Yolk coal rock formation downward hole pumping and mining pressure relief mash gas construction method

A construction method and soft coal technology, applied in gas discharge, earthwork drilling, mining equipment, etc., can solve problems such as wind flow gas exceeding the limit, and achieve the effects of ensuring safe mining, increasing construction speed, and high hole formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

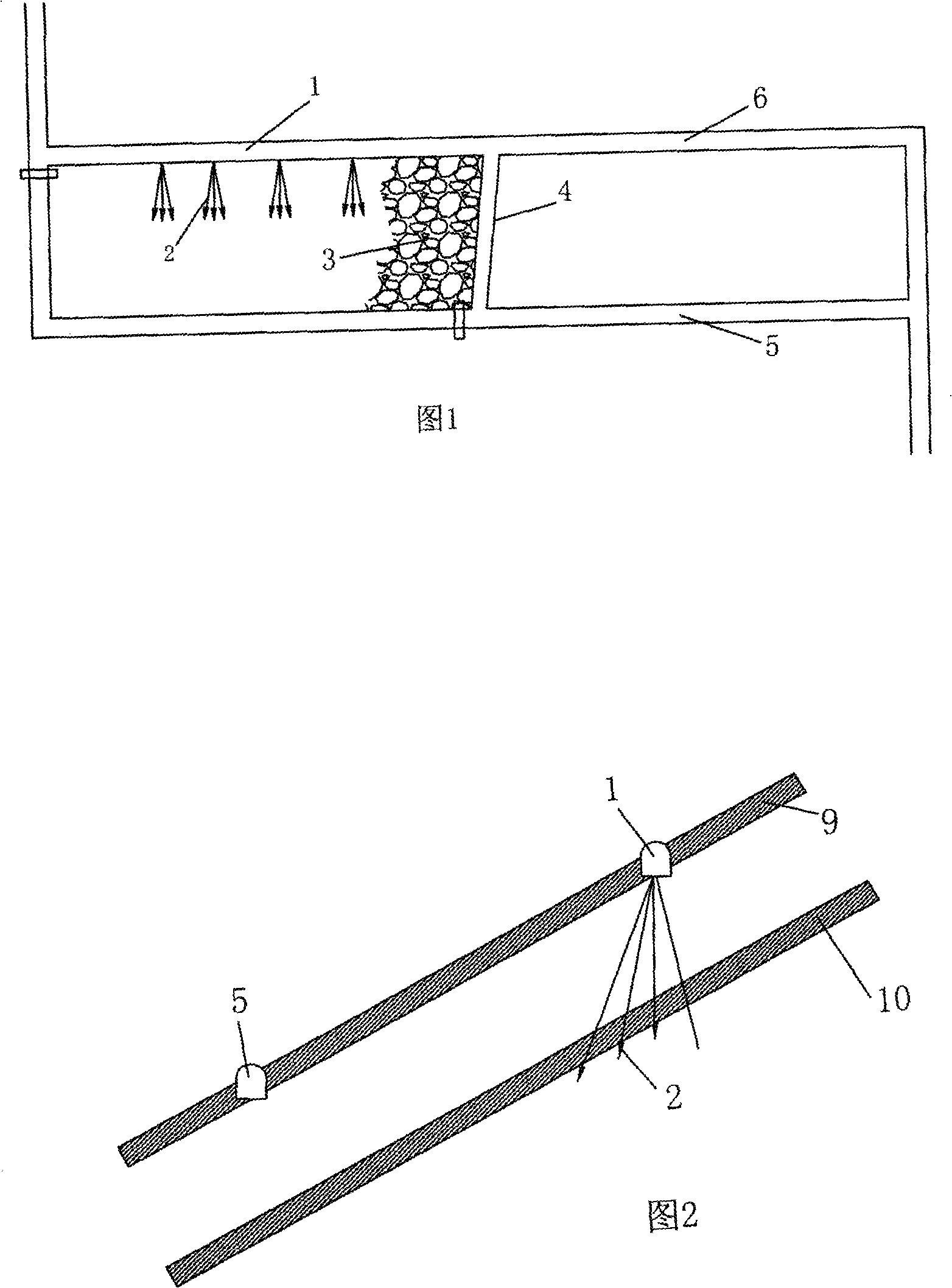

[0027] Referring to Figure 1, after the working face is put into production, the air tunnel will be filled with filling material to retain the tunnel for the second time during the mining period, as the return air tunnel of the face, and the air intake from the two lanes in the mining direction of the working face will be used to realize "two inlets and one air inlet". "Y" type ventilation

[0028] The main composition of the filling material in the roadway section is concrete paste, and the filling width x height is 3.0m x 1.8m. From the top to the bottom, the German BSM1002E new filling pump is used for filling. At the same time, for post-mining deformed roadways, supplementary shed support and undercover methods are adopted to ensure the section of the roadway retained along the gob.

