Method for preparing dropping pill using cool air and equipment using the method

A technology of cooling air and dropping pills, which is applied in the direction of making medicines into special physical or taking form devices, dividing liquids into beads and granules, etc., which can solve the problem that the equipment cannot be completely cleaned, organic residues, and coolant residues cannot be solved. and other problems, to achieve the effect of no cleaning dead corners, conducive to stability, and beneficial products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

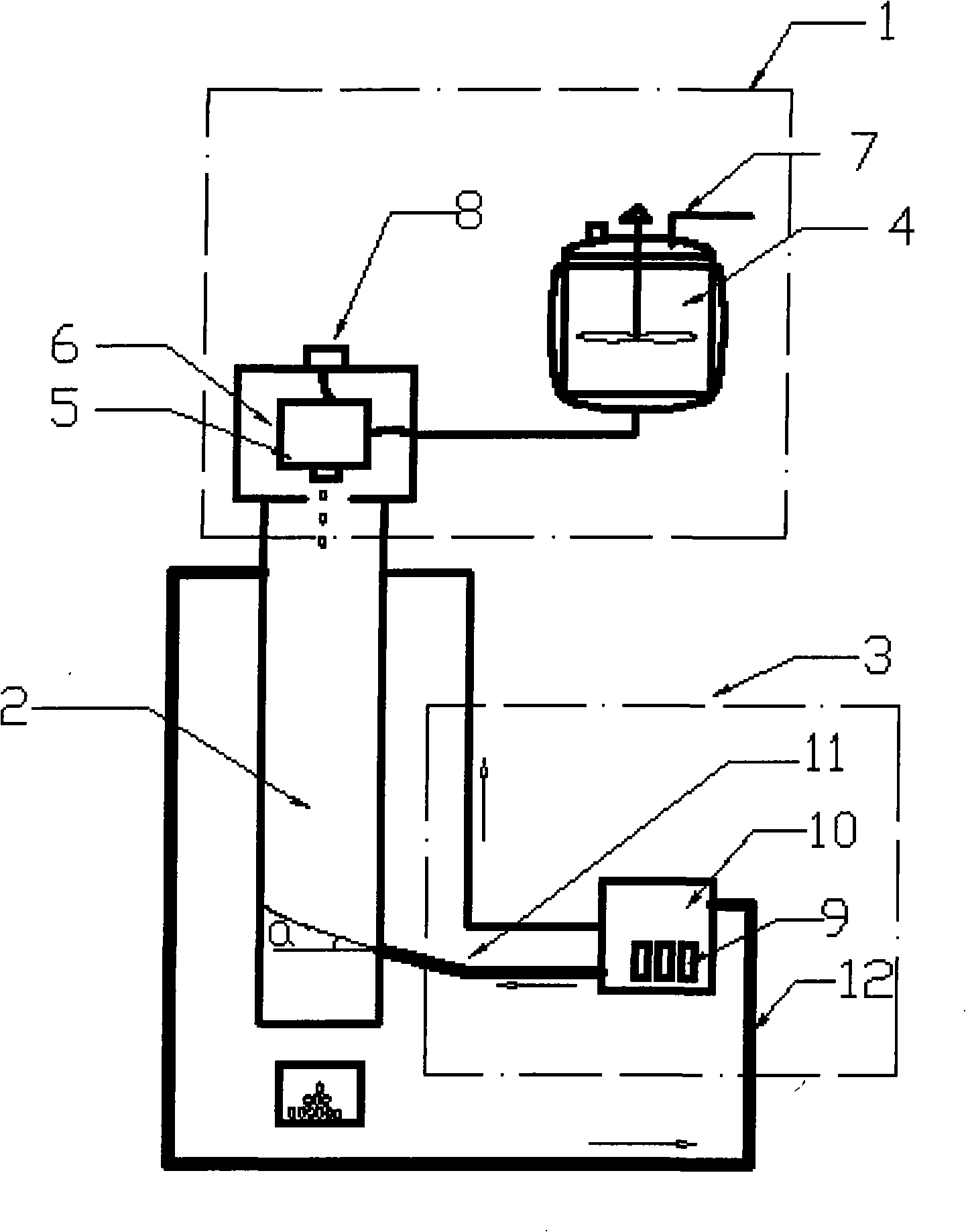

[0050] Example 1 prepares compound salvia miltiorrhiza dripping pills:

[0051] Get 600g of Danshen Sanqi extract, 5g of borneol, and 2000g of PEG-6000 auxiliary material. First add PEG-6000 into the chemical tank, heat it to 90°C, melt it in advance, then add the extract of Danshen notoginseng, mix well to form a liquid. Adjust the vibration frequency of the pneumatic vibrating dripper to 50Hz. The heat preservation room adopts a steam jacket for heat preservation, and the temperature is controlled at 80°C. The air pump sends air to the chemical tank through the pipeline, so that the above-mentioned liquid that has been melted evenly flows into the dripper and flows from the dripper. The bottom drips into the cooling pipe, and the cooling pipe is perpendicular to the ground; start the cold air to make the cooling temperature reach -20°C, the angle between the cooling air inlet and the horizontal plane is 45°, and make the cold air circulate in the cooling pipe, so that the dr...

example 2

[0052] Example 2 prepares Danshen dripping pills:

[0053] Take 600g of salvia miltiorrhiza extract, add 60g of water, add 1500g of PEG-6000 auxiliary material, put it into a chemical tank and heat to 90°C, make it completely melt and mix to form a liquid. Adjust the vibration frequency of the pneumatic vibrating dripper to 20Hz. The heat preservation room adopts infrared heating and heat preservation, and the temperature is controlled at 80°C. The air pump sends air to the chemical tank through the pipeline, so that the above liquid that has been melted evenly flows into the dripper and flows from the bottom of the dripper. Drop out into the cooling pipe; start the cold air while the above liquid is dripping out, make the cooling temperature reach -10°C, and make the cold air circulate in the cooling pipe, the angle between the cooling air inlet and the horizontal plane is 45°, so that the dripping The drops of medicine dripped from the head are cooled and solidified into sol...

example 3

[0054] Example 3 prepares Huoxiangzhengqi dripping pills:

[0055] Take Huoxiangzhengqi Extract 200g, Patchouli Oil 1ml, Perilla Leaf Oil 2ml, Polyethylene Glycol 600g, add it into the chemical tank at the same time, heat to 65-85°C, melt, mix evenly to form a liquid. Adjust the vibration frequency of the electric vibrating dripper to 200Hz. The heat preservation room adopts an electric heating jacket to keep warm. The bottom of the head drips into the straight cooling pipe; start the cold air at the same time as the above liquid drips out, so that the cooling temperature reaches -20°C, the angle between the cooling air inlet and the horizontal plane is 90°, and the cold air circulates in the cooling pipe , so that the drops of medicine dripped from the dripper are cooled and solidified in the cooling pipe to form solid pills, and then flow into the collection bucket from the outlet at the lower end of the cooling pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com