Cam disc for a shedding mechanism of a loom

A technology of cams and looms, which is applied to cam opening mechanisms, textiles, jacquard machines, etc., can solve troublesome and expensive problems, and achieve the effects of avoiding vibration and wear, and reducing force and load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

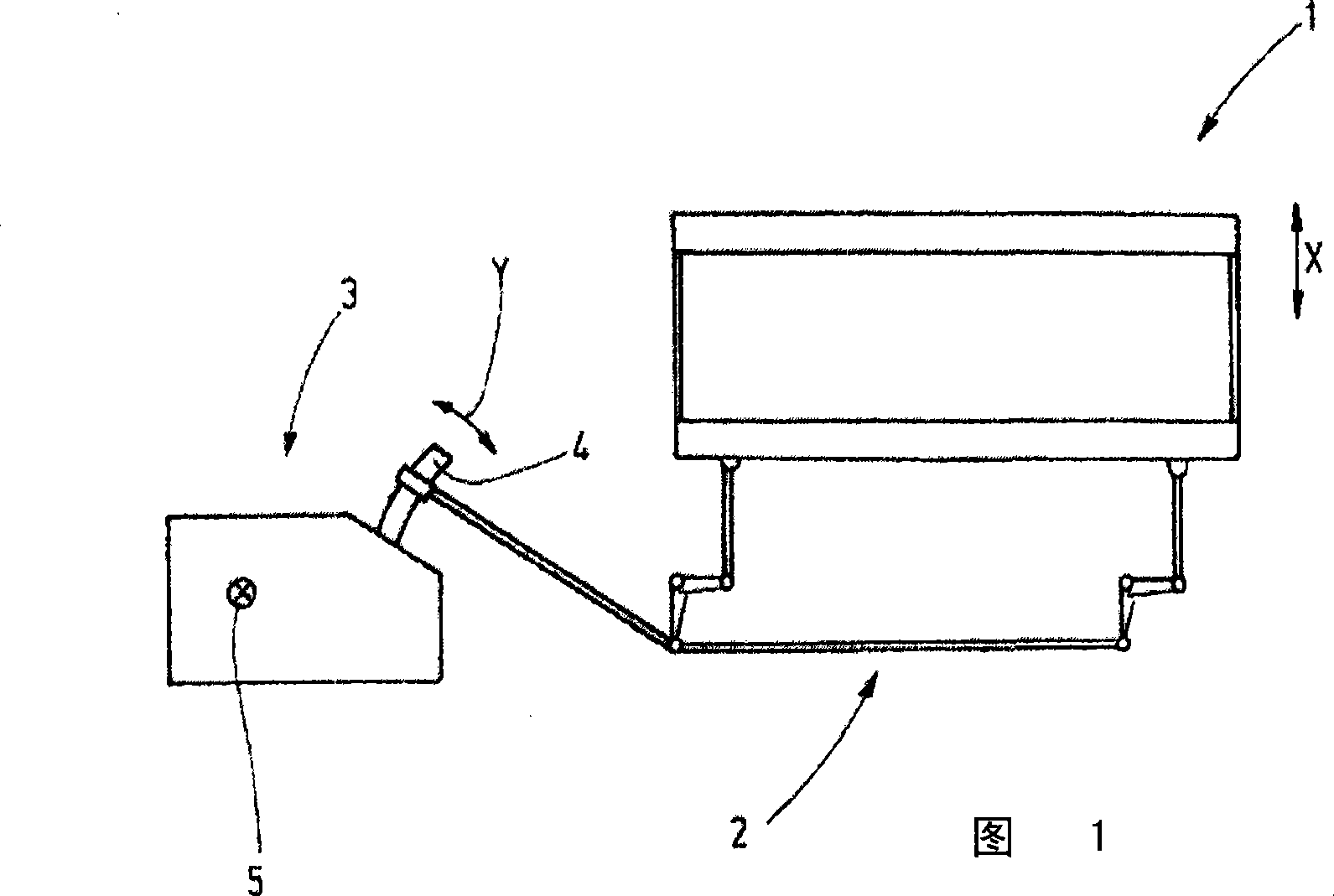

[0021] FIG. 1 shows a heald frame 1 which is driven by an eccentric device 3 via a connecting rod 2 in a vertically oscillating manner. The vertical direction indicated by the arrow is called the X direction. At its output, the eccentric device 3 has a rocker arm 4 which is connected to the connecting rod 2 . The rocker arm 4 executes a reciprocating vibrational movement, indicated by the arrow y in FIG. 1 , which is derived from the rotation of the main shaft 5 . The spindle is equipped with a drive, such as an electric motor, and rotates at a substantially constant rotational speed.