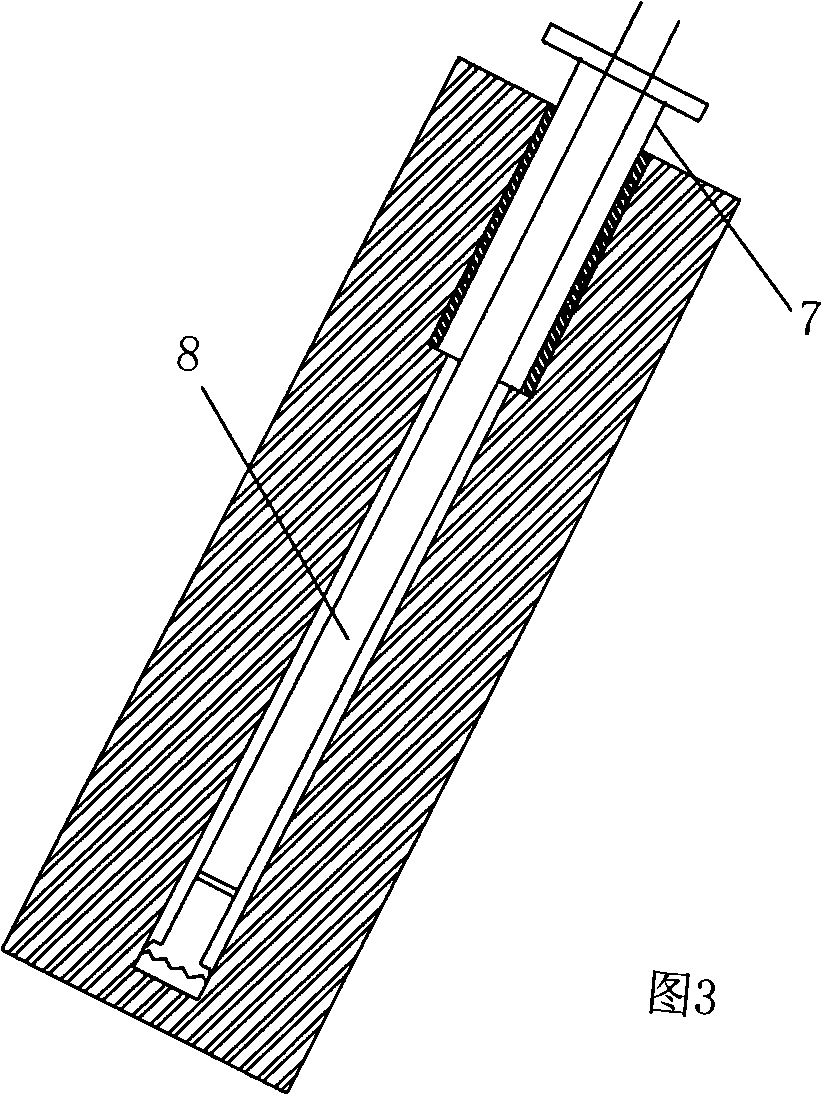

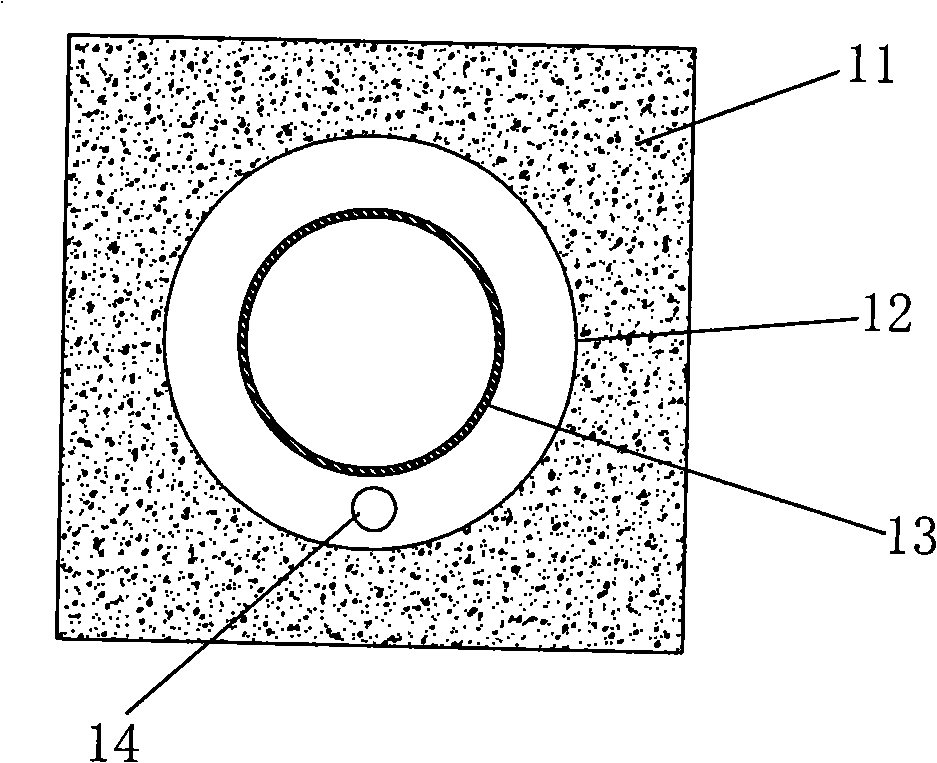

[0029] As shown in Fig. 1 and Fig. 2, gob-side retaining 1 is the roadway reserved along the goaf during the working mining process; the drilling construction angle of the downward-penetratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com