Method for improving exhaust air recovery tower efficiency and exhaust air recovery tower

A waste gas recovery and recovery tower technology, which is applied in the field of improving the efficiency of waste gas recovery towers and waste gas recovery towers, can solve the problems of increased raw material consumption, high absorption liquid temperature, and environmental pollution, and achieves simple structure, reduced emissions, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below with reference to the drawings.

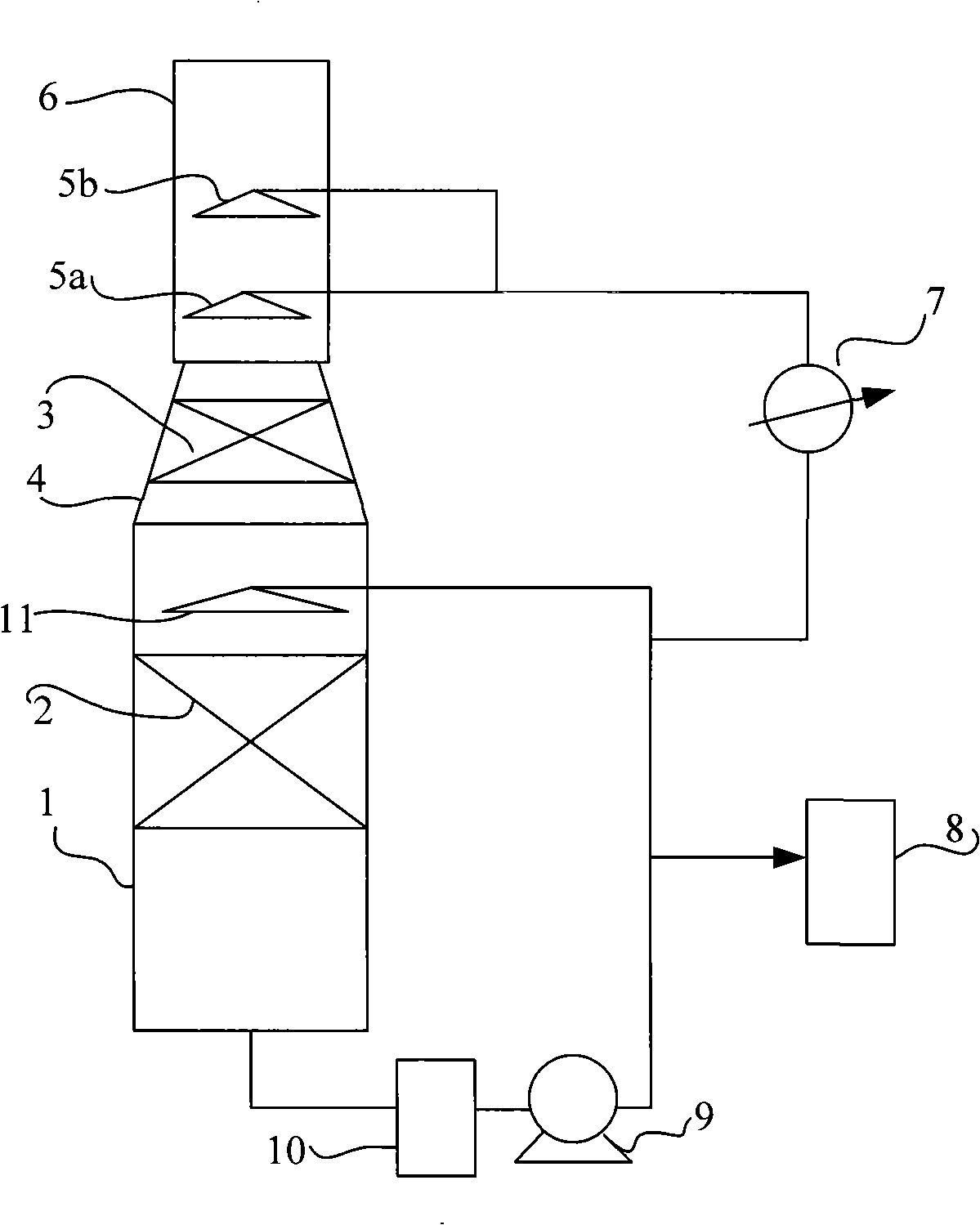

[0010] Such as figure 1 Shown is a schematic diagram of a waste gas recovery tower according to a preferred embodiment of the present invention. The waste gas recovery tower 1 of the present invention includes a packing layer 2 and a packing layer 3, wherein the packing layer 3 is arranged at the tower neck 4, two spray lines 5a and 5b are arranged in the chimney 6 above the packing layer 3, and the packing layer 2 is arranged above the packing layer 2. The spray line 11 and the waste gas recovery tower 1 also include a condenser 7. The waste gas recovery tower 1 is also connected with a storage tank 10, a pump 9 and a recovery tank 8.

[0011] After the exhaust gas entering the absorption tower 1 is absorbed by the packing layer 2, it continues to enter the packing layer 3 at the tower neck 4. The exhaust gas absorption liquid enters the absorption tower from the storage tank 10 via t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com