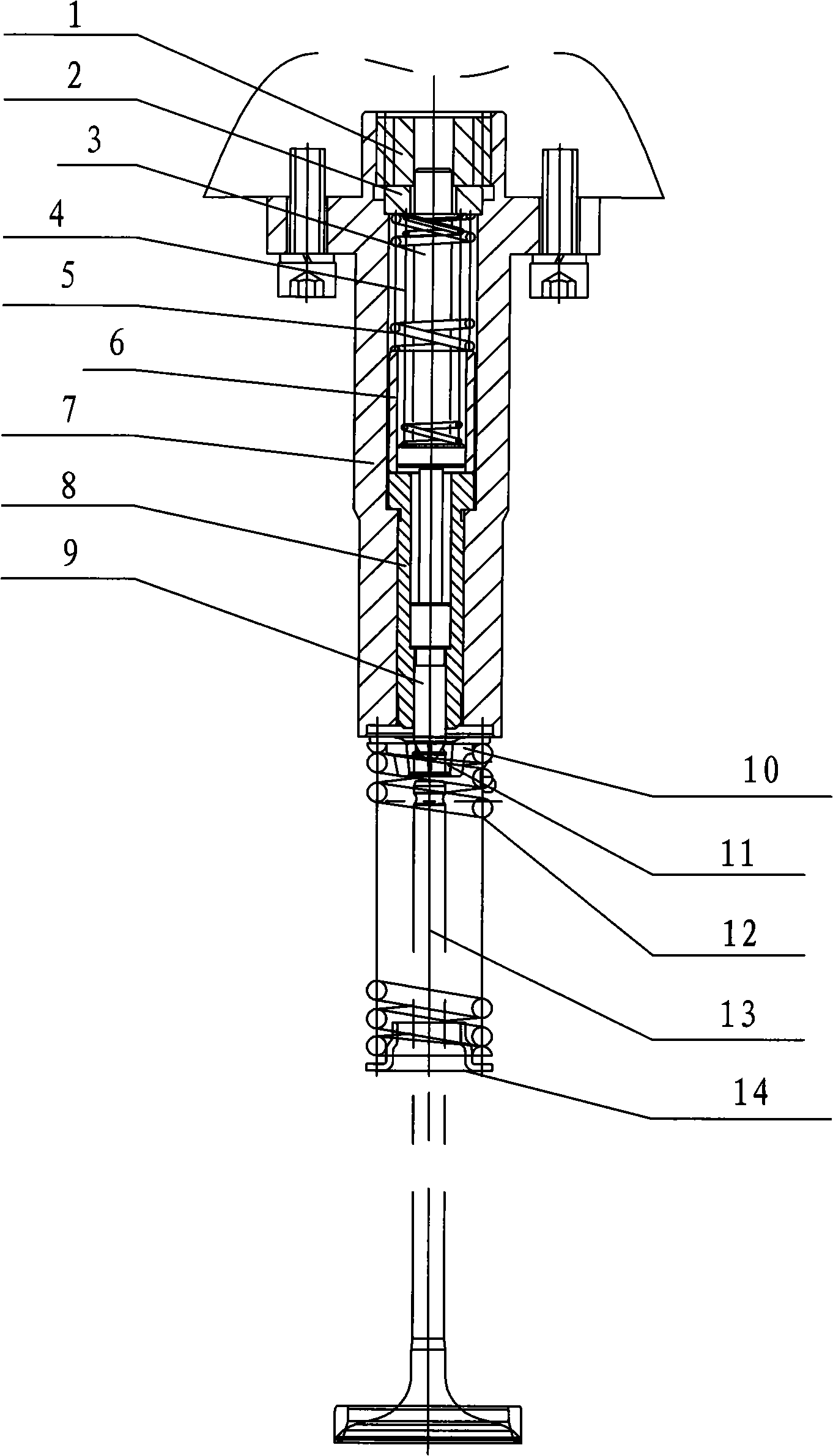

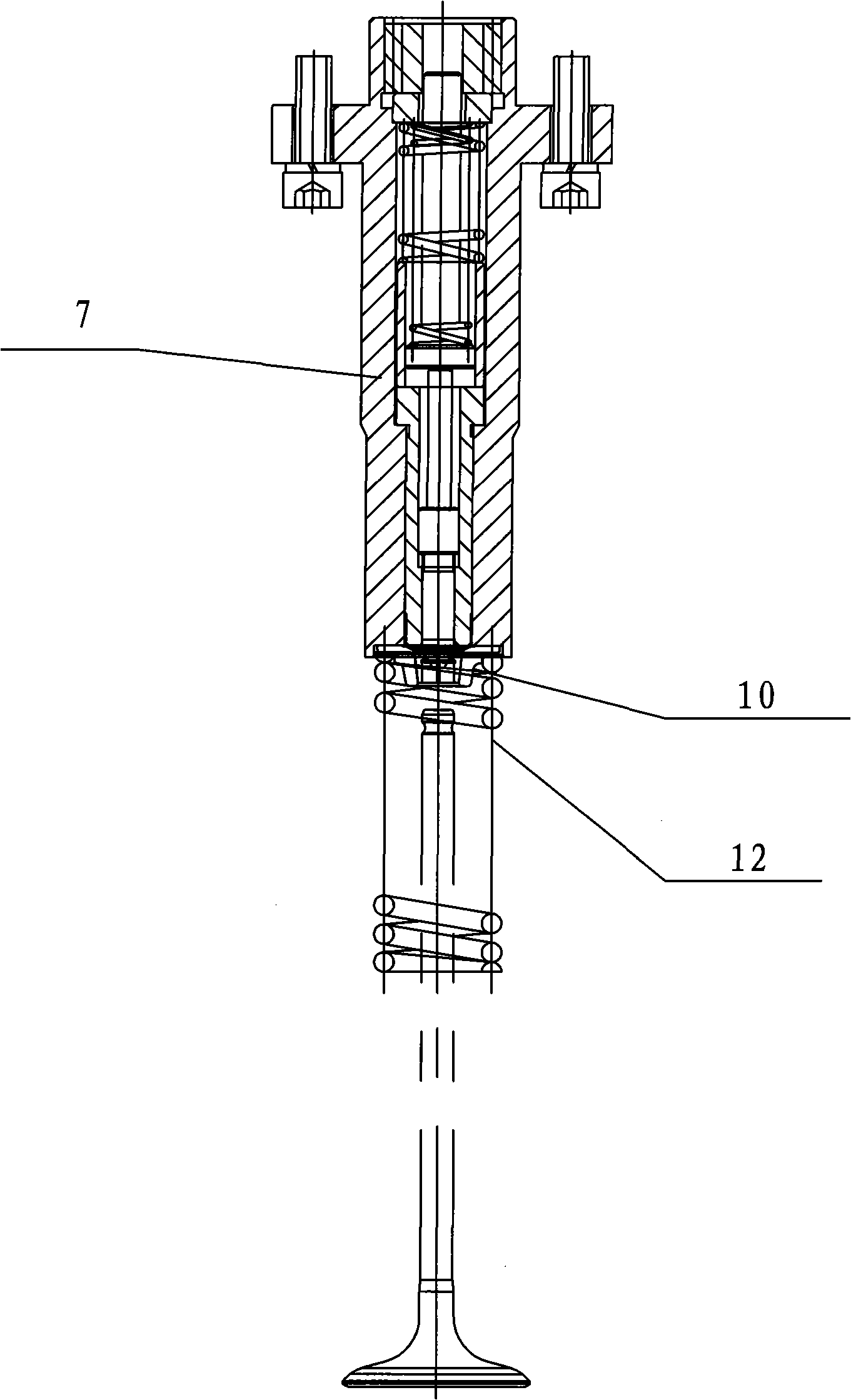

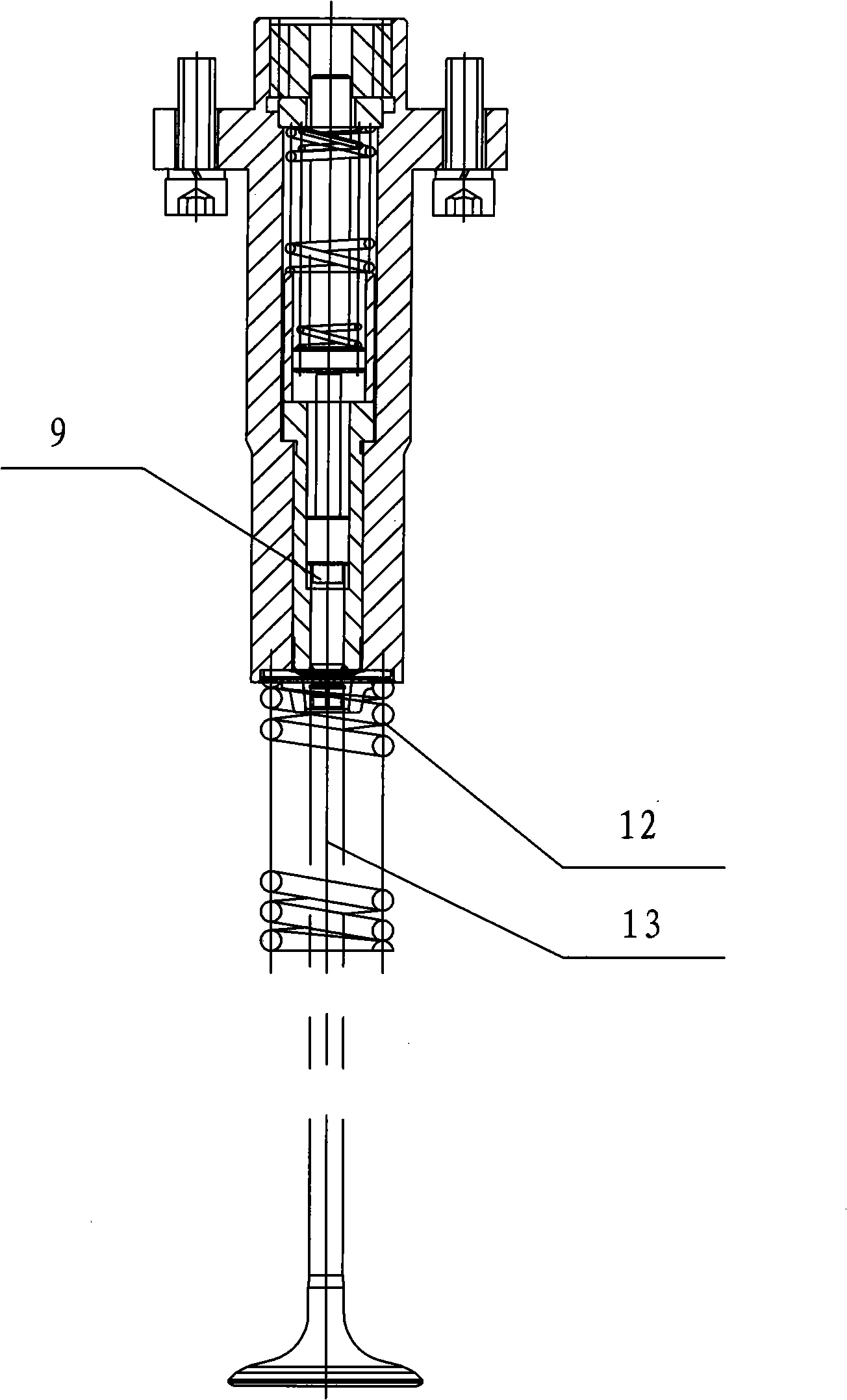

[0021] Such as Figure 1-Figure 7 As shown, a cylinder head valve spring cover, lock plate pressing head, including: compression screw plug 1, spring cover 2, ejector rod 3, inner ring spring 4, outer ring spring 5, sleeve 6, pressure head jacket 7. The core sheath 8 and the indenter core 9; it is characterized in that there is a through hole in the middle of the indenter jacket 7, in which the ejector rod 3 and the indenter core 9 are installed, and the two are freely connected; the ejector rod 3 An inner spring 4 and an outer spring 5 are installed on the top, and a spring gland 2 is arranged on the inner and outer springs, and the spring gland 2 is set on the push rod 3, and the compression screw plug 1 and the pressure head The jacket 7 is threadedly connected; a core sheath 8 is also provided between the pressure head core body 9 and the pressure head jacket 7; there are related valve spring covers 10, valve lock plates 11, and valves under the core sheath. Spring 12, va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com