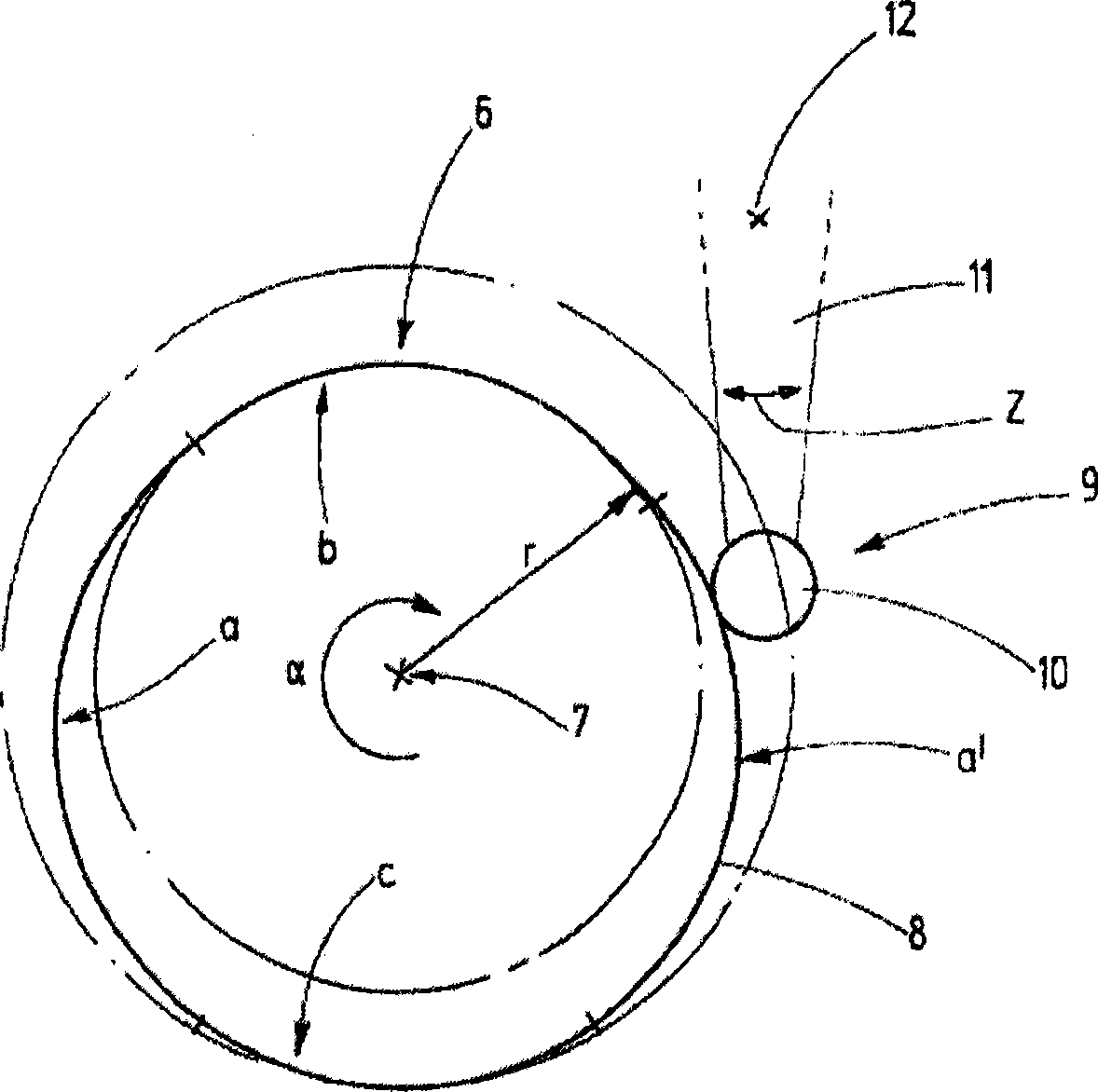

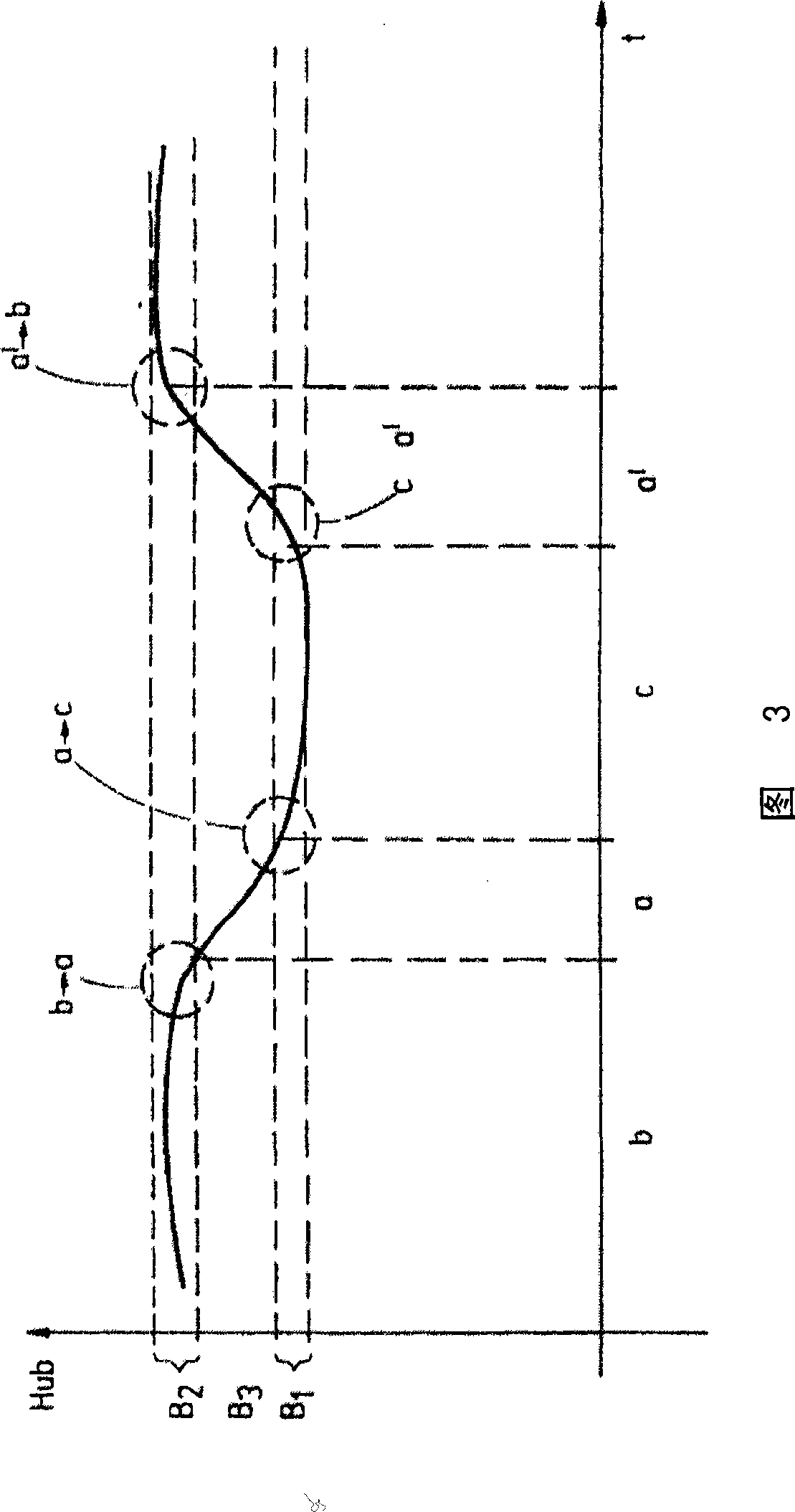

[0022] one such as figure 2 The cam 6 shown is located on the main shaft 5 . Its center of rotation 7 is determined by the main shaft 5 . It has a circumferential surface 8 whose radius r to the center of rotation 7 depends on the angle of rotation α. A cam follower 9 , for example in the form of a roller 10 bearing against the peripheral surface 8 , is supported by a rocker 11 . This roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com