Ultrasonic flexural vibration device

A bending vibration and ultrasonic technology, applied in the direction of fluid, solid separation, filter screen, etc. using vibration, can solve the problems of unable to increase the power of the transducer, limit the ultrasonic cleaning function, hinder the application of ultrasonic technology, etc., so as to reduce the loosening phenomenon. , The effect of widening the ultrasonic working frequency band and increasing the power application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

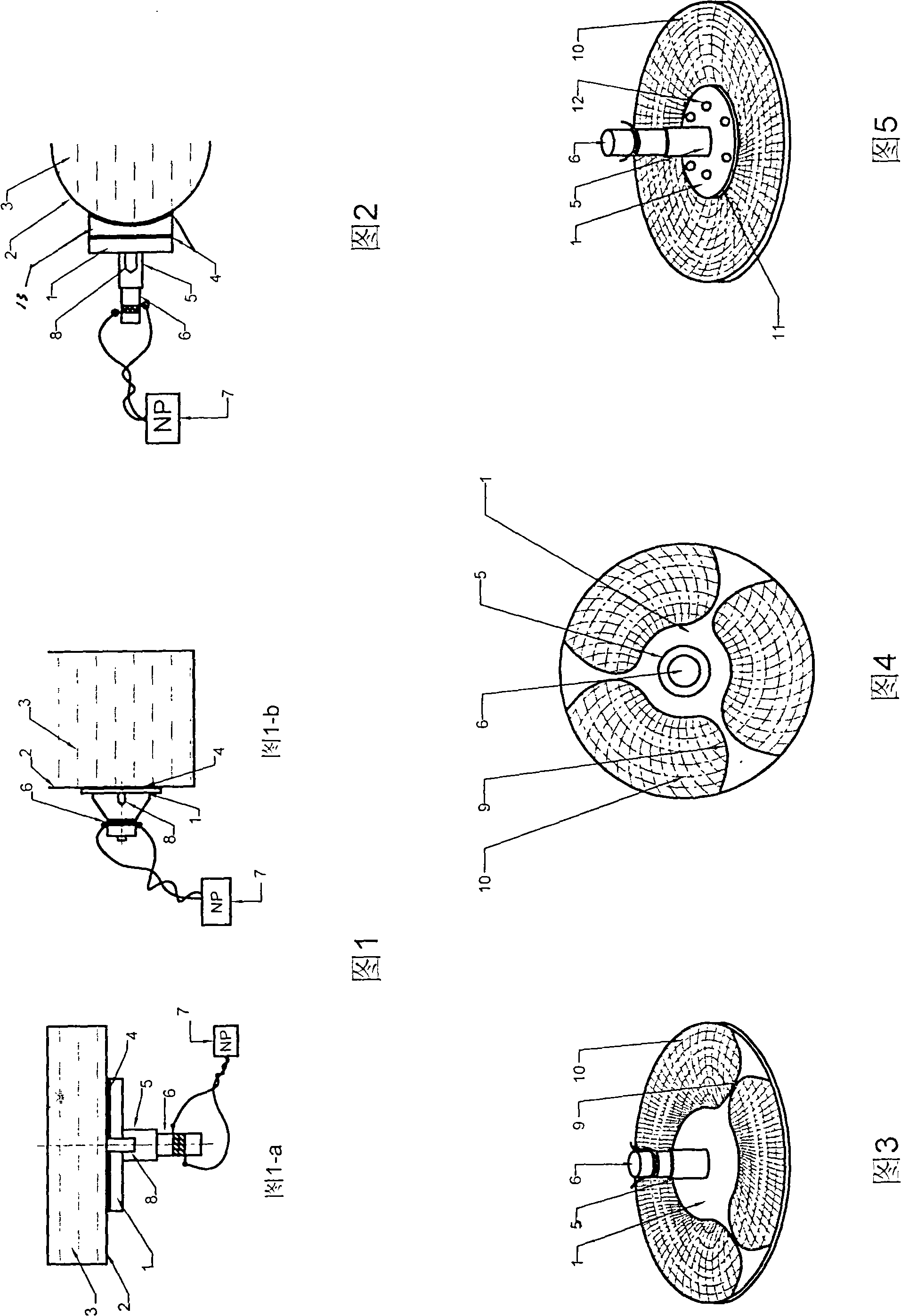

[0023] As shown in Figures 1 to 5, in Figures 1-a and 1-b, the power-expanding front metal vibration plate 1 and the horn 5 are arranged between the bottom plate 2 of the functional slot 3 and the transducer 6, and the variable The front end surface of the horn 5 is connected with the power-expanding front metal vibration plate 1 , and the rear end surface is connected with the front block of the transducer 6 . The screw 8 is vertically welded on the bottom plate 2, and screw holes corresponding to the size of the screw 8 are respectively set in the center of the metal vibration plate and the center of the horn before the power expansion. on the bottom plate 2. Adhesive 4 is applied between the pre-power expansion metal vibration plate and the bottom plate of the functional slot. When the central screw hole of the pre-power expansion metal vibration plate is screwed into the outer wall of the bottom plate of the function slot along the longitudinal direction of the screw, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com