Transportation device

A conveyor and collision absorption technology, applied in the field of conveyors, can solve the problems of deterioration of collision absorption characteristics, easy collapse of collision absorption materials, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

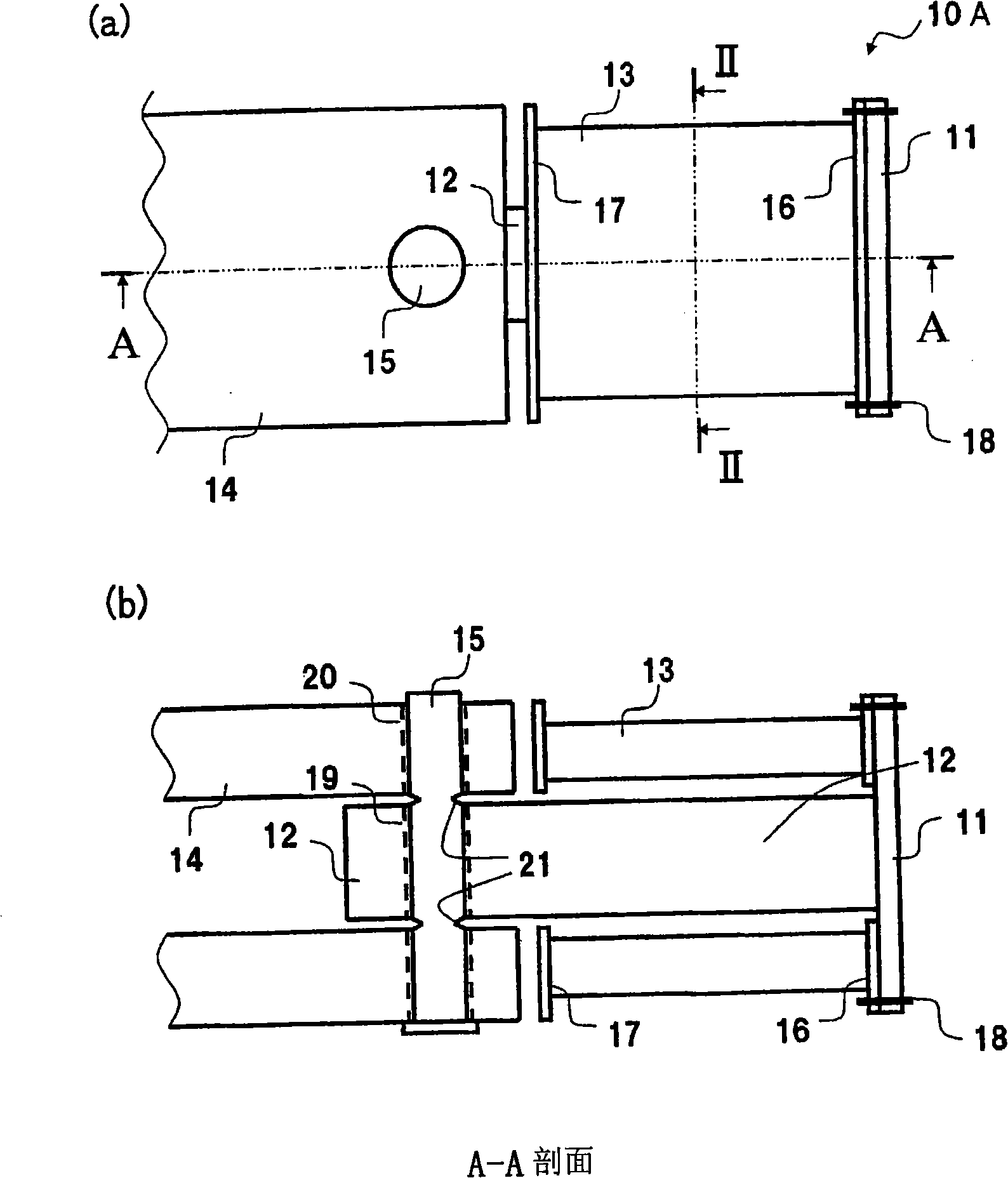

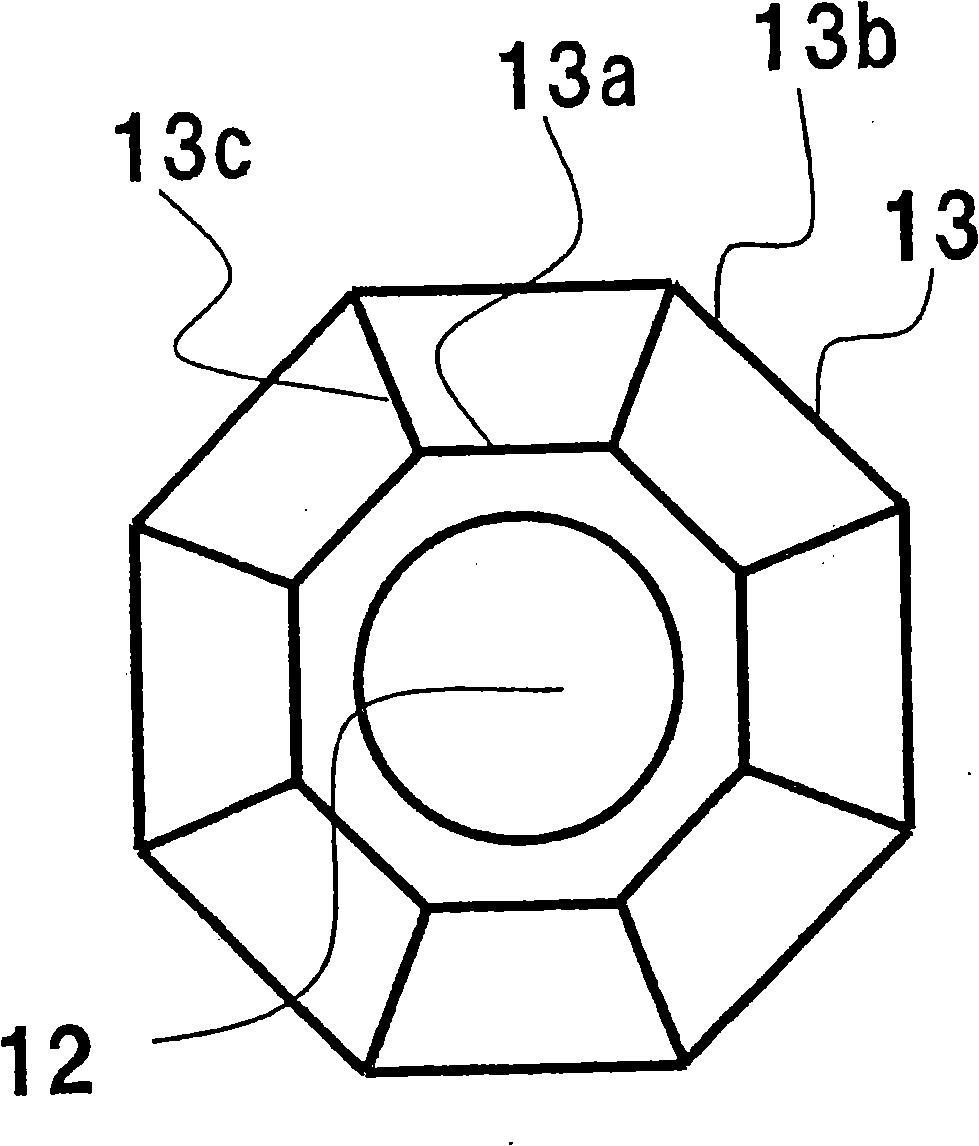

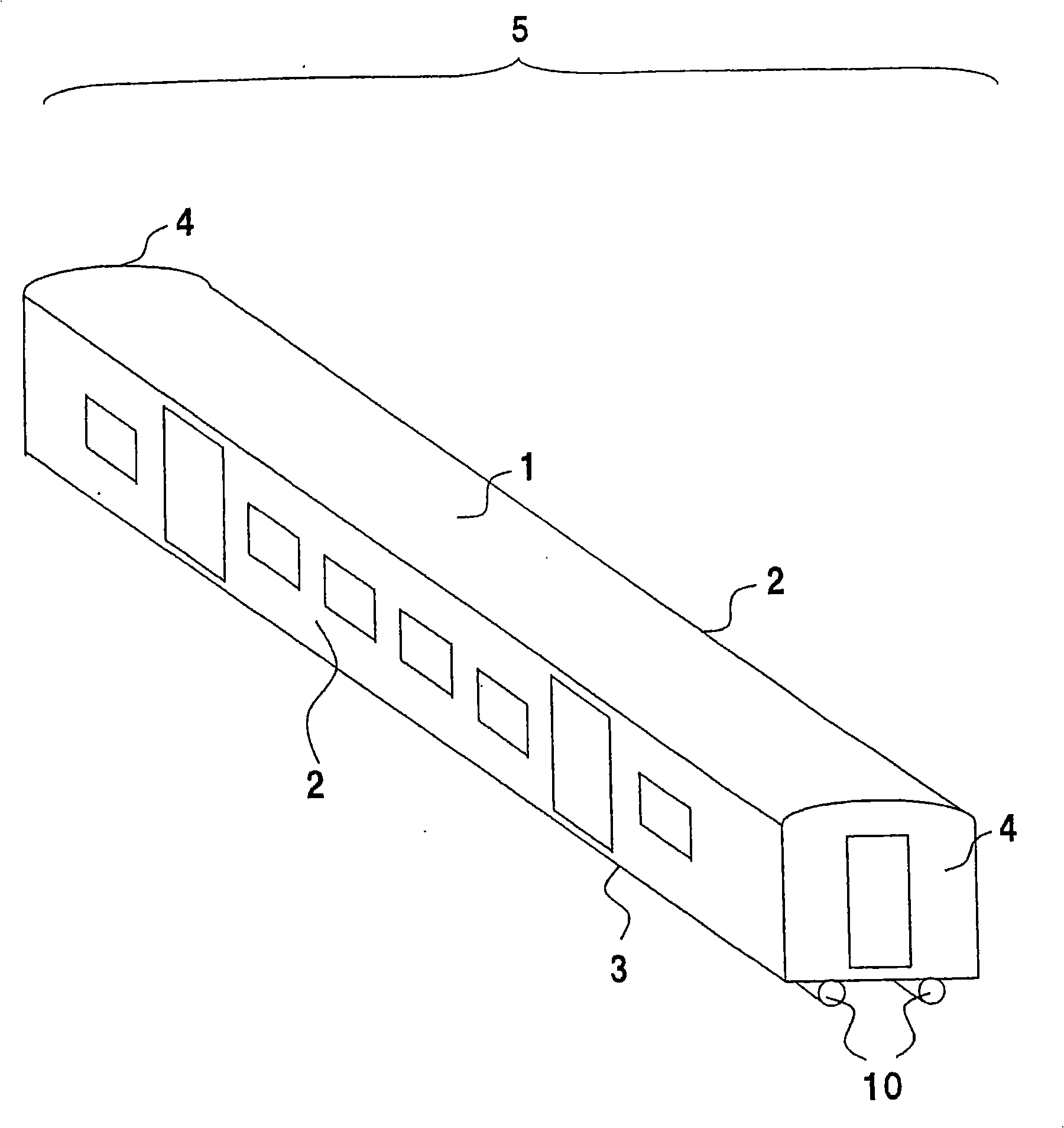

[0023] based on Figure 1 ~ Figure 3 An embodiment of the present invention will be described.

[0024] image 3 Among them, the railway vehicle body 5 is composed of a roof structure 1 constituting the upper surface, two side structures 2, 2 constituting the side faces, an underframe 3 constituting the lower face, and two end structures 4, 4 constituting the end faces. The roof structure 1, the side structures 2, 2, the underframe 3, and the end structures 4, 4 are formed by combining a plurality of extruded profiles. The extruded profiles constituting the end structure 1 , the side structures 2 , 2 , and the underframe 3 are hollow profiles made of aluminum alloy, and their extruded directions coincide with the front-rear direction of the railway vehicle structure 5 . The extruded profiles constituting the vehicle end structures 4 and 4 are ribbed profiles made of aluminum alloy, and the extruded direction is the same as the vertical direction of the railway vehicle struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com