Film preparation device and observation method for film growth

A technology for thin film preparation and thin film growth, which is applied to a device that forms a layer of thin film on the surface, indirectly observes the film formation process on the surface of the film, and observes the film growth. Affecting membrane performance and other issues, achieving the effect of simple structure, small opening and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is illustrated below in combination with embodiments and accompanying drawings.

[0020] The vacuum system and electrical system in the thin film preparation device of the present invention are the same as those of the prior art, and will not be described in detail here. Only the coating chambers of the present invention and the prior art are explained here.

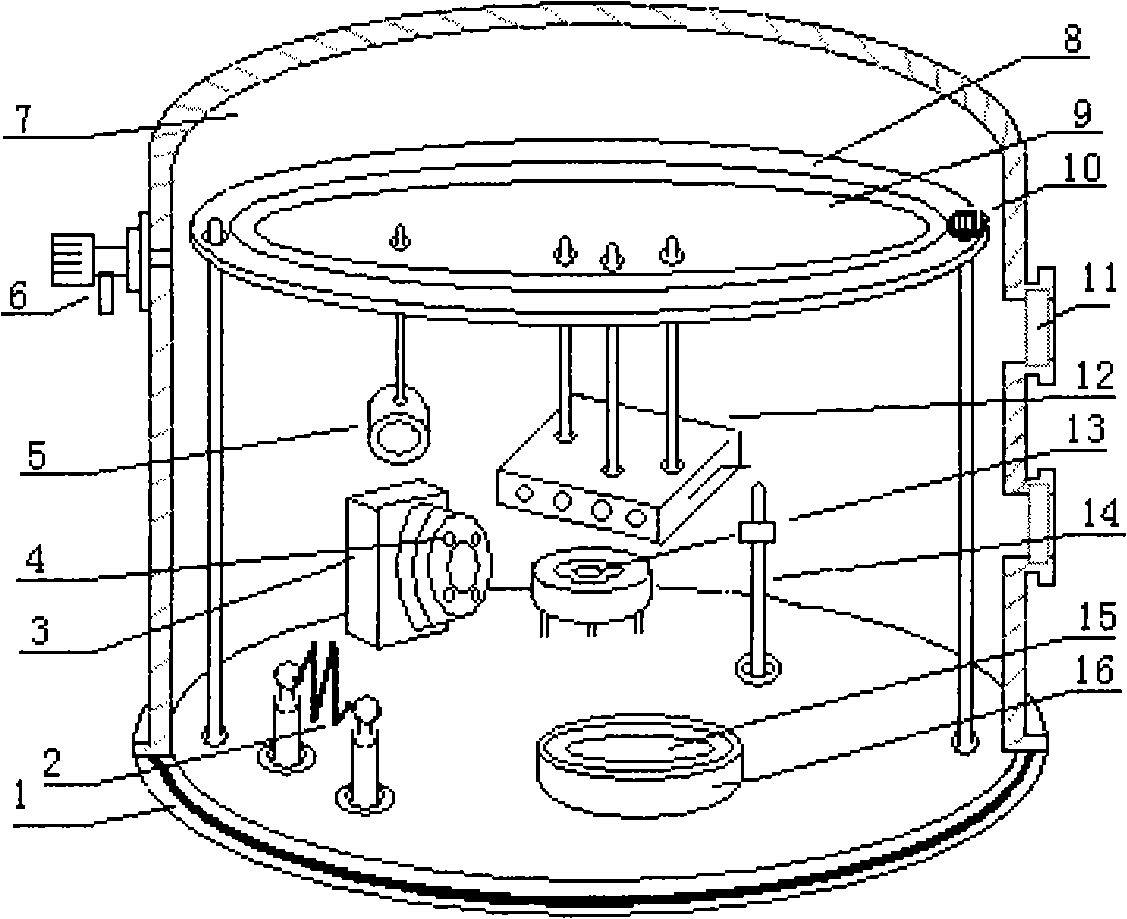

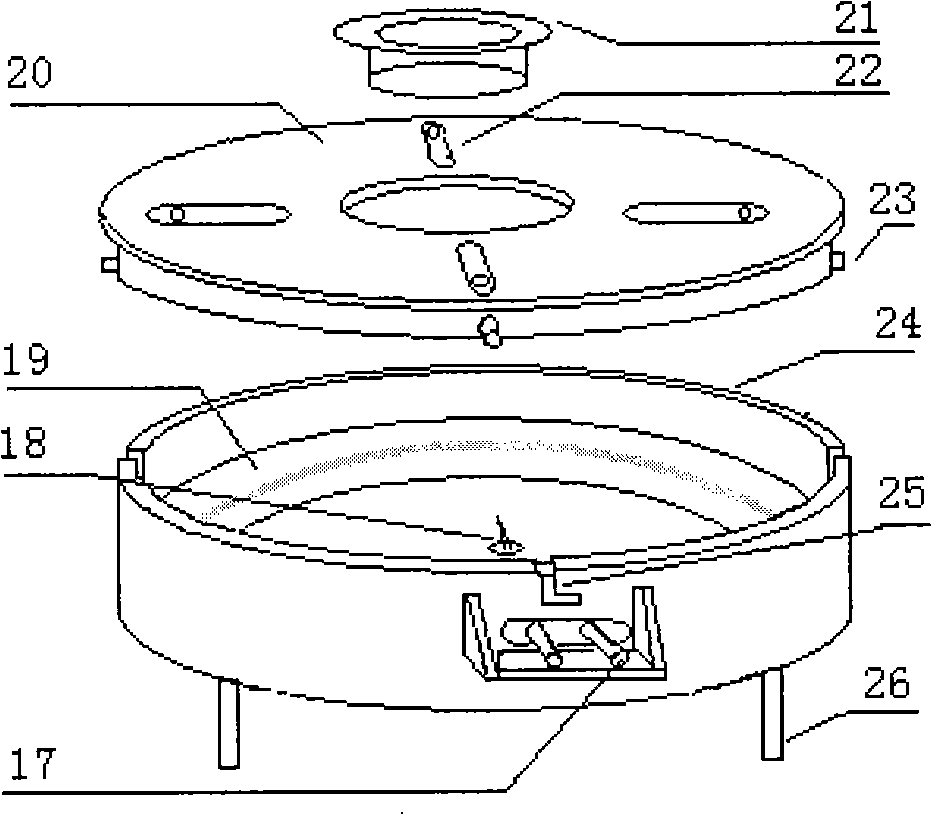

[0021] attached figure 1 It is a sectional view of an embodiment of the coating chamber of the present invention. Wherein: 2 is a resistance heating evaporator, 3 is a camera, 4 is an interference light source positioned next to the camera, 14 is used to set the rotating shaft of the rotating baffle (the baffle on it is not shown), and 15 is the sputtering target anode , 16 is the sputtering target cathode. These devices are all arranged on the bottom plate 1 of the coating chamber. Additionally, by figure 1 It can be seen that the radiant crucible evaporation heater 13 is fixed on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com